High Efficiency: The Automated Water Cooling/Air Cooling Steel Curtain Belt Production Line is engineered for high efficiency. By integrating advanced cooling technologies, it ensures optimum production speeds while minimizing energy consumption. This feature makes the production line not only fast but also cost-effective, ideal for businesses aiming to maximize throughput and reduce operational costs.

Full-Automatic System: Designed with a fully automated system, this production line ensures high accuracy with minimal human intervention. The machine runs seamlessly, offering consistent product quality and maximum productivity. This automation drastically cuts down on downtime, boosts operational efficiency, and significantly reduces labor costs, providing a reliable solution for large-scale production.

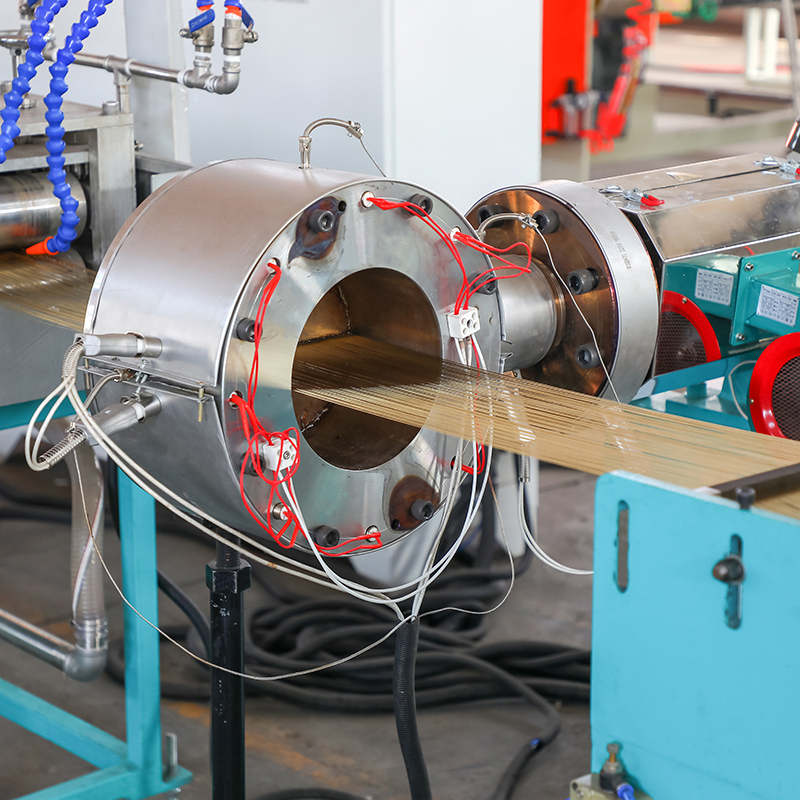

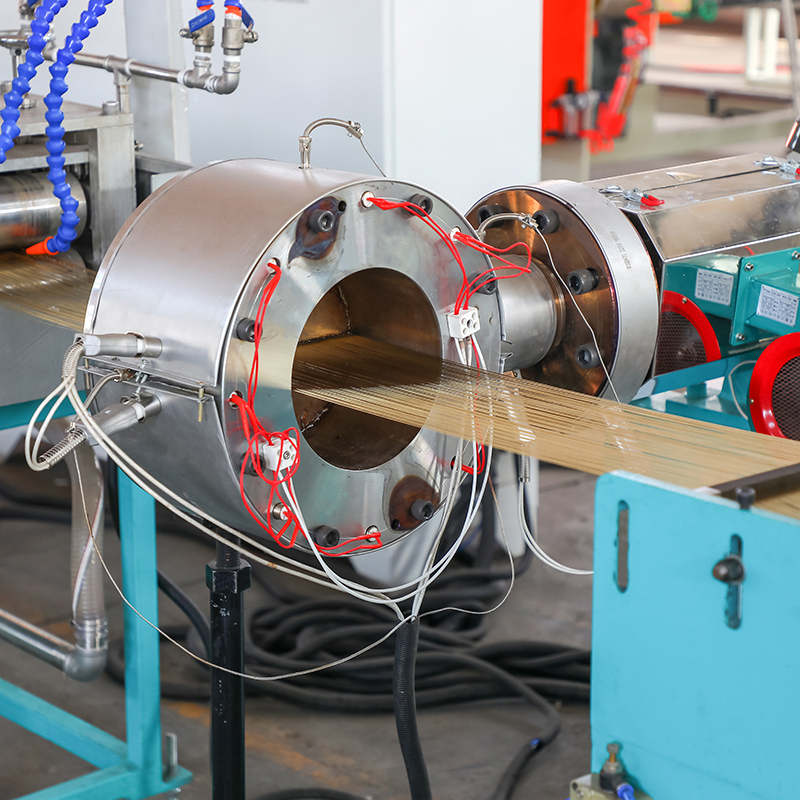

Durability and Longevity: Constructed from high-quality stainless steel, this machine is built for durability. The robust materials are resistant to corrosion and wear, guaranteeing that the steel curtain belt production line operates efficiently over an extended period. The durability ensures high efficiency with minimal maintenance, making it a long-term investment for any manufacturing facility.

Customizable Configurations: The Automated Water Cooling/Air Cooling Steel Curtain Belt Production Line offers customizable configurations to meet specific production requirements. Whether you need adjustments to machine size, weight, or the cooling type (water or air), the line can be tailored to fit your unique production environment. This flexibility ensures optimal performance while maximizing space efficiency and energy savings.

High-Speed Production: With a focus on high-speed operation, this production line is designed to handle large volumes in a short amount of time. The high-speed functionality allows businesses to meet demanding production schedules while maintaining the high accuracy needed to meet product specifications, making it ideal for industries requiring rapid output without compromising quality.

Energy Saving: The machine’s energy-saving technology ensures that the production process uses electricity efficiently, reducing energy consumption without affecting productivity. The incorporation of this technology not only lowers operational costs but also contributes to sustainable production, making it an environmentally friendly choice for businesses seeking energy-efficient solutions.

Hot Laminating Technology: With integrated hot laminating technology, this production line ensures precise bonding and cutting of steel curtain belts. This technology allows for high precision in product output, ensuring a high-quality finished product that meets industry standards. The hot laminating process also enhances the durability and strength of the steel belts, making them more reliable for long-term use in demanding environments.

Manufacturer Expertise: With years of experience, Zhongrui Machinery is a trusted manufacturer of advanced steel curtain belt production lines.

Cost-effective: Energy-saving and durable materials help reduce operational costs in the long term.

High-speed and precision: Offers high-speed processing and high-accuracy cutting, ensuring uniform and consistent product quality.

Durability: Built to last, the machine uses corrosion-resistant materials and features a robust cooling system to handle demanding industrial environments.

Multi-functional: Ideal for use in industries such as food packaging, steel production, and material handling, making it a versatile solution for different production needs.

Efficient After-Sales Support: Zhongrui Machinery offers comprehensive online technical support to ensure smooth operations.

Cost-Effective Solutions At Zhongrui Machinery, we manufacture all our machines in-house to minimize production costs. By eliminating intermediaries, we pass on the savings directly to our customers, offering affordable prices without compromising quality.

Genuine Products with Exceptional Quality We maintain strict quality control standards when selecting materials for production. Every material that enters our factory undergoes thorough testing to ensure only the highest quality components are used. Any substandard materials are promptly returned to the supplier, ensuring that our customers receive only premium products.

Global Engineering Support Our team of skilled engineers is available to provide overseas support. Whether you need assistance with installation, maintenance, or troubleshooting, our experts are ready to offer personalized support wherever you are.

Timely Delivery With a streamlined supply chain and efficient production processes, we ensure on-time delivery for all orders. Our just-in-time delivery system guarantees that your machinery reaches you when you need it, minimizing delays and keeping your production schedules on track.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province