PP Fiber Packaging Belt Production Line

![纤维打包带生产线7_副本 纤维打包带生产线7_副本]()

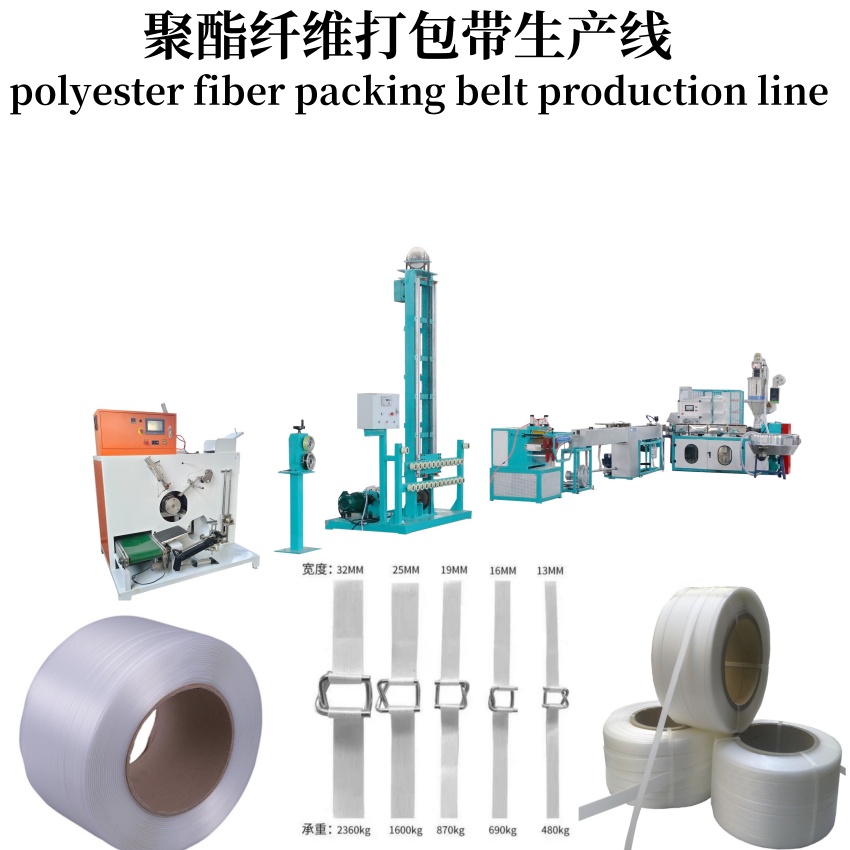

The fibre strapping production line is a highly efficient and advanced manufacturing system designed to produce high-quality fibre strapping bands, which are widely used for packaging, securing cargo, and reinforcing various materials. These strapping bands are made from materials such as polypropylene (PP), polyethylene (PE), and polyester (PET), offering a range of benefits over traditional steel strapping.

We manufacture fiber packaging belt production lines built for high throughput, consistent web formation and gentle handling of textile, nonwoven and composite fiber materials. Our solutions serve packaging suppliers producing conveyor belts, protective wraps, filter media carriers and industrial webbing used in logistics and manufacturing. I collaborate with our R&D team to specify melt extrusion and calendaring modules, take-up systems and inline winding technologies so you receive belts with tight width tolerance, uniform thickness and reliable bonding between layers.

Why choose a Fiber-Packaging-Belt Production Line from us?

You want a line that minimizes waste while delivering repeatable physical properties. Our designs focus on energy-efficient extrusion, accurate speed synchronization and robust tension control to preserve fiber orientation and mechanical integrity. We build modular lines that allow rapid conversion for different belt widths and material blends, and we provide clear O&M documentation so your operators can maintain high uptime.

Whether you are scaling up a new production run or replacing aging equipment, our engineers help select the correct extruder configuration, roller geometry and annealing strategy to hit target mechanical strength and elongation values. We also offer lifecycle service options and spare parts to keep throughput stable. See the full technical scope and production examples on our dedicated product listing or Contact us to request a tailored proposal.

Key Features of the Fibre Strapping Production Line

1. High Strength and Durability:

- Fibre strapping bands are as strong as steel but lighter in weight, making them easier to handle and transport. They can absorb vibrations and impact, ensuring the safety of goods during long-distance transportation.

2. Environmental Resistance:

- These bands are resistant to chemicals, do not rust or rot, and can withstand various weather conditions. They are also recyclable, making them an environmentally friendly choice.

3. User-Friendly and Safe:

- Unlike steel strapping, which can cause injuries, fibre strapping bands are safe to handle and do not damage products. They are also lightweight and portable, making them convenient for use in different environments.

4. Cost-Effective:

- Fibre strapping bands are cost-effective and can be produced using recycled materials, reducing production costs. They also eliminate the need for additional tools or energy sources, further lowering operational expenses.

5. Customization Options:

- The production line allows for customization of the strapping bands, including width, thickness, and even printing of company logos. This makes them ideal for branding and marketing purposes.

6. Advanced Manufacturing Technology:

- The production line features high-speed and stable production capabilities, with line speeds reaching up to 200 meters per minute. It also includes precision manufacturing processes, low noise levels, and high yield.

7. Safety and Compliance:

- The equipment is designed to strictly comply with safety standards, ensuring a safe working environment. It also features a high degree of automation and humanized design, making it easy to operate and maintain.

Production Process

The production process of fibre strapping involves several key steps:

- Raw Material Preparation: High-quality PP, PE, or PET fibres are selected as the main raw materials.

- Extrusion and Forming: The fibres are extruded and formed into strapping bands using advanced extrusion machines.

- Stretching and Cooling: The bands are stretched and cooled to ensure their strength and durability.

- Embossing and Finishing: The bands may undergo embossing to enhance their grip and appearance.

- Winding and Packaging: The final strapping bands are wound onto spools and packaged for distribution.

Applications

Fibre strapping bands are widely used in various industries, including:

- Packaging and transportation

- Reinforcement of materials such as geotextiles and pipelines

- Securing heavy loads in industries like steel, aluminum, and paper

| Bandwidth range | 13-32mm |

| Linear speed | 120m/min |

| Motor power | 37KW |

| Extrusion capacity | 150-180kg/h |

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province