![11_副本_副本]()

The PC/PMMA/PE/PP/PS/ABS plastic sheet/plate extrusion production line can continuously produce single or multi-layer sheets/plates, with a width usually less than 3000mm and a thickness range of 0.1-30mm (depending on the material). It is widely used in fields such as refrigerators, air conditioners, automobiles, advertising, construction, and environmental protection.

The main materials, such as PC (polycarbonate), feature high strength, high transparency, and impact resistance, and can be used in fields like advertising light boxes, architectural decoration, and safety lighting. PMMA (acrylic) is used in instrument panels, lighting, decoration, construction, etc. ABS, PS and other sheet materials are suitable for fields such as electronic product packaging and vacuum packaging

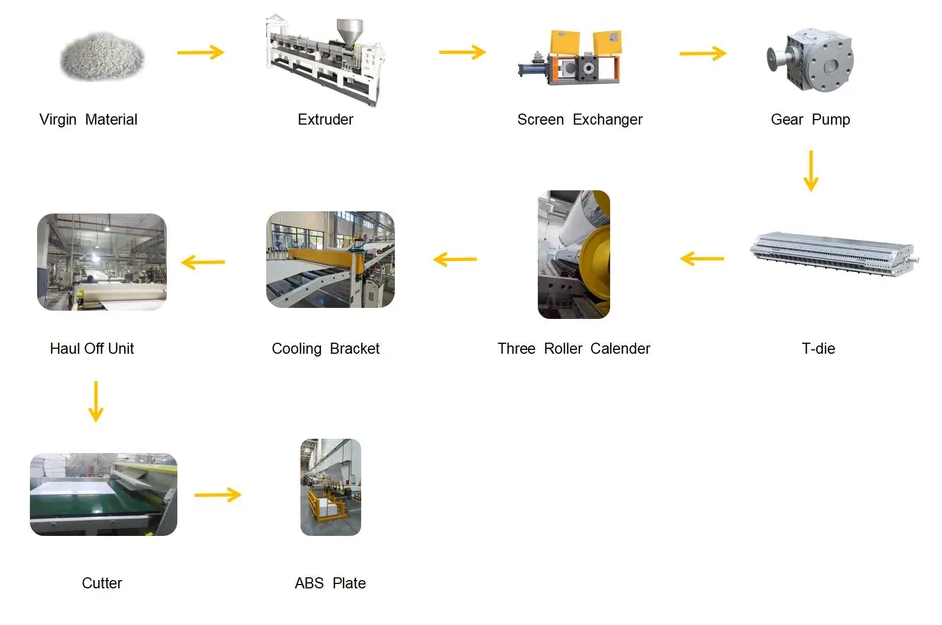

Process Flow:

Feeder→ Extruder → Mould →three roller calender → Haul-off → Cutter →auto winder

(Note: Other Auxiliary Machine, such as Crystallizer,dryer,crusher, mixer, etc. will be provided according to client's requirements)

![微信图片_20241127095136]()

Main technical parameters

| Model | SJ130/36 | SJ120/36 |

| Material | PC/PMMA/PE/PP/PS/ABS | PC/PMMA/PE/PP/PS/ABS |

| Products Width | 2200mm | 1220mm |

| Products Thickness | 1.5-10mm | 1.5-10mm |

| Extruder Specification | Φ130/36; Φ45/30 | Φ120/36 |

| Capacity(Max.) | 550kg/h | 450kg/h |

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province