Overview

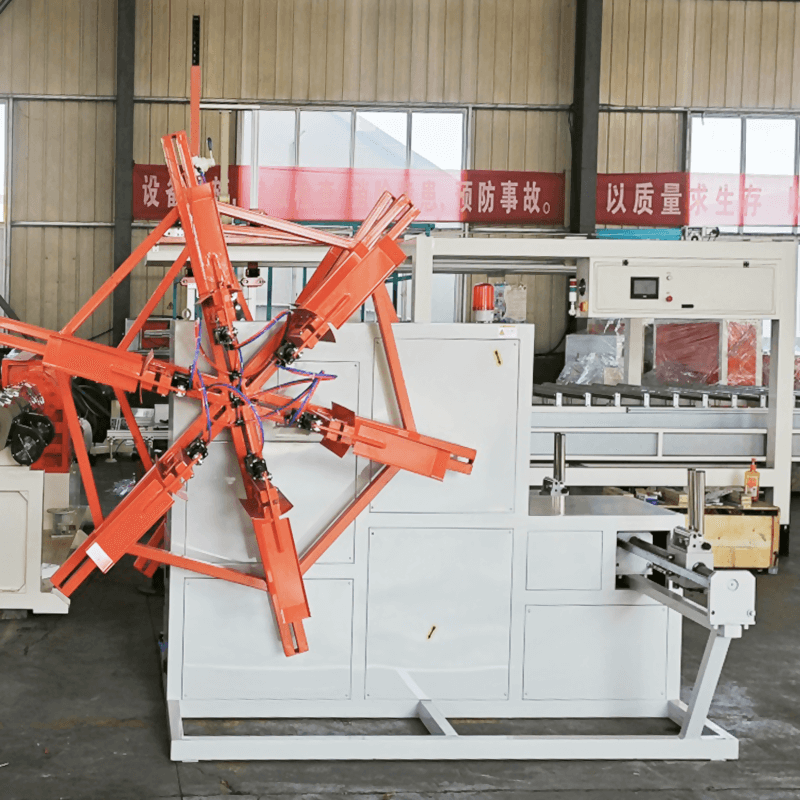

Our PE/PPR Pipe Production Line is a cutting - edge manufacturing solution that combines innovation, efficiency, and flexibility to produce high - performance PE and PPR pipes. Engineered to meet the evolving demands of the construction, plumbing, and industrial sectors, this production line offers a comprehensive solution for producing pipes with a wide range of sizes, thicknesses, and properties. From the initial feeding of raw materials to the final packaging of the finished pipes, every step of the production process is optimized to ensure the production of pipes that are not only of superior quality but also cost - effective.

Features

• Customizable Production Capability: One of the key features of our production line is its high degree of customization. Manufacturers can easily adjust various production parameters through the control system, such as pipe diameter (ranging from 16mm to 1200mm), wall thickness, and material type (PE or PPR). The line supports the production of pipes with different pressure ratings, from low - pressure pipes for general water supply to high - pressure pipes for industrial applications. This flexibility allows manufacturers to meet the diverse needs of their customers and adapt to different market demands.

• Energy - Saving and Environmentally Friendly Design: We prioritize energy efficiency and environmental protection in the design of our production line. The heating system of the extruder uses advanced energy - saving technologies, such as electromagnetic induction heating, which reduces energy consumption by up to 30% compared to traditional heating methods. Additionally, the production process generates minimal waste, and the use of recyclable PE and PPR materials aligns with sustainable manufacturing practices. The line also features a waste recycling system that can collect and reuse scrap materials, further reducing environmental impact.

• High - Speed and High - Capacity Production: With an optimized production process and powerful machinery, our PE/PPR Pipe Production Line can achieve high - speed and high - capacity production. It can produce pipes at a rate of up to [X] meters per minute, depending on the pipe specifications. This high - production capability allows manufacturers to fulfill large - volume orders promptly, enhancing their competitiveness in the market and meeting the growing demand for PE/PPR pipes.

Applications

• Building Construction: In building construction projects, PE/PPR pipes are used for various applications, including water supply, drainage, and heating systems. Our pipes' excellent performance and long service life make them ideal for both residential and commercial buildings. Their easy installation and low maintenance requirements also contribute to cost savings during the construction and operation of buildings.

• Municipal Engineering: Municipal engineering projects, such as water supply networks, sewage treatment systems, and irrigation projects, rely on PE/PPR pipes for their reliable performance and durability. Our production line can produce large - diameter pipes suitable for municipal infrastructure, ensuring the efficient transportation of water and wastewater. The pipes' resistance to corrosion and abrasion also reduces the need for frequent replacements, saving maintenance costs for municipal authorities.

• Renewable Energy Systems: In renewable energy systems, such as geothermal heating and cooling systems and solar water heating systems, PE/PPR pipes play a crucial role in transporting heat - transfer fluids. Their high - temperature resistance and chemical stability make them suitable for these applications, ensuring the efficient operation of renewable energy systems and contributing to the global transition towards sustainable energy sources.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province