Overview

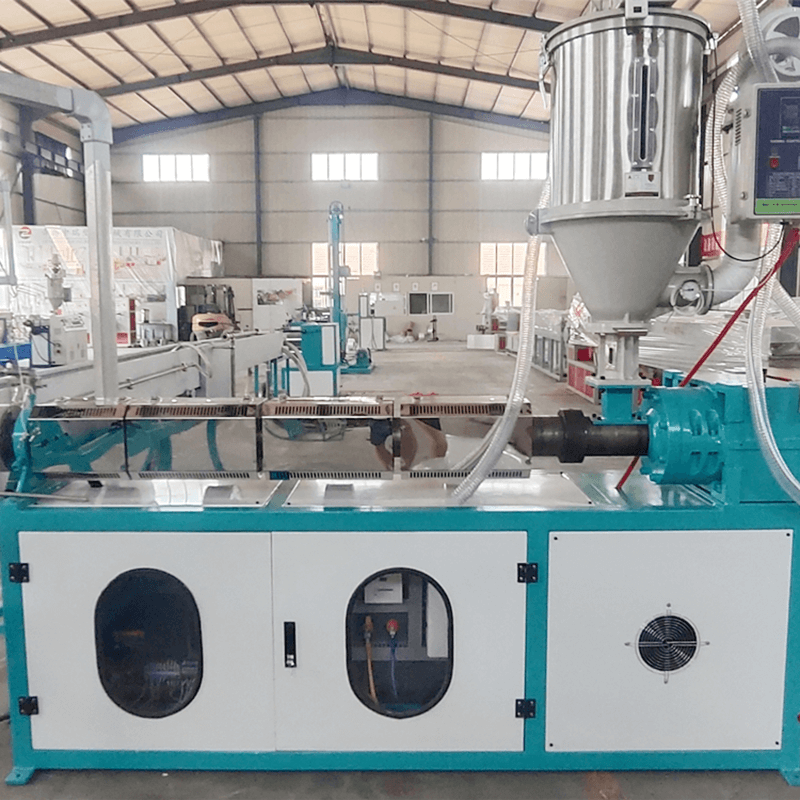

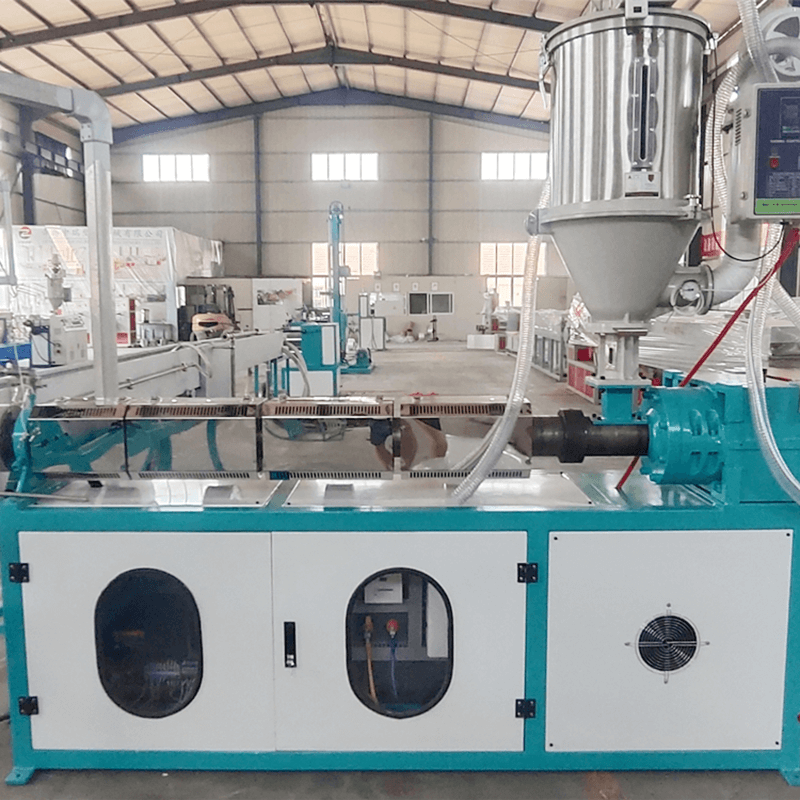

Our Fiber Packaging Belt Production Line is a state - of - the - art manufacturing solution meticulously engineered to meet the growing demands for high - quality, eco - friendly packaging materials. Fiber packaging belts, renowned for their strength, durability, and recyclability, have become an essential component in various industries' packaging processes. This production line integrates a series of advanced processes, from raw material preparation to the final product formation, all managed by an intelligent control system. It is designed to handle different types of fiber materials, such as polypropylene fiber, polyester fiber, and natural fiber blends, enabling the production of belts with diverse properties. Whether you are a small - scale packaging material producer aiming to expand your product range or a large - scale manufacturer seeking to enhance production efficiency, our Fiber Packaging Belt Production Line offers a reliable and cost - effective solution.

Features

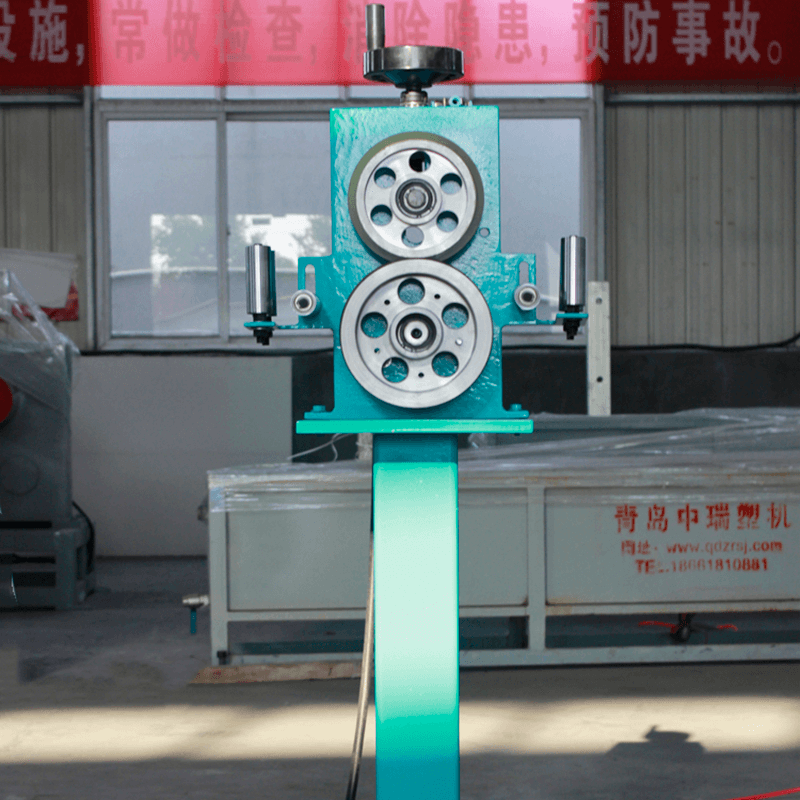

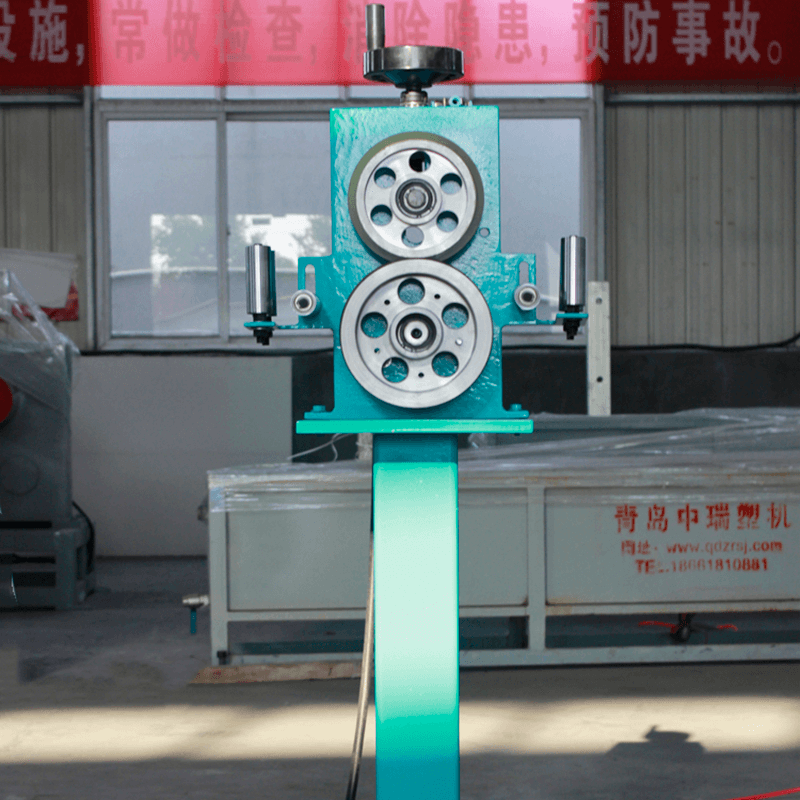

• High - Precision Extrusion and Drawing System: At the heart of our production line lies the high - precision extrusion and drawing system. Equipped with advanced screw and barrel configurations, it can precisely control the melting and extrusion of fiber materials, ensuring uniform material flow. The drawing process, which follows extrusion, utilizes a series of heated rollers and tension control mechanisms to enhance the belt's strength and dimensional stability. With this system, we can produce fiber packaging belts with consistent thickness and tensile strength, with a thickness tolerance of ± 0.1mm and a tensile strength variation within 5%.

• Automated and Flexible Production: The production line is highly automated, reducing manual labor and minimizing human errors. A programmable logic controller (PLC) system coordinates the entire production process, automatically adjusting parameters such as extrusion speed, drawing ratio, and cooling temperature according to different product specifications. Moreover, the line features quick - change die heads and adjustable cutting devices, allowing for easy switching between different belt widths and lengths. This flexibility enables manufacturers to respond promptly to various customer demands and market trends.

• Energy - Saving and Environment - Friendly Design: We prioritize energy efficiency and environmental protection in the design of our production line. The heating system uses advanced energy - saving technologies, such as electromagnetic induction heating, which reduces energy consumption by up to 30% compared to traditional heating methods. Additionally, the line is designed to minimize waste generation, with a recycling system that can collect and reuse scrap materials. The use of eco - friendly fiber materials in the production process further contributes to a sustainable packaging solution.

Applications

• Logistics and Warehousing: In the logistics and warehousing industry, fiber packaging belts are widely used for securing goods during transportation and storage. Our high - strength belts can withstand heavy loads and rough handling, ensuring the safety of packaged items. Whether it's bundling pallets of consumer goods, industrial products, or agricultural produce, our fiber packaging belts provide a reliable and cost - effective strapping solution.

• Manufacturing and Assembly: Manufacturing plants rely on fiber packaging belts to bundle components and finished products for shipping. The belts' excellent resistance to abrasion and chemicals makes them suitable for packaging a wide range of items, from metal parts and machinery components to electronic devices. Their flexibility also allows for easy application around irregularly shaped objects.

• Agriculture and Forestry: In the agriculture and forestry sectors, fiber packaging belts are used to bundling crops, hay bales, and lumber. The belts' resistance to moisture and UV radiation ensures long - term durability, even in outdoor environments. Their recyclability also aligns with the sustainable practices often emphasized in these industries.

![Fiber Packaging Belt Production Line Fiber Packaging Belt Production Line]()

Material and Performance

The High-capacity Fiber Strapping Production Line is designed to produce high-strength fiber straps using materials such as PP (Polypropylene), PET (Polyethylene Terephthalate), and fiber. These materials are known for their excellent durability and high tensile strength, ensuring the straps produced are capable of securing heavy-duty loads in various industries.

Material Quality: The production line uses high-quality raw materials to guarantee the straps’ reliability. Whether used for packaging or construction, the straps offer robust performance under pressure.

Performance Consistency: The machine ensures consistent production quality with minimal variations, providing uniformity in strap width and thickness. This consistency is critical in high-volume production environments, ensuring that the straps meet the required standards every time.

Adaptability: The machine is capable of adjusting to different materials, allowing for flexible production without compromising on quality. This adaptability makes it suitable for various industries and applications.

Product Quality Control

Ensuring the highest quality is an integral part of our manufacturing process. The High-capacity Fiber Strapping Production Line undergoes rigorous quality control checks at every stage of production to guarantee consistent performance.

Material Inspection: We inspect all raw materials before they enter the production process to ensure they meet the required specifications for strength and durability.

Precision Manufacturing: Each component of the machine is manufactured with precision to ensure reliable operation and the production of high-quality straps.

Final Testing: After assembly, the entire system undergoes comprehensive testing, including performance, efficiency, and safety checks. Only products that pass all tests are shipped to customers.

Certification: Our machines are certified to meet industry standards for safety, quality, and performance, providing customers with the assurance of high-quality equipment.

Packaging

The High-capacity Fiber Strapping Production Line is carefully packaged to prevent damage during shipping and ensure it arrives in excellent condition. We use durable packaging materials such as:

Metal Case: To protect the machine from physical damage during transit.

Wooden Case: For additional support and to ensure the equipment remains secure.

Plastic Tubes: For the safe transport of smaller components or consumables.

Each unit is labeled with clear instructions for assembly and operation, ensuring that it is ready for installation upon arrival.

Why Choose Us?

Expertise and Experience: With years of experience in manufacturing high-performance machinery, we are a trusted supplier of fiber strapping production lines and other packaging solutions.

Customization: We offer tailored solutions to meet the specific needs of your business, including customizable machine specifications and output capabilities.

Quality Assurance: Our products undergo rigorous testing to meet industry standards, ensuring durability and reliability.

Customer Focused: We prioritize customer satisfaction, offering comprehensive support and a commitment to providing high-quality machinery at competitive prices.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province