Overview

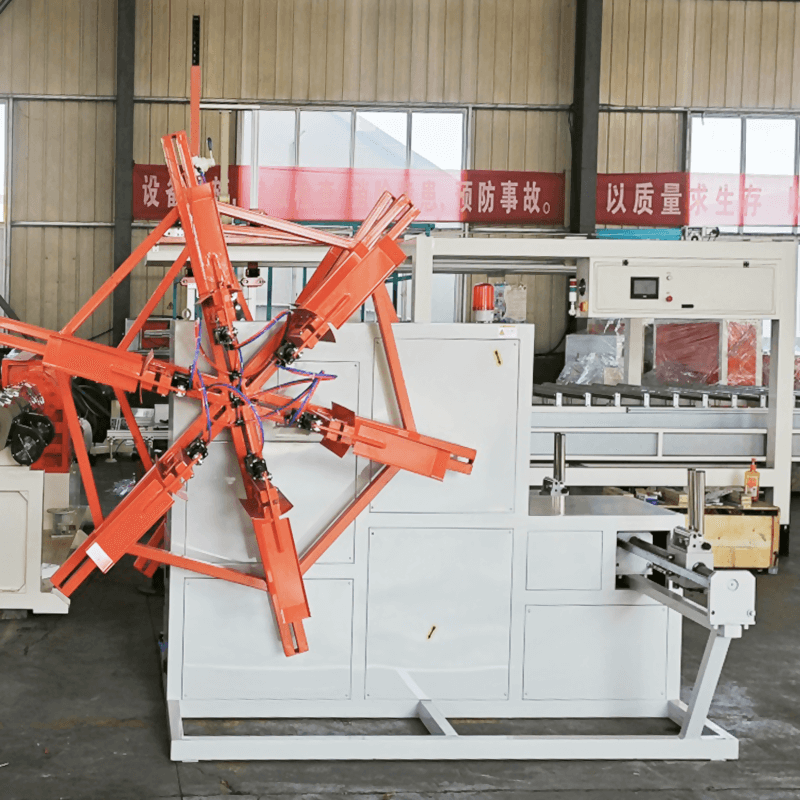

Qingdao Zhongrui Plastic Machinery’s Advanced Drainage Board Production Line is a game-changer in the plastic extrusion industry, engineered to manufacture high-performance drainage boards for construction, agriculture, and landscaping. Equipped with a precision single-screw extruder and energy-saving features, this production line balances continuous high output with consistent quality, making it the top choice for businesses seeking reliable, customizable drainage board manufacturing equipment. Whether you need solutions for foundation drainage, agricultural irrigation, or roadway construction, our line adapts to your unique project needs. Inquire today for a tailored quote!

![Plastic Pipe Production Line (2) Plastic Pipe Production Line (2)]()

Key Features & Benefits

Adjustable Thickness & Density for Versatile Applications

Our Advanced Drainage Board Production Line offers exceptional flexibility to adjust board thickness and density, catering to diverse project requirements. From thin, lightweight boards for landscaping to heavy-duty options for roadway construction, the extruder system ensures precise customization. This versatility makes it ideal for foundation drainage, agricultural irrigation, and geotechnical engineering, eliminating the need for multiple machines to meet different demands.

High-Performance Single-Screw Extruder

At the core of the line is a single-screw extruder designed for smooth, efficient material processing. It handles a wide range of plastic materials, including PVC, HDPE, WPC, and plastic composites, producing drainage boards with superior strength and water management properties. The extruder’s robust design guarantees durability, ensuring long-lasting performance even in heavy-duty production environments, while delivering consistent quality across every batch.

Energy-Efficient & High-Capacity Operation

With a production capacity of up to 500 kg/h, our drainage board production line supports continuous large-scale manufacturing without compromising efficiency. It integrates energy-saving technologies that reduce operational costs, balancing high output with low power consumption. This makes it a cost-effective solution for businesses looking to scale production while minimizing their carbon footprint.

Integrated Water-Cooling System

The built-in water-cooling system is critical to maintaining product integrity. By cooling the boards at the optimal stage of production, it prevents defects like warping or surface imperfections, ensuring every drainage board meets industry specifications. This reliable cooling process enhances consistency, reducing waste and ensuring your products stand out in the market.

Technical Specifications

Parameter | Details |

Machine Type | Advanced Drainage Board Production Line with Extruder |

Extruder Design | Single-Screw Extruder |

Cooling System | Integrated Water-Cooling System |

Production Capacity | Up to 500 kg/h (Continuous Operation) |

Compatible Materials | PVC, HDPE, WPC, Plastic Composites |

Power Supply | 380V / 50Hz |

Industry Compliance | Meets International Construction & Agricultural Standards |

Industry Applications

Construction Industry

Ideal for foundation drainage and groundwater management, our drainage board production line manufactures durable boards that protect structures from water damage. Whether used in residential buildings or large-scale commercial projects, the boards’ high strength and water-resistance ensure long-term structural integrity.

Agricultural Projects

For agricultural irrigation and soil waterlogging prevention, our line produces tailored drainage solutions that improve crop yield. The customizable density and thickness allow for optimal water flow, keeping soil conditions balanced for healthy plant growth.

Landscaping & Geotechnical Engineering

In landscaping and slope protection projects, the Advanced Drainage Board Production Line delivers boards that stabilize soil and prevent erosion. It’s also suitable for soil stabilization in geotechnical applications, ensuring landscapes and infrastructure remain intact for years.

Environmental Projects

Aligning with sustainable development goals, our line supports eco-friendly production, making it perfect for green building and low-carbon projects. The use of recycled materials reduces environmental impact, meeting the growing demand for sustainable construction solutions.

Eco-Friendly Advantages

Our Advanced Drainage Board Production Line is designed with sustainability in mind. It supports the use of recycled plastic materials, reducing plastic waste and promoting circular economy practices. The energy-efficient extruder and optimized cooling system further minimize power consumption, lowering your carbon footprint while maintaining high production standards. For businesses prioritizing eco-friendly operations, this line is a responsible and competitive choice in the plastic extrusion equipment market.

After-Sales Support & Warranty

We stand behind the quality of our Advanced Drainage Board Production Line. Every unit comes with a 1-year warranty covering manufacturing defects and component failures. Our team of experts provides 24/7 online technical support, ensuring you receive timely assistance with setup, operation, and maintenance. We also offer customization support for packaging, logos, and machine configurations, helping you align the equipment with your brand identity.

FAQ

What materials can the production line process?

The line is compatible with PVC, HDPE, WPC, and other plastic composites, meeting the diverse needs of construction, agriculture, and environmental projects.

Can the line be customized for specific requirements?

Yes! We offer full customization for board size, thickness, density, and machine configurations to fit your unique project needs.

What after-sales support is provided?

We offer a 1-year warranty from the date of delivery and 24/7 online technical support for setup, troubleshooting, and maintenance.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province