Product Description

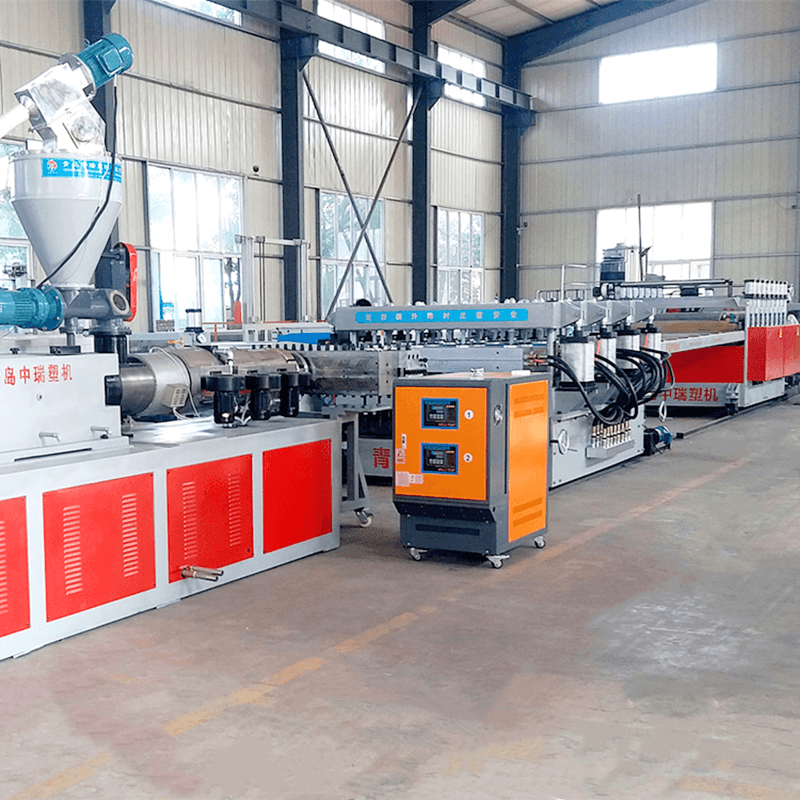

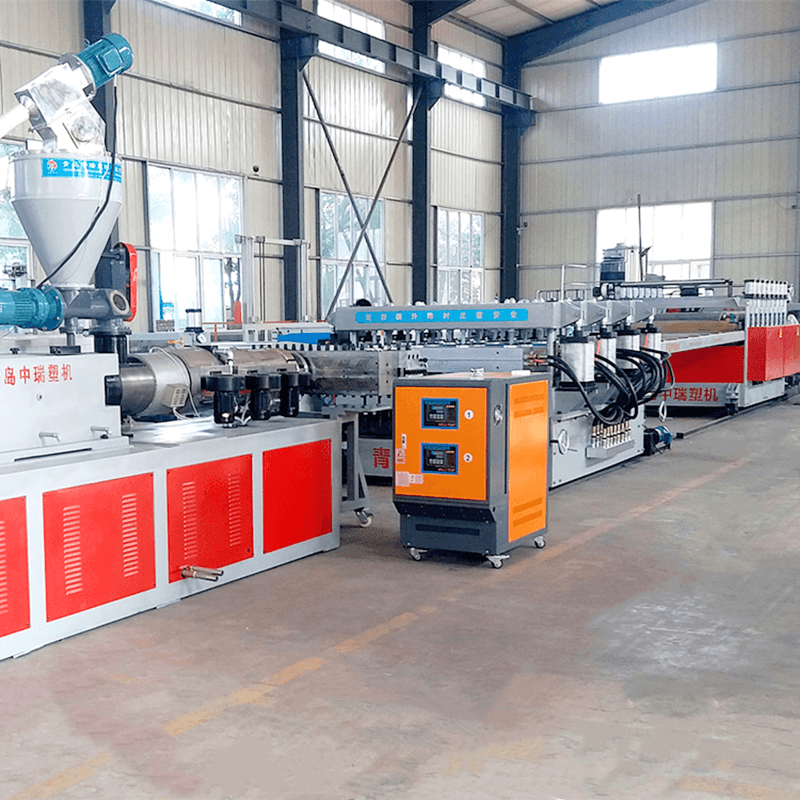

The PVC Foam Sheet Board Extrusion Machine Production Line is designed to produce high-quality PVC foam boards using advanced extrusion technology. With an automated system, this line ensures consistent output, energy efficiency, and precise temperature control throughout the production process. Key components like T-die molds, calender rollers, and an automatic stacker enhance productivity while reducing labor costs. The equipment is ideal for various industrial applications, including construction, advertising, and interior design. Its versatility and robust build make it a reliable solution for manufacturers in the plastic sheet industry.

Product Features

Efficient PVC Foam Sheet Production

The PVC Foam Sheet Board Extrusion Machine Production Line is engineered to enhance the efficiency of PVC foam board manufacturing. This system uses advanced extrusion technology to transform high-quality PVC resin into molten form, which is then shaped into continuous sheets. The sheets are rapidly cooled and cut to precision sizes, ensuring consistent product quality.

Key Components for Durability

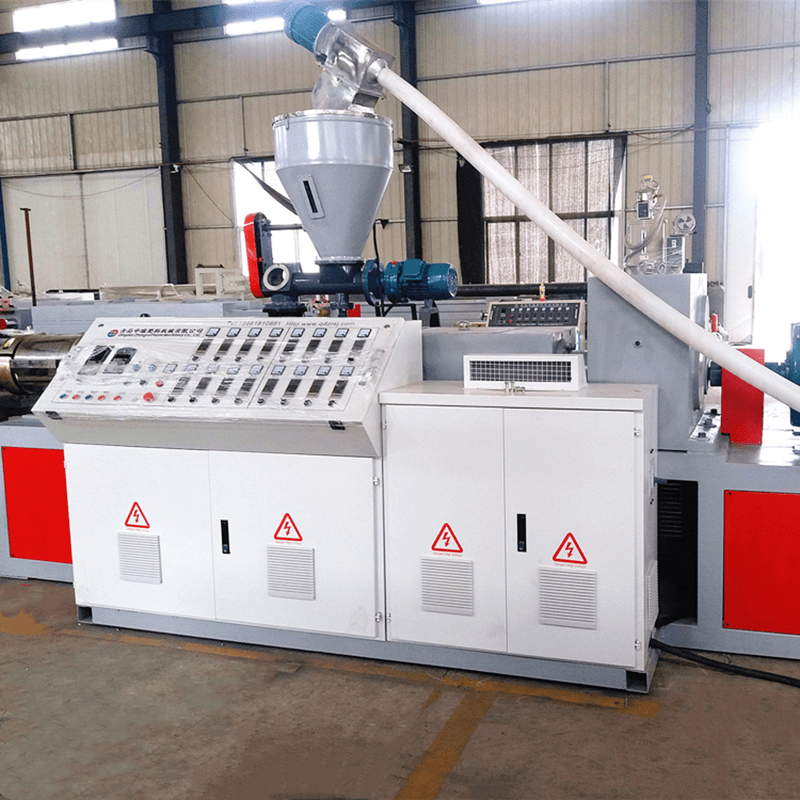

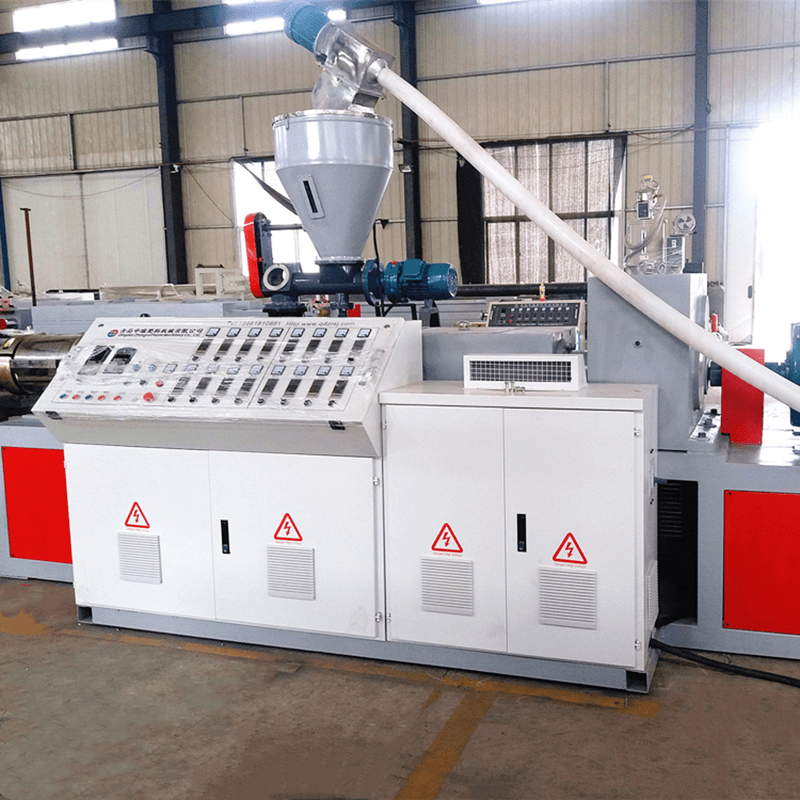

This extrusion line integrates key spare parts, including the screw, barrel, T-die molds, and calender rollers, all manufactured by Zhongrui. These components ensure the durability and reliability of the system, enabling continuous, stable production with minimal downtime. Additionally, the equipment’s precise temperature control ensures uniform plasticization, allowing for consistent output.

Automated for Enhanced Productivity

One of the standout features of this PVC foam board production line is its automation. The integration of a robotic stacker significantly reduces the need for manual intervention, minimizing labor costs while boosting operational efficiency. This allows businesses to scale production quickly, making it ideal for companies looking to meet growing market demand for PVC products.

Versatile Applications

The PVC Foam Sheet Board Extrusion Machine is designed to meet a range of industry needs, including advertising, construction, and interior design. Its ability to produce both PVC foam boards and billboards makes it a versatile addition to any plastic sheet manufacturing operation. With efficient production rates and automated systems, this equipment provides a competitive edge in the industry.

Product Features

Advanced Extrusion Technology

The PVC Foam Sheet Board Extrusion Machine Production Line uses advanced extrusion technology to melt and shape PVC materials efficiently. It ensures a consistent melt flow, improving the quality of the foam sheets and providing reliable results in both high and low production environments.

Key Spare Parts for Durability

Our PVC Foam Sheet Board Extrusion Machine Production Line includes durable screws, heat-resistant barrels, precision T-die molds, and calender rollers. These parts are built for long-lasting performance, reducing maintenance needs and enhancing the reliability of the production line.

Fully Automated System

The automated system of the PVC Foam Sheet Board Extrusion Machine Production Line includes an automatic robotic stacker that minimizes manual labor, increases productivity, and reduces errors. The system operates smoothly with minimal intervention, ensuring consistent product quality.

Energy-Efficient Design

This PVC Foam Sheet Board Extrusion Machine Production Line is designed to consume minimal energy while maintaining high production efficiency. Features like high-efficiency motors help reduce electricity costs, making the system cost-effective for large-scale production.

Wide Application

Our PVC Foam Sheet Board Extrusion Machine Production Line is perfect for producing PVC foam boards for various industries, including advertising, construction, and interior design. It’s suitable for creating foam sheets used in signage, partition panels, and thermal insulation materials.

Cost-Effective Production

The PVC Foam Sheet Board Extrusion Machine Production Line helps reduce production costs by offering high output and efficient use of materials. It produces consistent, high-quality foam boards at a lower cost, making it an ideal investment for businesses looking to improve profitability.

How to Use

Load high-quality PVC resin into the extruder.

Adjust the temperature and extrusion settings according to production requirements.

Start the extrusion process to melt and shape the PVC material.

Monitor the automatic cooling and cutting processes.

Utilize the robotic stacker to collect finished sheets efficiently.

Perform regular maintenance checks to ensure continued productivity.

| PAR T1 THIS LINE CONSISTS OF (COMPULSORY) |

| 1 | Automatic spring feeding machine | 1 set |

| 2 | Conical twin screw extruder | 1 set |

| 3 | T-type /hanger type die head (JC-Times brand) | 1 set |

| 4 | Three Roller Calendars | 1 set |

| 5 | Rollers thermoforming machine | 1 set |

| 6 | Cooling frame and edge cutting unit | 1 set |

| 7 | Haul off machine | 1 set |

| 8 | Plastic cutting machine-Guillotine | 1 set |

| 9 | Twin position winder | 1 set |

| 10 | Spare parts | 1 set |

|

| PART 2 ACCESSORY MACHINE PARTS (OPTIONAL) |

| 11 | High speed hot and cold mixer | 1 set |

| 12 | Plastic crusher | 1 set |

| 13 | Plastic pulverizer | 1 set |

| 14 | Air compressor | 1 set |

| 15 | Industrial water chiller | 1 set |

|

| PART 3 SHEET SPECIFICATIONS |

| 1 | Sheet width | 1220mm, 1560mm, 2050mm |

| 2 | Sheet thickness | 1-10mm |

| 3 | Type | Rigid pvc, free foam |

|

| PART 4 SHEET APPLICATIONS |

| 1 | advertisements decoration, screen printing, computer lettering, advertising signs, exhibition board, sign board, electronic instruments packing etc. |

Application range of PVC foam board

Industrial applications: | anti-corrosion projects in the chemical industry, thermoformed parts, plates for cold storage, special cold preservation projects, and plates for environmental protection. |

Transportation industry: | ships, airplanes, passenger cars, train carriages, roofs, core layers of carriages, interior decoration panels. |

Construction and decoration industry: | building exterior wall panels, interior decoration panels, residential buildings, offices, public places, building partitions, commercial decorative frames, clean room panels, ceiling panels, kitchenware, and sanitary ware. |

Advertising industry: | Screen printing, computer lettering, advertising signboards, signboards. |

Other uses: | templates, sports equipment, aquaculture materials, seaside moisture-proof facilities, water-resistant materials, art materials, various lightweight partitions. |

FAQ

Q1: What types of PVC products can this machine produce?

A1: This machine is designed to produce PVC foam boards, billboards, and other plastic sheet products.

Q2: What is the maximum output capacity of the extrusion line?

A2: The production line can produce up to 450 sheets per day, depending on thickness and other variables.

Q3: Is the system easy to operate?

A3: Yes, the machine features an automated process with user-friendly controls, making it simple to operate and maintain.

Service and Support

1. Pre-Sales Consultation

Product Customization: Our team provides detailed consultation services to help you customize the machine based on your production needs. From material selection to production capacity, we guide you through the decision-making process.

Technical Support: We offer expert advice on how to optimize your production line for maximum efficiency and output.

Machine Demonstrations: If needed, we can provide machine demonstrations and samples to help you understand the machine’s capabilities before making a purchase.

2. Installation and Training

Online Installation Support: Our expert technicians will guide you through the installation process via video calls and online tutorials, ensuring the machine is set up correctly and runs smoothly.

Training for Operators: We offer comprehensive training for your staff on how to operate the machine, maintain it, and troubleshoot minor issues. This training ensures your team can run the machine efficiently and safely.

On-Site Installation (Optional): For large-scale orders, we can send technicians to your facility to oversee the installation and provide hands-on training.

3. Ongoing Technical Support

24/7 Online Assistance: Our dedicated technical support team is available 24/7 to help with any issues or questions you may have. You can reach us through email, phone, or online chat.

Troubleshooting: If any issues arise during the machine’s operation, we provide troubleshooting steps and solutions to minimize downtime.

Software and Firmware Updates: We keep our clients updated with the latest software and firmware to ensure their machines operate at peak performance.

4. Maintenance and Spare Parts

Spare Parts Availability: We stock all the essential spare parts for the PVC Foam Sheet Board Extrusion Machine. These parts are readily available for fast delivery.

Preventive Maintenance: Regular maintenance ensures the longevity of the machine and prevents breakdowns. We provide comprehensive maintenance guides and can also offer periodic maintenance services.

Warranty Service: The machine comes with a one-year warranty. During this period, we provide free replacement parts and repairs if any defects arise due to manufacturing issues.

5. After-Sales Feedback

Customer Satisfaction Surveys: We regularly conduct surveys to collect feedback on product performance and service quality. Your feedback helps us improve our products and services.

Continuous Improvement: We value your input and continuously work to enhance our offerings based on the feedback received from our customers.

6. Global Delivery and Logistics Support

Shipping and Delivery: We offer reliable and fast shipping services globally. Our logistics team ensures timely delivery of the machine to your location, minimizing delays.

Tracking and Support: Once your order is dispatched, we provide tracking details, and our team is available to address any shipping concerns during the transit.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province