Overview

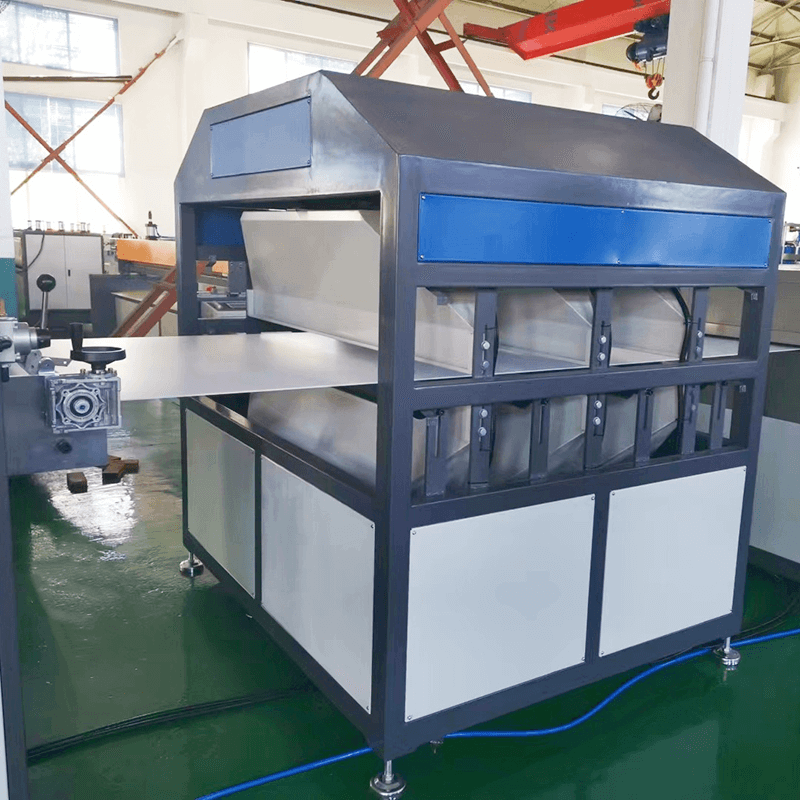

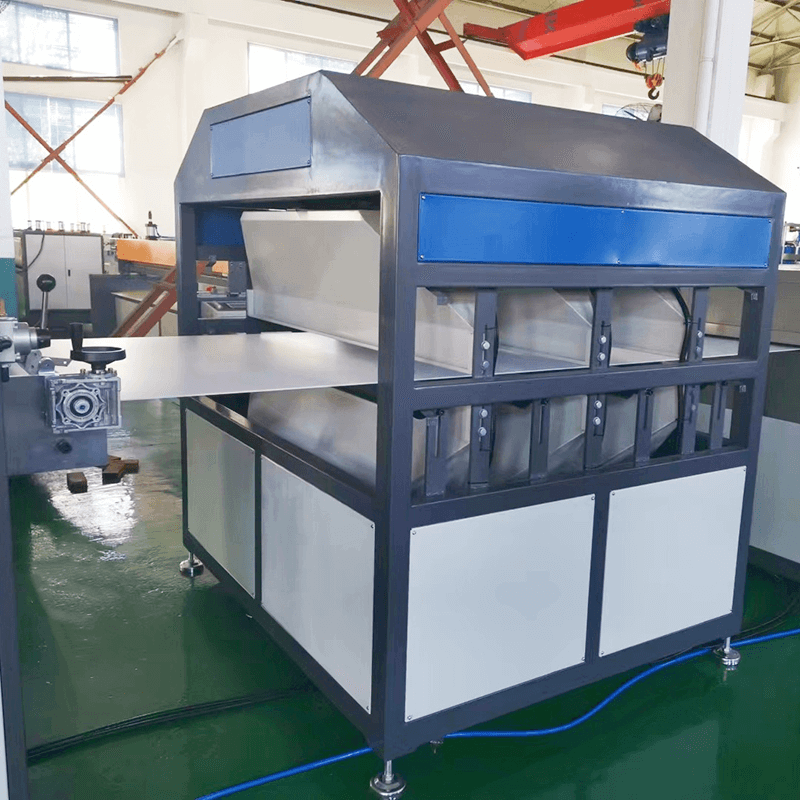

Our PP Hollow Grid Board Production Line is a specialized manufacturing solution designed to produce high - quality polypropylene hollow grid boards. These boards are highly valued for their lightweight, high strength - to - weight ratio, excellent impact resistance, and good chemical resistance. The production line integrates a series of advanced processes, including material mixing, extrusion, shaping, cooling, and cutting, to create hollow grid boards with consistent quality and performance. Controlled by an intelligent automation system, it ensures a smooth and efficient production process, enabling manufacturers to meet the diverse needs of various industries for packaging, construction, and other applications.

Features

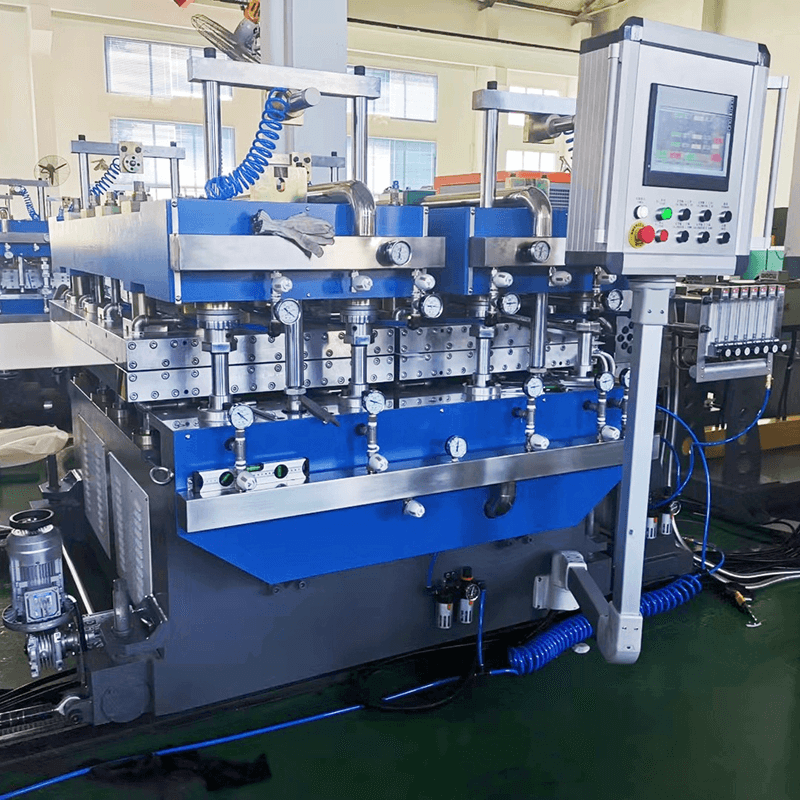

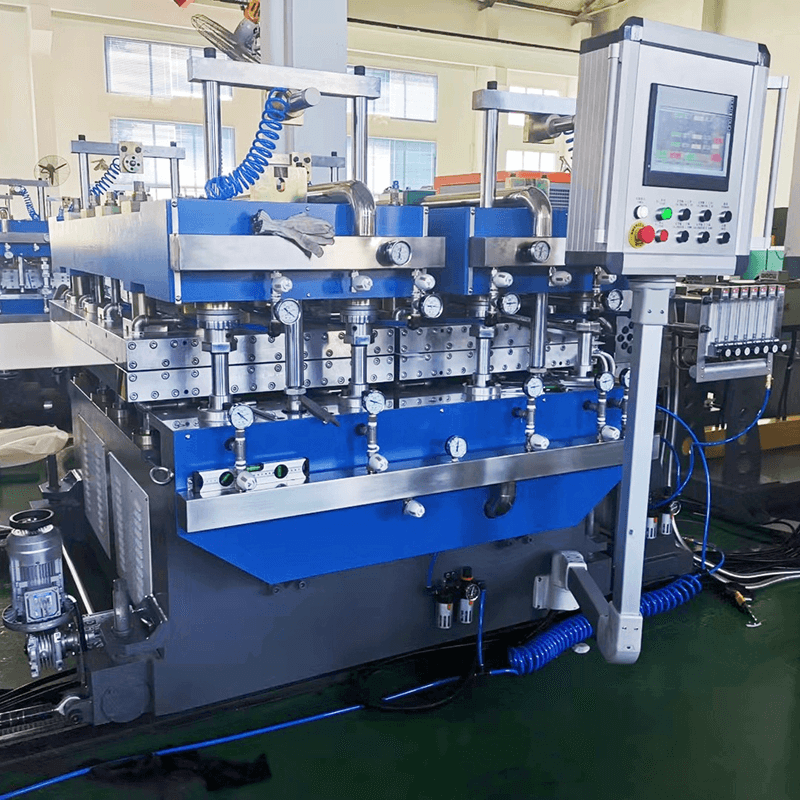

• Unique Extrusion and Molding Process: The production line features a unique extrusion and molding process specifically designed for PP hollow grid boards. A specialized extruder with a multi - layer die head is used to produce the hollow grid structure. The extruder precisely controls the melting and extrusion of PP resin, ensuring uniform material distribution within the board. The molding process uses custom - designed molds to shape the extruded material into the desired grid pattern, with precise control over the cell size, wall thickness, and overall board dimensions.

• High - Strength and Lightweight Design: Our PP hollow grid boards are designed to have a high strength - to - weight ratio. The unique grid structure provides excellent load - bearing capacity while keeping the board lightweight. This makes the boards ideal for applications where weight reduction is crucial without sacrificing strength, such as in packaging and construction. The use of high - quality PP resin also ensures the boards have good impact resistance and chemical resistance, enhancing their durability and lifespan.

• Automated Production and Quality Control: The production line is highly automated, reducing manual labor and minimizing human errors. A programmable logic controller (PLC) system coordinates the entire production process, automatically adjusting parameters such as extrusion speed, temperature, and cutting length. Online sensors continuously monitor the quality of the boards during production, detecting any defects in surface quality, dimensions, or structural integrity. Defective boards are automatically rejected, ensuring that only high - quality products are delivered to customers.

Applications

• Packaging Industry: In the packaging industry, PP hollow grid boards are widely used for manufacturing boxes, trays, and pallets. Their lightweight nature reduces shipping costs, while their high strength ensures the protection of packaged goods during transportation and handling. The boards' excellent chemical resistance also makes them suitable for packaging products that may come into contact with chemicals or moisture, such as electronics, food, and pharmaceuticals.

• Construction and Decoration: In the construction and decoration sectors, PP hollow grid boards can be used for various applications, such as wall panels, ceiling tiles, and partition boards. Their lightweight and easy - installation features make them a popular choice for interior decoration projects, reducing construction time and costs. The boards' good insulation properties also contribute to energy savings in buildings, making them an environmentally friendly option for construction.

• Agriculture and Horticulture: In agriculture and horticulture, PP hollow grid boards are used for manufacturing greenhouse panels, seedling trays, and storage containers. Their resistance to UV rays, moisture, and chemicals ensures long - term use in outdoor environments. The boards' lightweight and durable design also make them easy to handle and transport, facilitating agricultural and horticultural operations.

![PP Hollow Grid Board Production Line PP Hollow Grid Board Production Line]()

Advantages

Efficient Production: Reduces labor costs with fully automated processes, increasing overall production efficiency.

Customization: Can be adapted for different board types, including PP, PE, and PC, providing versatility for various industries.

Energy-Efficient: Designed to minimize energy consumption while maximizing output.

High Durability: Built to last with robust materials that can handle long-term production without frequent breakdowns.

Comprehensive Support: Online technical support and a one-year warranty ensure peace of mind for customers.

Why Choose Us?

Experienced Manufacturer: With years of expertise in the extrusion machinery industry, Zhongrui Machinery is committed to providing high-quality, reliable solutions.

Customization: We offer fully customizable production lines to meet your specific needs.

Support: Our customer service includes online technical support, installation assistance, and training to ensure smooth operation.

Quality Assurance: We adhere to strict quality control standards and offer a one-year warranty for all machines.

Packaging

The Hollow Grid Board Production Line is carefully packaged to ensure safe delivery. It is typically packed in a wooden case or metal frame, depending on the customer’s requirements. All necessary accessories and documentation are included in the packaging.

FAQ

What materials can be used with this machine?

This production line is compatible with various materials including PP, PE, and PC, allowing for versatile production.

What is the warranty on the equipment?

Can the machine be customized for specific production needs?

Yes, we offer customization options to adjust the thickness, width, and material specifications based on your production requirements.

How long does it take for delivery?

Do you provide after-sales support?

Yes, we offer online technical support, installation guidance, and troubleshooting assistance for all our customers.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province