Ⅰ. Product introduction

Basic Info.

| Model NO. | SJWQG-Z45*28 | Screw No. | Double-screw |

| Automation | Automatic | Computerized | Computerized |

| Customized | Customized | Condition | New |

| After-sales Service | Lifetime Service, Lifetime Maintenance | Motor Power | 18.5kw |

| The Screw Rotation Speed | 5-50r/Min | Positioning Accuracy | 0.05mm |

| Screw Diameter | 45 mm | Transport Package | Container |

| Specification | 12-25mm | Trademark | zhongrui |

| Origin | Qingdao, China | Production Capacity | 100 Sets |

| Package Size | 1800.00cm * 150.00cm * 250.00cm | Package Gross Weight | 5000.000kg |

PVC fiber reinforced hose production line

Features: This unit is a special set of equipment for producing PVC fiber reinforced hoses (also known as PVC net pipes). PVC fiber reinforced hose is transparent, pressure resistant, stretch resistant, acid and alkali resistant, corrosion resistant, beautiful in appearance, soft and light, and durable. It can be widely used in food and sanitation industries. It is a good pipeline for air, oil and other liquids and gases in the range of -5 degrees to 65 degrees.

The PVC fiber reinforced hose production line is a new product developed by our company, which is mainly used to produce PVC fiber reinforced hoses for fluid transportation. The hose has many characteristics such as non-toxic, transparent, pressure resistant, stretch resistant, acid and alkali resistant, beautiful appearance, soft and light, durable and can be widely used in air, water, gas, oil and other liquid and gas Conveying pipeline.

The PVC fiber reinforced hose production line is mainly composed of extruder spray water tank, tractor, threading machine, coiling machine and so on. It has the characteristics of reasonable matching, unique structure, reliable performance, simple operation, convenient maintenance, and strong continuous production capacity. It is deeply welcomed and trusted by users.

![PVC fiber reinforce hose production line]()

Technical Parameters

Model | SJ45/30

| SJ65/30 |

| PVC Hose Diameter range(mm) | 6-16mm | 12-50mm |

| Capacity(kg/h) | 20-40 | 40-80 |

| Installed power (kw) | 35 | 50 |

| Operator | 1-2 persons per shift

|

| Material of Hose | PVC Granules + Polyester thread |

Ⅱ. Application & Features:

1.This production line is specifically engineered for the manufacturing of high-performance PVC reinforced pipes, which are extensively utilized across industrial, agricultural, forestry, construction, and infrastructure applications. The pipes produced are recognized for their durability, chemical resistance, and structural strength, supporting fluid and gas transport in diverse environments—from irrigation networks and greenhouse systems to building drainage and industrial piping.

2.The production line is equipped with two high-efficiency single-screw extruders, ensuring stable melt processing and uniform material distribution. It integrates a precision yarn braiding machine that reinforces the pipe structure with consistent braid angles and tension control, along with essential auxiliary units such as cooling tanks, haul-off systems, cutting devices, and winding stations—forming a seamless, automated production process from extrusion to final packaging.

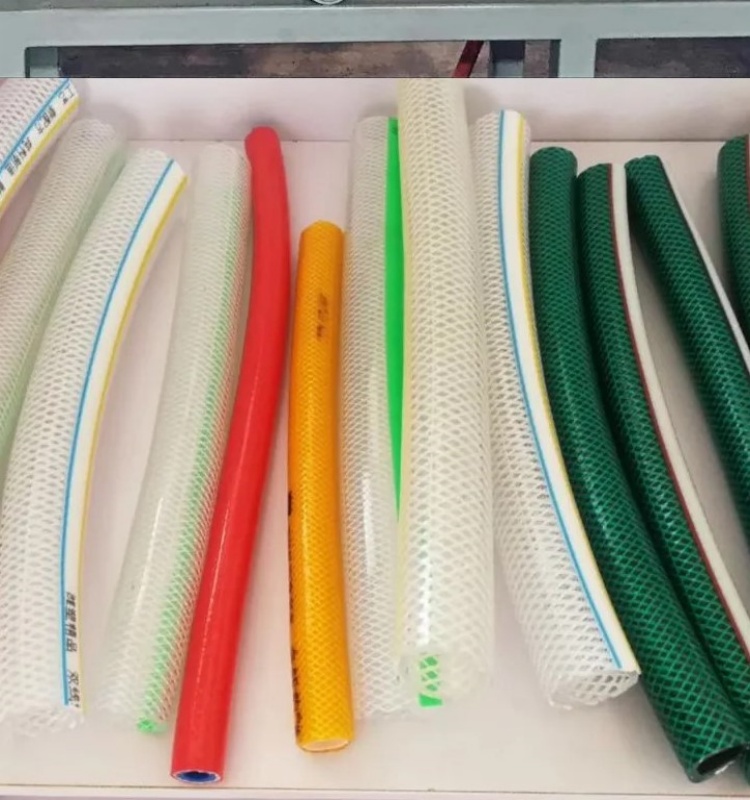

3.By utilizing interchangeable dies, the line can flexibly produce a wide range of soft pipe specifications, including various diameters, wall thicknesses, and reinforcement designs. The PVC Fiber Reinforced Flexible Pipe—commonly known as grid pipe or snake skin pipe—is designed to convey medium-pressure and corrosive fluids and gases. Its flexible yet robust structure combines internal smoothness for efficient flow with external reinforcement for pressure resilience, making it a versatile solution for demanding transport applications.

4.Today, this type of pipe is widely applied across multiple sectors such as mechanical engineering, coal mining, petroleum extraction, chemical processing, and precision agriculture irrigation. It also serves key roles in civil and residential applications, including solar water heater connections and gas canister installations. In recent years, its adoption has significantly expanded in landscaping, garden irrigation, and lawn maintenance systems, where its flexibility, ease of installation, and environmental resistance make it an ideal choice for sustainable and efficient water distribution.

![pvc reinforce hose product]()

![product]()

Ⅲ. Production process flow:

Raw material + additive→Mixed granulation→delivery → Single screw extruder →Extrusion die→Spray cooling water tank→Belt traction→Fiber winding machine→Preheat the oven→Single screw extruder→Extrusion die→Spray cooling water tank→Belt traction→Winding machine→Finished product inspection and packaging.

![Single screw plastic extruder]()

Single Screw Extruder (one inner layer pipe extruder, one coating layer pipe extruder )

There is 45/30,50/30,65/30... etc extruders according diameters and ouput.

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality sheet extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel >940, the surface of screw is chromeplated Feeding bush with water cooling system

![Inner tube head]()

Inner Layer Pipe Extrusion Die head

The die head is made by 40Cr moulds materials.

Using mica heating way

Coating layer Pipe Extrusion Die head

The die head is made by 40Cr moulds materials.

Using mica heating way

Markline extruder

It could extrusion a colorful markline/strip on pipe surface.

It is popular choosed.

![stainless steel sink]()

Pipe Water Tank(two sets)

It is adopted stainless steel materials,2500mm cooling length.

![32 spindle winding machine]()

32 spindle winding machine

It is working for fiber yarn braiding layer.

Motor:4.4kw

Control way: inverter

![PLC winder]()

winding machine

It is working for fiber yarn braiding layer.

Motor:4.4kw

Control way: inverter

1. We not only provide machines but also offer technical guide and market evaluate.

2. We will provide all the machines for the complete production according to customer's requirements.

3. We will provide complete service for factory layout and other information to help customer to build the factory.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer.

Ⅳ. FAQ

Q1.How to pay to you?

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing.

(2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 100 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province