| Parameter | Value |

| Panel Size Options | 200mm, 250mm, 300mm, 400mm, 600mm |

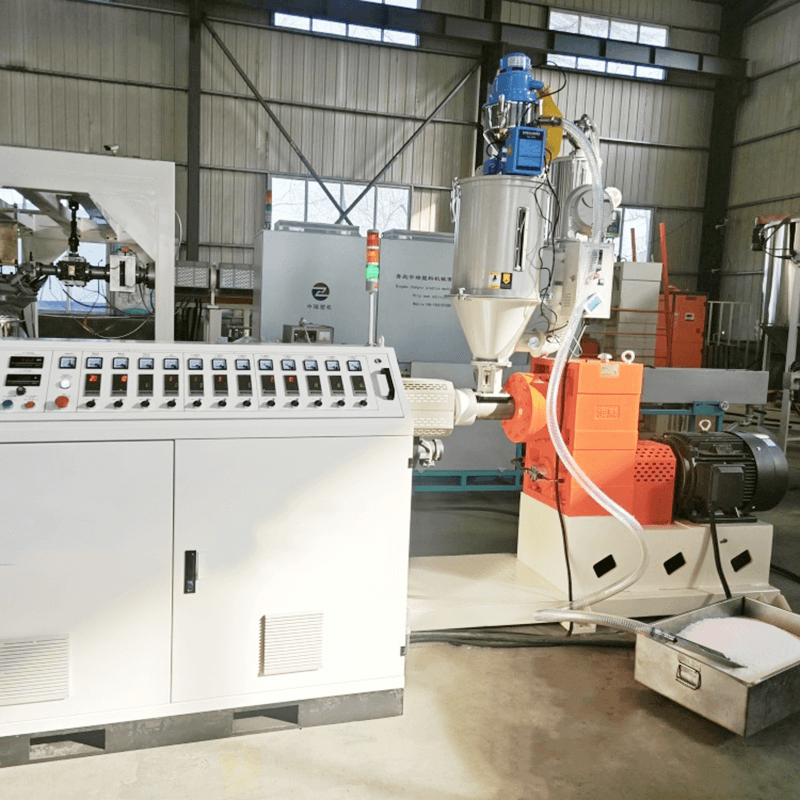

| Production Process | Material Mixing, Extrusion, Vacuum Calibration, Cooling, Traction, Cutting |

| Automation | High Automation, Easy Operation |

| Application | PVC Ceiling Panels |

| Cooling System | Water-Circulation Cooling |

| Stability | Reliable and Stable Operation |

| Main Components | Extruder, Cutter, Vacuum Calibrator |

| Machine Power | Customizable |

| Production Capacity | High Output Capacity |

Product Overview

The PVC Wall Panel Production Line for Ceilings is a specialized manufacturing system designed to produce lightweight, durable ceiling panels with superior aesthetic and functional properties. Tailored for suspended ceiling systems, this line combines high-precision extrusion with decorative surface treatment to create panels that meet strict building standards for fire safety, acoustics, and moisture resistance. With a production capacity of 180 kg/h and panel width range of 160–500mm, it efficiently manufactures ceiling solutions for commercial and residential buildings. The line’s automated workflow—from material mixing to stacking—requires minimal operator intervention, ensuring consistent quality and reduced labor costs for manufacturers.

Product Features

Acoustic Performance Optimization

Specialized foam core formulation and micro-perforation options (0.5mm diameter holes) achieve noise reduction coefficients (NRC) of 0.6–0.8, suitable for sound-sensitive environments like offices and classrooms.

Lightweight Structural Design

Using advanced foaming technology, the line produces panels with a density of 0.6–0.8 g/cm³, 40% lighter than solid PVC panels while maintaining flexural strength of 12 MPa.

Precision Dimensional Control

A multi-zone calibration unit with vacuum sizing ensures panel straightness tolerance of ≤2mm/m, critical for seamless installation in large ceiling areas. Length accuracy is maintained within ±1mm by servo-driven cutters.

Hygienic Surface Properties

The anti-microbial coating option inhibits mold growth (ASTM G21 test) and achieves 99% stain resistance against common household contaminants, ideal for healthcare and food service facilities.

Applications

Ceiling panels produced by this line excel in:

Office Buildings: Suspended ceilings with integrated lighting and HVAC compatibility.

Educational Facilities: Classroom and auditorium ceilings requiring acoustic performance.

Healthcare Settings: Hospital wards and clinics needing moisture-resistant, easy-to-clean surfaces.

Residential Complexes: Apartment and condominium ceiling systems with decorative finishes.

FAQ

What is the maximum panel length achievable?

The line produces standard lengths of 2.44m and 2.8m, with custom lengths up to 6m available through program adjustments.

Can panels be installed in humid environments?

Yes, panels have a water absorption rate <0.1% and pass 500-hour humidity testing (95% RH at 40°C) without deformation.

What surface finishes are available?

Options include matte white, wood grain, metallic, and custom printed designs with Pantone color matching capability.

What power requirements does the line need?

The system operates on 380V/3Ph/50Hz power supply with a maximum load of 90 kW, including all auxiliary equipment.

![Plastic Pipe Production Line (1) Plastic Pipe Production Line (1)]()

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province