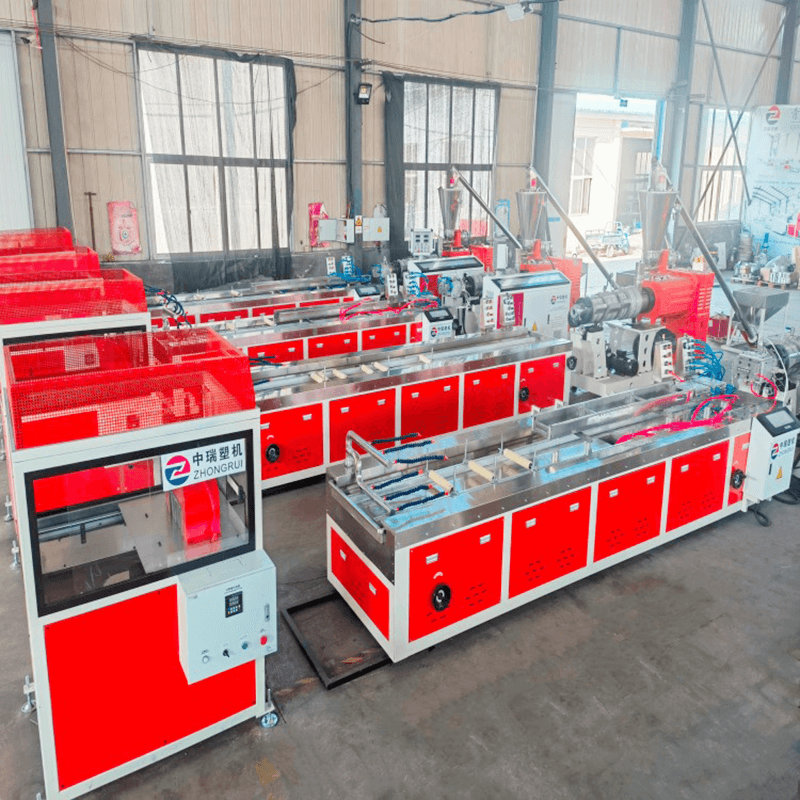

| No | Item | Quantity |

| 1 | screw feeder | 1 unit |

| 2 | SJSZ65x132 twin screw extruder | 1unit |

| 3 | Extrusion Mould | 1set |

| 4 | Calibration paltfrom | 1 unit |

| 5 | Haul-off Machine | 1 unit |

| 6 | Cutting machine | 1 unit |

| 7 | Collect platform | 1 unit |

Overview

Our PVC Wall Panel Production Line represents the latest in manufacturing innovation, offering a comprehensive solution for producing high - performance PVC wall panels. Engineered to meet the evolving demands of the construction and interior design markets, this production line focuses on efficiency, quality, and customization. From the initial selection of raw materials to the final product assembly, every step of the production process is optimized to ensure the production of wall panels that are not only visually appealing but also highly functional and durable.

Features

• Customizable Production Capability: One of the key features of our production line is its high degree of customization. Manufacturers can easily adjust various production parameters through the control system, such as panel size, thickness, color, and pattern. The line supports the production of wall panels in different lengths and widths, and the ability to change color masterbatches and decorative films allows for endless design possibilities. This flexibility enables customers to create unique wall panel solutions that meet their specific project requirements.

• Energy - Saving and Environmentally Friendly Design: We prioritize energy efficiency and environmental protection in the design of our production line. The heating system of the extruder uses advanced energy - saving technologies, such as electromagnetic induction heating, which reduces energy consumption by up to 30% compared to traditional heating methods. Additionally, the production process generates minimal waste, and the use of recyclable PVC materials aligns with sustainable manufacturing practices, making our production line an eco - friendly choice for manufacturers.

• High - Speed and High - Capacity Production: With an optimized production process and powerful machinery, our PVC Wall Panel Production Line can achieve high - speed and high - capacity production. It can produce wall panels at a rate of up to [X] linear meters per minute, depending on the panel specifications. This high - production capability allows manufacturers to fulfill large - volume orders promptly, enhancing their competitiveness in the market and meeting the growing demand for PVC wall panels.

Applications

• Retail Stores and Showrooms: In retail stores and showrooms, PVC wall panels can be used to create attractive and eye - catching displays. Their ability to showcase different colors and patterns can help highlight products and create a unique shopping atmosphere. The easy installation and maintenance of the panels also make them suitable for stores that need to frequently update their interior designs to keep up with changing trends.

• Educational Institutions: For schools, colleges, and universities, PVC wall panels offer a practical and durable solution for interior wall decoration. They can withstand the wear and tear of daily use by students and staff, and their smooth surfaces are easy to clean, promoting a hygienic learning environment. The panels' customizable designs can also be used to create inspiring and engaging spaces for students.

• Transportation Hubs: In airports, train stations, and bus terminals, PVC wall panels can be used for interior wall cladding. Their resistance to impact, moisture, and dirt makes them suitable for high - traffic public areas. The panels' fire - retardant properties, which can be enhanced during the production process, also meet the strict safety requirements of transportation hubs, ensuring the safety of passengers and staff.

![Plastic Profile Production Line (2) Plastic Profile Production Line (2)]()

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province