Overview

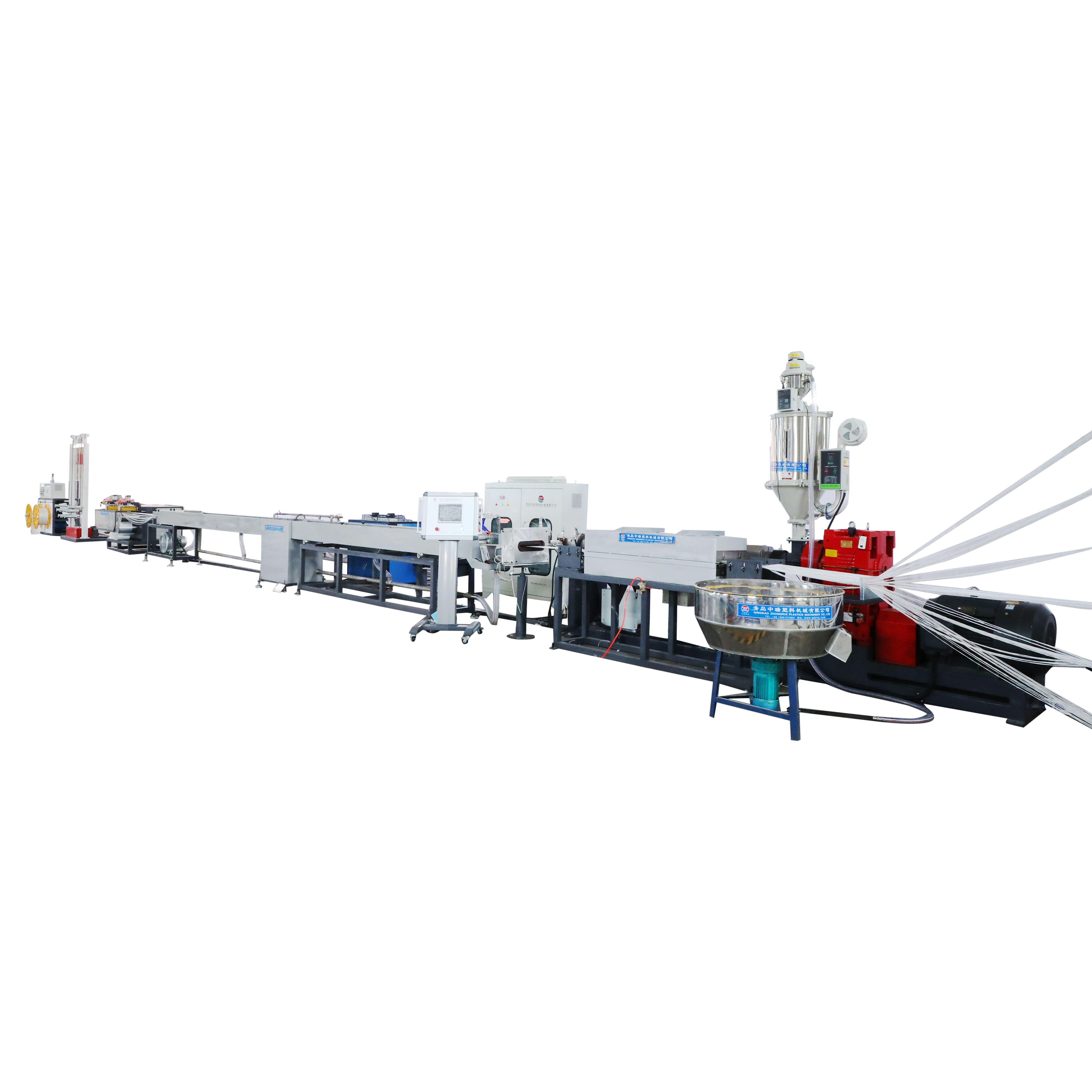

The Plastic Steel Composite Geogrid Production Line is a cutting-edge automated manufacturing system developed by Zhongrui Machinery, specialized in producing high-quality PP geogrid (polypropylene geogrid) — a new polymer composite geosynthetic material. With excellent properties including high strength, dimensional stability, corrosion resistance, and aging resistance, the produced plastic steel composite geogrid is widely applied in irrigation engineering, highways, railways, airports, coal mines, and other key engineering fields. This production line integrates precise blending, melting plasticizing, stretching, heat setting, and automatic winding, ensuring efficient and consistent production of geogrids that meet strict industry standards.

Key Features & Benefits

Exceptional Tensile Strength

The plastic steel composite geogrid produced by this line boasts ultimate tensile strength of over 20-150kN/m in both longitudinal and transverse directions, certified by quality supervision and inspection centers of the Ministry of Transport, Railway, and Water Conservancy. This high tensile strength ensures reliable reinforcement for soil structures.

Superior Dimensional Stability & Low Deformation

With a yield elongation of ≤3‰ for convex node steel-plastic geogrids, the product maintains shape even under heavy loads. The integrated production process, including precise heat setting, eliminates internal stress and reduces creep, ensuring long-term dimensional stability.

High Node Strength & Durability

Adopting fused cast convex node connection for longitudinal and transverse ribs, the geogrid features node shear strength ≥1.5MPa and ultimate peel force ≥500N. Enhanced with anti-aging and anti-oxidation additives, the geogrid has a service life of over 100 years, suitable for harsh engineering environments.

Cost-Effective & Efficient Construction

Projects using this geogrid save 10%-50% of costs compared to traditional methods. The geogrid’s width ranges from 2m-6m with fewer joints, and it can be connected via threading locks, simplifying installation, shortening construction periods, and reducing overall project costs.

Excellent Soil Reinforcement Effect

The convex node grid structure strengthens interlocking with soil and rocks, restraining lateral soil displacement, increasing foundation bearing capacity, reducing overall and uneven settlement, and preventing surface cracking.

Model NO. | 75/30 | Specification | 32-400 |

Specifications (Bandwidth Range) | 32-400 | Suitable Raw Materials | pp |

Production Line Speed | ≤160m/Min | Motor Power | 30kw |

Overall Dimensions | 25*2.5*2.5m | Screw Diameter | 75 mm |

Positioning Accuracy | 0.02mm | Maximum Extrusion Diameter | 75 mm |

Screw Speed

| 60 rpm | Screw L/D Ratio | 30:1 |

Type

| Single‑screw extruder | Barrel Heating Method | Ceramic |

Equipment Weight | 5t | Main Motor Speed

| 1480 rpm |

radeark | Zhongrui | Barrel Heating Power | 2.5 kW |

Origin | Qingdao, Shandong | Transport Package | Wooden Box |

Industry Applications

Transportation Infrastructure

Ideal for highway construction, railway engineering, and airport runways. It reinforces subgrades, resists settlement, and extends the service life of transportation facilities.

Water Conservancy Projects & Mining & Energy Projects

Widely used in irrigation engineering, river embankments, and reservoir reinforcement, thanks to its corrosion resistance and water stability.

Suitable for coal mine goaf treatment and tailings dam reinforcement, providing reliable soil stabilization in complex geological conditions.

After-Sales Support & Warranty

Comprehensive Documentation

Provide detailed service manuals, maintenance instructions for electrical components, and installation drawings (including water, electricity, and gas requirements).

1-year warranty for the entire machine (from the date of delivery) covering repair, replacement, or refund for defective products.

6-month warranty for electrical parts.

Preferential prices for spare parts after the warranty period.

FAQ

What are the payment terms?

30% of the total amount via TT as an advance payment to start production; 70% balance via TT or irrevocable L/C at sight after machine testing in our factory, followed by shipment.

What is the delivery time?

30 days for standard machines; 45 days for non-standard or customized machines (per client requirements).

Do you arrange shipment?

Yes, we arrange shipment for FOB or CIF prices.

What documents will be provided after shipment?

Original documents sent via DHL, including Packing List, Commercial Invoice, Bill of Lading (B/L), and other certificates as requested.

Is technical support available after installation?

Yes, we provide long-term technical consultation. For on-site support beyond the warranty period, additional fees may apply (negotiable).

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province