In 2025, companies see plastic extrusion machine prices from $10,000 to over $150,000. The price depends on the type of equipment and its features. The market keeps growing because more people want packaging, cars, and buildings. Customization, like in extrusion die heads, makes prices go up. Better ways to make machines help improve quality and flexibility. Companies must spend a lot on machines, buildings, and workers. This makes planning a budget very important for making money back later. Owners need to think about both starting and ongoing costs when picking plastic extrusion equipment. This helps them get good quality and use their money well.

Key Takeaways

Make a careful budget. Think about the first price and future costs of plastic extrusion machines.

Pick the right machine size and features for your needs. This helps you not spend too much and saves money.

Look at different suppliers. Ask for better prices, good warranties, and support to get the best deal.

Think about buying used or fixed-up machines to save money. Check their condition and how much energy they use before you buy.

Buy machines that use less energy. Keep them in good shape and use automation to lower costs and make more products over time.

Plastic Extrusion Machine Cost Overview

Pricing in 2025

The plastic extrusion machine market is getting bigger in 2025. 360iResearch says the global market will be about $8.06 billion. This is a 6.63% increase from last year. Plastic extruder prices are not all the same. Some single-screw machines cost around $10,000. Twin-screw or special machines can cost over $150,000. The price depends on the equipment type, how much it can make, and how much work it does by itself. Companies need to think about the first cost and the cost to keep making products. This helps them plan their money better.

Machine Type | Initial Cost | Capacity | Key Features |

Single-Screw Extruder | $10,000–$40,000 | Low–Medium | Simpler design, lower cost, basic automation |

Twin-Screw Extruder | $40,000–$150,000+ | Medium–High | Superior mixing, higher capacity, advanced controls |

Premium Customised Machines | $150,000+ | High | AI, IoT, eco-friendly modules, high capacity |

Key Cost Factors

Many things change the cost of a plastic extrusion machine. The type and size of the machine matter most. Bigger machines need more work to build and cost more. Extra features like automatic controls and energy-saving motors make machines cost more. But these features can save money later. Special parts, like custom die heads, make the price go up now and later. Rules about the environment and the price of materials also change costs. Companies should pick the right size and features for what they need. This helps them spend money wisely. The brand, help from the seller, and service after buying also change the final price. Picking the best machine helps companies save money now and in the future.

Tip: Companies that choose the right size and features for their real needs can save money and avoid spending too much.

Compare and Negotiate Pricing

Research Market Pricing

People who want to save money on plastic extrusion machines in 2025 should look up prices first. They can use market reports like the Plastic Extrusion Machinery Market Report 2025 from Cognitive Market Research. These reports give helpful facts and expert advice. They show how big the market is and how fast it is growing. The reports also break down information by machine type and use. They talk about trends in places like North America, Europe, and Asia Pacific. Buyers can ask for free sample pages or special data if they need more details. These tools help people learn about prices, new technology, and what changes costs. Talking to the people who write the reports or their sales teams can give even more details.

Use market reports to get the latest facts.

Look at trends in your area and around the world.

Ask for special data that fits your business.

Supplier Comparison

Looking at different suppliers helps control spending. Buyers should know what they need to make and what kind of machine works best. They should check how much the machine can make and how much energy it uses. It is smart to think about how easy it is to fix and keep running. Getting help after buying, like spare parts and tech support, saves money later. Buyers should also see if the supplier is trusted and known in many countries. It is important to make sure the machine meets industry rules. Buyers should also think about if the machine can handle new things like automation.

Know what you need to make and pick a machine.

Check how much the machine can make and its energy use.

Look at help after buying and if the supplier is trusted.

Make sure the machine follows industry rules.

Think about if the machine can change for the future.

Negotiation Tips

Good negotiation can help lower the total cost. Buyers should learn what the supplier is good at and plan how to talk. Being friendly with the supplier helps both sides. Buyers should show why they are valuable, like buying a lot or coming back often. They can ask for more than just a lower price, like better deals, free spare parts, or longer warranties. Buyers should watch out for hidden costs or not enough help. They should always get more than one offer and ask for videos or visits to check the machine.

Tip: Always ask for longer warranties and discounts for buying more to save money and avoid surprise costs.

Used and Refurbished Plastic Extrusion Machines

Pros and Cons

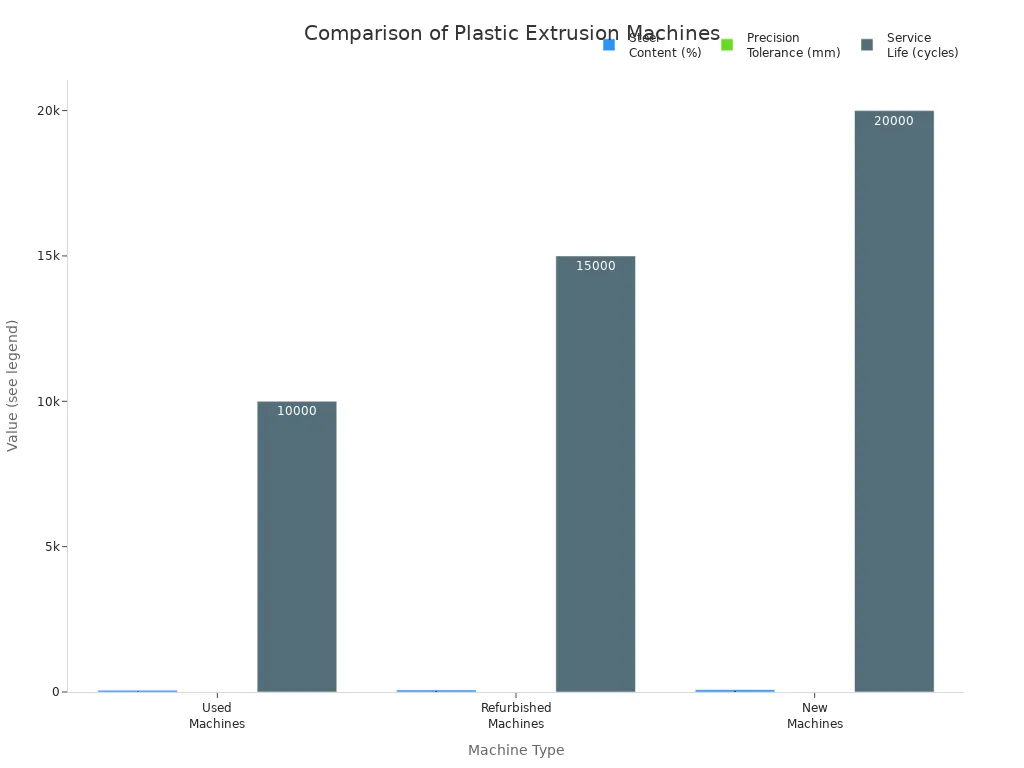

Picking used or refurbished plastic extrusion machines can help save money. Used machines usually cost less, so small businesses like them. Refurbished machines work better than used ones but still cost less than new. These machines might not last as long as new ones. They can also use more energy. You cannot change used machines much. The table below shows the main features:

Feature | Used Machines | Refurbished Machines | New Machines |

Material Composition | ~60% steel | ~70% steel | ~80% steel |

Precision Tolerance | ±0.5mm | ±0.3mm | ±0.2mm |

Customization Options | Basic | Moderate | Full |

Service Life (cycles) | 10,000 | 15,000 | 20,000 |

Energy Consumption | Higher | Moderate | Lowest |

Note: Used and refurbished machines can work well for simple jobs, but companies should think about how long they last, how much energy they use, and how exact they are.

Where to Buy

In 2025, people can buy used and refurbished plastic extrusion machines from trusted sellers. Some top brands are Vecoplan, Erema, Zerma, Herbold Meckesheim, Rapid Granulator, Cumberland, Harris, Conair, Weima, and Lindner. Many buyers use websites that show machine details, certificates, and reports about the machine’s shape. These sites help buyers pick good machines with smart tools. The U.S., Germany, and India are good places to find quality refurbished machines. Buyers should always check the seller’s reputation and what help they give after the sale.

Leading brands: Vecoplan, Erema, Zerma, Herbold Meckesheim, Rapid Granulator, Cumberland, Harris, Conair, Weima, Lindner

Global resale platforms: Give lots of details and support for new technology

Regional strengths: Germany is known for careful repairs and being eco-friendly

Inspection Checklist

Checking the machine carefully helps make sure it works well. Buyers should use a checklist to find hidden problems:

Take apart and look at all parts for damage.

Check the barrel assembly and change it if needed.

Look at the feedscrew for cracks or rough spots.

Check the gearbox, bearings, and seals.

Look at the control cabinet and update controls if needed.

Test the electrical and cooling systems to see if they work.

Check papers like service records and certificates.

Run the machine without material and make a sample to test quality.

Some common problems are cracks in the screw, film getting stuck, die build-up, and rough surfaces. Doing a test run helps make sure the machine can make good products every time.

Optimize Plastic Extrusion Cost Long-Term

Energy Efficiency

Energy-efficient machines help companies save money over time. Newer machines have special screw shapes that make more heat inside. This means they do not need as much outside heat. This can make machines use about 10% less energy. Many companies now use motors that save power and can change speed. These motors use less energy when the machine does not need to work hard. This can lower energy bills by up to 20%. Smart sensors watch how much energy is used all the time. Workers can see where energy is wasted and fix it. This can save up to 25% more energy. Adding servo motors to old machines can cut energy use by 30-50%. It also helps make products more exact. Using recycled plastic instead of new plastic can use up to 30% less energy.

Parameter | Value |

Machine Price | $20,000 |

Energy Savings Rate | 30% |

Electricity Cost | $0.10/kWh |

Machine Power Consumption | 500 kW |

Daily Operating Time | 8 hours |

Annual Operating Days | 250 days |

Electricity Cost (without savings) | $100,000/year |

Electricity Cost (with savings) | $70,000/year |

Annual Savings | $30,000/year |

Payback Period | About 8 months |

Tip: Buying energy-saving machines can pay for itself in less than a year. This is a smart way to lower plastic extrusion costs.

Maintenance Savings

Taking care of machines helps them last longer and work better. Checking screws, barrels, and gearboxes often stops big problems before they start. Cleaning and oiling parts keeps machines from breaking down. This also means less time when machines are not working. Using Computerized Maintenance Management Systems helps teams plan when to fix things. This makes machines last two or three years longer. It also stops expensive repairs. Workers who check machines every day and week keep them running well. This lowers costs and keeps products coming out the same every time.

Checking machines often stops sudden problems.

Clean and look at tools to keep products good.

Use sensors and remote checks to know when to fix things.

Automation Benefits

Automation helps companies make more products with less work. Machines that feed, cool, and cut by themselves need fewer workers. This makes things faster and saves money. Tools that check products while they are made help keep quality high. They also make less waste. Quick-change tools and full line control let one worker run many machines. This means machines are used more and do not stop as much. Automated controls help save up to 33% on energy bills. Most companies get their money back in less than two years after adding automation.

Automation Feature | Impact on Cost and Capacity |

Total Line Control | One operator manages multiple lines |

In-line Measurement | Less scrap, better quality |

Energy Optimization | Up to 33% energy savings |

Quick-change Tooling | Less downtime, higher capacity |

Note: Automation helps companies make more products, meet rules, and spend less on plastic extrusion.

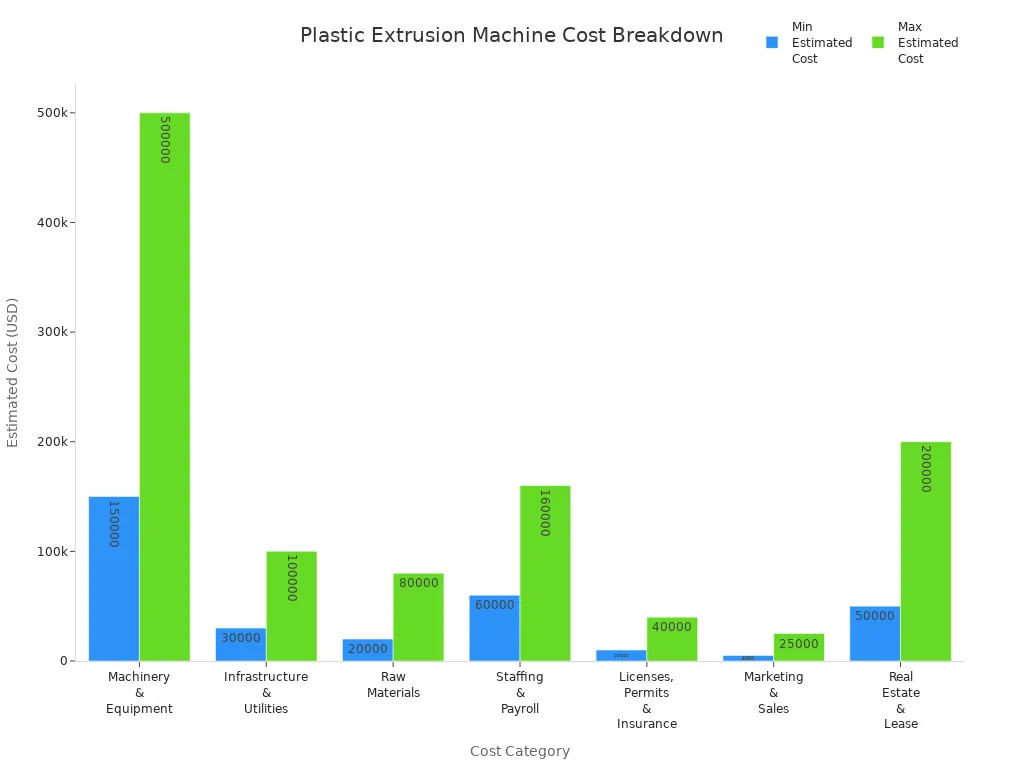

Companies can lower plastic extrusion machine costs in 2025 by buying wisely, looking at used or refurbished machines, and cutting long-term spending. Knowing about both starting and ongoing costs helps plan budgets and get more money back. The table below shows the main cost types:

Cost Type | Description | Example / Estimate |

Upfront Costs | Machine, molds, shipping, installation | $100,000 initial investment |

Maintenance Costs | Regular upkeep, 5–10% of equipment cost/year | $5,000–$10,000 per year |

Depreciation | Value loss over 5–10 years | $10,000–$20,000 per year |

Upgrades | Needed for efficiency and standards | Ongoing |

Buyers should do these things: First, decide what products they want to make and how much they can spend. Next, look at different suppliers and what each machine can do. Then, talk to experts to get advice about the machines. Last, ask for full price quotes and check what help is offered after buying.

Doing good research and making a clear budget helps companies pick the right machine and get the most value for their money.

FAQ

What is the average lifespan of a plastic extrusion machine?

Most plastic extrusion machines work for 10 to 15 years. This happens if companies take care of them. Good machines and regular care help them last longer. Companies should check their machines often. This helps stop problems before they get worse.

How often should companies service extrusion machines?

Experts say to service machines every 6 to 12 months. Regular checks help find problems early. This keeps machines working well and stops big repairs.

Can companies upgrade old extrusion machines for better efficiency?

Yes, companies can add new controls or motors to old machines. They can also add sensors. These upgrades help save energy and make better products. This can help companies spend less money over time.

What safety features should buyers look for?

Buyers should look for emergency stop buttons and safety guards. Automatic shut-off systems are important too. These features keep workers safe and stop accidents.

Are there financing options for buying extrusion machines?

Many suppliers let companies pay over time. They offer payment plans or leasing. These options help companies manage their money and pay slowly.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province