![2PET Strapping Production Line 2PET Strapping Production Line]()

Overview

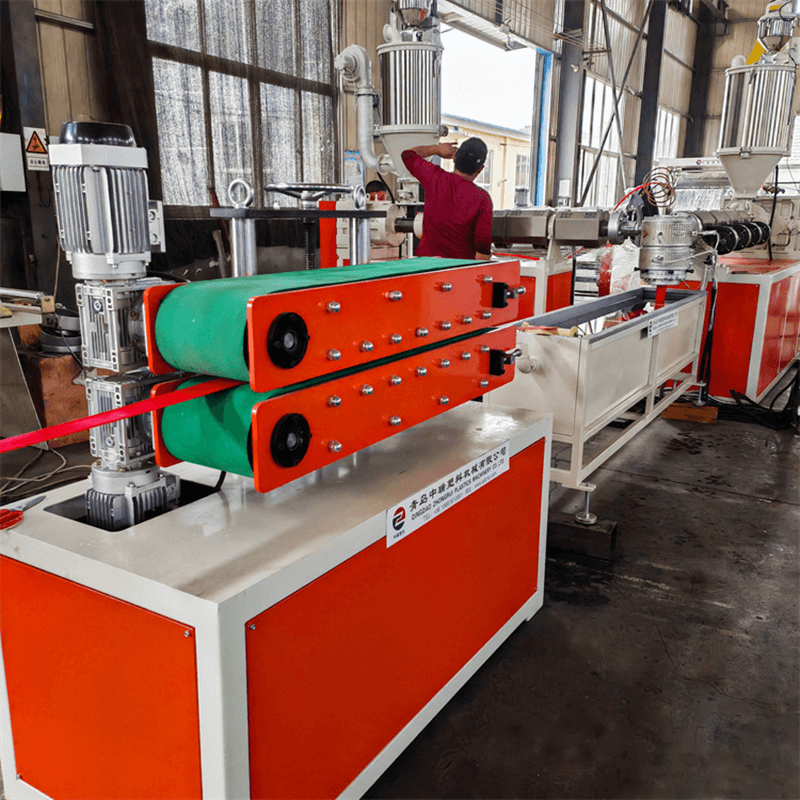

Our PET Strapping Production Line is a cutting - edge manufacturing solution designed to produce high - performance PET (polyethylene terephthalate) strapping bands. PET strapping is widely recognized for its excellent tensile strength, impact resistance, and chemical stability, making it a popular choice for heavy - duty packaging applications. This production line integrates advanced technologies and processes to ensure the production of PET strapping with consistent quality and superior performance. From the feeding of PET resin pellets to the final winding of the strapping rolls, every step of the production process is precisely controlled by an intelligent system, enabling efficient and reliable production.

Features

• Advanced Twin - Screw Extrusion Technology: The production line employs advanced twin - screw extrusion technology, which provides superior mixing and melting of PET resin pellets. The twin - screw configuration ensures uniform temperature distribution and efficient plasticization, resulting in a homogeneous melt. This, in turn, leads to the production of PET strapping with consistent physical properties, such as tensile strength and elongation. The extrusion system can handle different types of PET resins, including recycled PET, offering flexibility in raw material selection.

• Precision Cooling and Drawing Mechanism: After extrusion, the PET strapping undergoes a precision cooling and drawing process. The cooling system uses a combination of water - cooling and air - cooling methods to rapidly solidify the extruded strap, maintaining its shape and dimensional accuracy. The drawing process, which follows cooling, stretches the strap to enhance its tensile strength. A series of precisely controlled rollers and tensioners ensure that the drawing ratio is consistent, resulting in strapping with high strength and low elongation.

• Automated Winding and Packaging System: The production line is equipped with an automated winding and packaging system that can handle the finished PET strapping efficiently. The winding machine can wind the strapping into rolls of different sizes and weights, with adjustable tension control to ensure proper roll formation. After winding, the rolls are automatically packaged with protective films or cardboard, ready for storage and shipment. This automated system reduces labor costs and improves production efficiency.

Applications

• Heavy - Duty Industrial Packaging: In industries such as construction, metalworking, and machinery manufacturing, heavy loads need to be securely strapped for transportation and storage. Our PET strapping, with its high tensile strength, can withstand the weight and movement of heavy equipment, steel pipes, and metal sheets. It provides a reliable and cost - effective alternative to traditional steel strapping, reducing the risk of damage to the packaged goods due to rust and corrosion.

• Shipping and Containerization: PET strapping is widely used in the shipping and containerization industry to secure goods inside containers. Its excellent resistance to moisture, UV radiation, and chemicals ensures that the strapping remains intact during long - distance sea and land transportation. The strapping's ability to maintain tension even in varying environmental conditions provides added security for the shipped cargo.

• Recycling and Waste Management: In the recycling and waste management sector, PET strapping is used to bundle bales of recyclable materials, such as paper, cardboard, and plastic. The strapping's durability and strength ensure that the bales remain compact and intact during transportation to recycling facilities. Its recyclability also aligns with the principles of the circular economy, making it a sustainable choice for waste management applications.

| item | value |

| Application | Sheet |

| Plastic Processed | PP, PET |

| Condition | New |

| Screw Design | Single-screw |

| Screw Material | 38CrMoALA |

| Screw diameter (mm) | 90 |

| Screw L/D Ratio | 30:1 |

| Screw Speed (rpm) | 1500rpm |

| Showroom Location | United States, Brazil, Russia, South Korea, Algeria, Uzbekistan |

| Place of Origin | China |

| Shandong |

| Brand Name | Zhongrui

|

| Voltage | 380v |

| Dimension(L*W*H) | 22m*2.5m*5m |

| Power (kW) | 250 |

| Weight | 18T |

| Certification | CE ISO9001 |

| Warranty | 1 Year |

| Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support |

| Key Selling Points | High-accuracy |

| After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location | United States, Brazil, Russia, Algeria, Uzbekistan |

| Applicable Industries | Manufacturing Plant |

| Marketing Type | Hot Product |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Warranty of core components | 1 Year |

| Core Components | Motor, Pump, Gearbox, Screw |

| Name | PET strap band machine |

| Usage | Packing |

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province