Product Overview

The Fully Automatic PVC Sealing Strip Production Line represents the state-of-the-art in manufacturing precision sealing solutions for construction,automotive, and industrial applications. This highly automated system integrates material compounding, extrusion, cooling, printing, and cutting processes to produce PVC sealing strips with exceptional dimensional stability and functional performance. Capable of producing strips with cross-sectional sizes from 3mm×3mm to 50mm×20mm at speeds up to 12 meters per minute, it delivers consistent quality across high-volume production runs. Equipped with servo-driven controls and automatic defect detection, the line minimizes operator intervention while achieving material utilization rates exceeding 97%.

Product Features

High-Precision Extrusion

A conical twin-screw extruder (SJZ45/90) with closed-loop temperature control (±0.5°C) ensures uniform melt quality, producing strips with dimensional tolerance of ±0.1mm for critical sealing applications.

Multi-Functional Surface Treatment

Integrated modules support hot stamping, laser marking, and two-color co-extrusion, allowing for logo printing, color coding, and decorative patterns with 0.1mm positioning accuracy.

Advanced Foaming Technology

Optional foam core production capability creates lightweight strips with density of 180±20 kg/m³ and Shore 00 hardness of 25±5°, achieving 30% compression set ≤6% for long-term sealing performance.

Smart Quality Control

Inline vision systems inspect surface finish and dimensional accuracy, while automatic cutting units ensure length precision of ±0.5mm for strips up to 6 meters. Defective products are automatically rejected, maintaining 99.8% first-pass yield.

Applications

Produced PVC sealing strips serve diverse industries:

Building & Construction: Door and window weatherstripping, glass edge sealing, and expansion joint fillers.

Automotive: Vehicle door seals, trunk gaskets, and interior trim sealing components.

Electronics: Dust and moisture seals for appliances, control cabinets, and display enclosures.

Furniture: Edge banding, drawer seals, and acoustic damping strips for cabinetry.

FAQ

What is the maximum production speed for complex profiles?

For strips with multi-cavity or irregular cross-sections, optimal speed is 6–8 meters per minute to maintain dimensional stability.

Can the line produce flame-retardant sealing strips?

Yes, with specialized formulations, strips achieve UL94 V0 flammability rating and low smoke emission properties for building safety compliance.

How long does material changeover take?

Quick-clean extruder barrels and tool-free die changes reduce material changeover time to 30–45 minutes between different PVC formulations.

What is the typical material waste rate?

Advanced extrusion control and precise cutting minimize waste to <2%, significantly lower than the industry average of 5–7%.

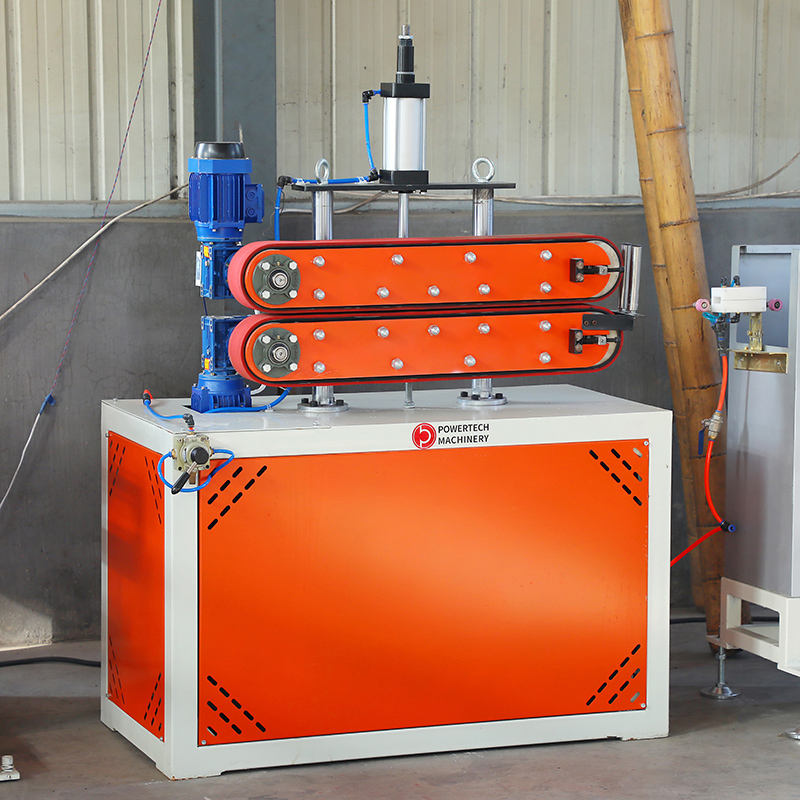

![Fully Automatic PVC Sealing Strip Production Line Fully Automatic PVC Sealing Strip Production Line]()

Main technical parameters of sealing strip extruder:

| Model of extruder | Screw Diameter(mm) | Rotating speed(r/min) | L/D | Output(kg/h) | Power(kw) | No. of barrel zone | Heating power(kw) |

| SJ45 | 45 | 12-70 | 25 | 10-35 | 7.5-11 | 3 | 5-7 |

| SJ50 | 50 | 12-65 | 20-25 | 30-50 | 11-15 | 3 | 6-8 |

| SJ65 | 65 | 10-50 | 20-25 | 50-65 | 22-37 | 3 | 7-9 |

| SJ75 | 75 | 10-50 | 20-28 | 90-120 | 45-55 | 3-4 | 8-11 |

![Fully Automatic PVC Sealing Strip Production Line 626A4585]()

![Fully Automatic PVC Sealing Strip Production Line 626A4575]()

![Fully Automatic PVC Sealing Strip Production Line 626A4573]()

![Fully Automatic PVC Sealing Strip Production Line 626A4574]()

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province