A corrugated pipe is a thin-walled cylindrical shell with transverse corrugations (similar to waves). This unique corrugated structure is the core of its function, endowing the pipe body with the ability to flexibly stretch and bend in the axial, lateral or angular directions, while maintaining sealing performance, thereby achieving multiple key functions such as medium transmission, displacement absorption, vibration isolation and measurement sensing.

I. Core Classification: Differentiated Applications of Metals and Plastics

According to the material and core application, bellows are mainly divided into two categories:

Metal bellows:

It often made of stainless steel, copper alloys, etc. Its features include resistance to high and low temperatures, high pressure, and a long fatigue life. It is commonly used as a compensator in precision instruments, valve sealing, aerospace and high-temperature and high-pressure pipelines. The "thin wall, high sensitivity..." described in the text The characteristic of "adopting auxiliary helical springs or spring plates" is precisely the typical design of some precision metal bellows used for pressure and temperature sensing.

Plastic corrugated pipes:

It mainly made of engineering plastics such as PE (polyethylene) and PA (nylon). Its features are corrosion resistance, light weight, good insulation and low cost. It is mainly used as a cable protection pipe and a fluid conveying pipe. Among them, PE corrugated pipes have become one of the most widely used plastic protective sleeves due to their excellent corrosion resistance, wear resistance, anti-aging and environmental friendliness.

![bellow product1]()

![bellow product]()

Ⅱ. The core working principle of corrugated pipes line

The core working principle of corrugated pipes lies in their utilization of the flexible deformation of elastic bodies to adapt to external changes, transmit energy or signals. When subjected to axial compressive or tensile forces, its unique corrugated structure can be compressed or stretched like a spring, effectively absorbing the thermal expansion of the pipeline or installation displacement. When subjected to lateral force or bending moment, the bellows can also undergo bending deformation like a joint to compensate for misalignment or deflection. In addition, when the internal medium pressure changes, the bellows will expand or contract accordingly. This displacement can be directly used to drive the mechanism (such as in valves) or converted into an electrical signal (such as in sensors). In conclusion, through its own controllable and reversible elastic deformation, the bellows achieves multiple key functions such as compensating displacement, isolating vibration, sealing isolation, and measurement sensing while maintaining the integrity of the seal.

Ⅲ. Application fields

Bellows, with their flexibility, sealing and protective capabilities, play an indispensable role in the following three major fields: the automotive wiring harness field.

In the field of automotive wiring harnesses

There are various types of automotive air conditioning pipe protective tubes, wiring harness corrugated tubes, flame-retardant corrugated tubes for wiring harnesses, automotive ventilation tubes, drip tubes for refrigerated transport vehicles, automotive wiring harness tubes, protective tubes for automotive braking systems, oil and gas tubes for sedans, machine tool wiring harness tubes, and other types of automotive corrugated tubes and air conditioning drip tubes.

In the field of construction engineering and decoration

Due to the characteristics of nylon corrugated pipes such as corrosion resistance, impact resistance, anti-aging, high strength, easy bending, and convenient construction, they can be widely used in the sheathed pipe systems of outdoor communication cables and optical cables, including inter-office relay pipes, electrical conduits, feeder pipes, distribution pipes, dedicated network pipes, and long-distance communication pipes as specially specified. It has strong practicality and is suitable for the laying of various cables such as wires and cables.

In the field of mechatronics

Due to the outstanding performance characteristics of nylon corrugated tubes, they are widely used in various mechanical manufacturing industries as protective tubes and wire conduits for electrical, mechanical and machine tool applications. At the same time, the reasonable combination of plastic corrugated pipes and various adapters can play a very good role in the connection between mechanical assemblies and machinery.

![In the field of automotive wiring harnesses]()

![In the field of construction engineering and decoration]()

![In the field of mechatronics]()

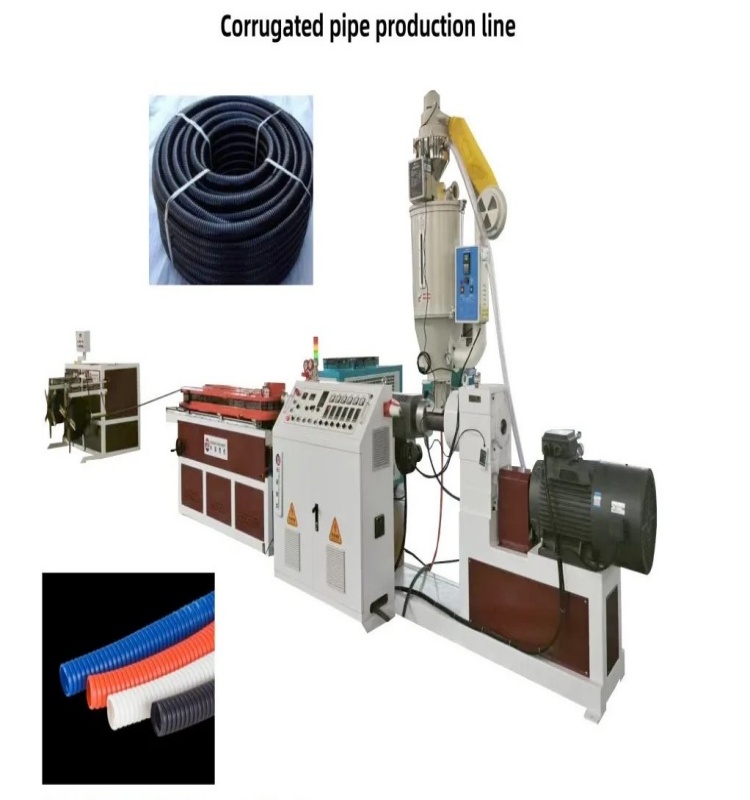

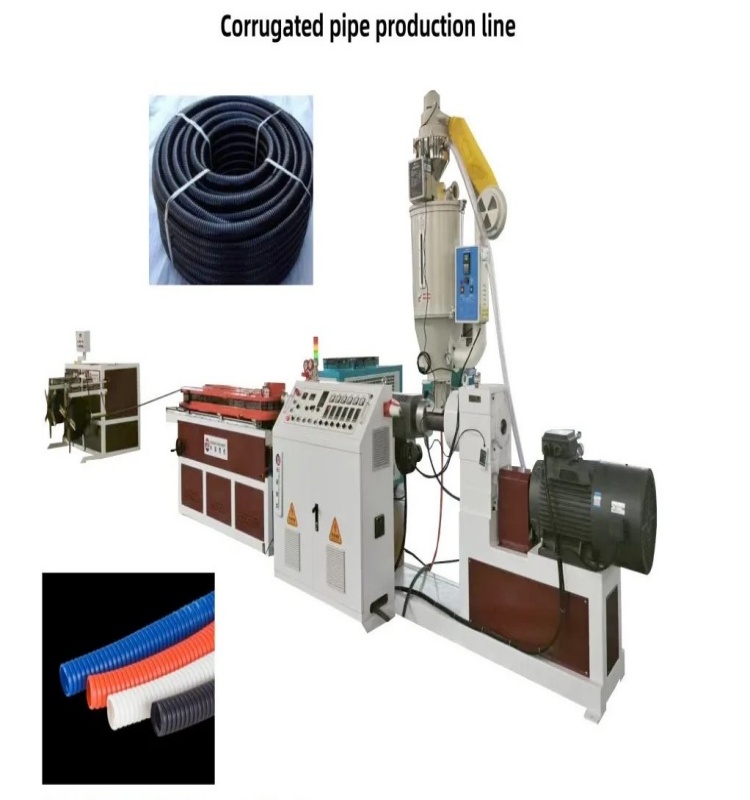

Ⅳ. Corrugated pipe production line

A typical plastic corrugated pipe production line mainly includes an extruder, forming die, cooling and shaping device, traction machine and winding machine. The core process is as follows:

![corrugated pipe production line 1]()

Raw material processing and plasticizing extrusion raw material preparation: Firstly, plastic particles such as PE or nylon (which may contain new materials and recycled materials) are sent into the hopper. At this stage, the raw materials will undergo drying treatment to remove moisture and prevent the formation of bubbles during the production process. Heating and plasticizing: The raw materials then enter the extruder. Inside the extruder, there is a high-speed rotating screw, and around it is a heating sleeve. Under the combined action of the screw's shearing and the heating sleeve, plastic particles are rapidly heated to a molten state (for PE, the temperature is usually between 180 and 220℃), and become a viscous and uniform fluid continuously extruded: the molten plastic is continuously and stably conveyed forward by the screw through a transition device called the "machine head".

![extruder and mold]()

Corrugated forming and shaping are the most crucial steps in creating a corrugated structure. Mold assembly: In front of the die head, there is a set of special forming molds. This set of molds is usually composed of dozens to hundreds of pairs of symmetrical modules on both sides. These modules form a closed ring on the track and can run continuously like a track. When each pair of modules is combined, the inner wall forms a complete corrugated shape. Air pressure forming: When the molten plastic tube blank is extruded from the die head and enters the constantly closing forming module, compressed air is precisely injected into the still soft tube blank through the guide pipe inside the die head. Under the action of air pressure, the tube blank is blown up and tightly adheres to the corrugated cavity of the cooled module

![forming machine 2]()

In some more advanced production lines, vacuum negative pressure technology is also adopted. Vacuum is drawn from the outside of the module, and the tube blank is adsorbed onto the mold by the pressure difference, ensuring that the corrugated shape is clear and full, and the forming quality is higher. The cooling and curing molding module is usually designed with cooling water channels inside, through which circulating cooling water flows. When the heat pipe blank attached to the mold comes into contact with the cold mold wall, it rapidly absorbs heat and cools down, thereby solidifying and shaping, and permanently maintaining its corrugated shape. After running on the track for one week, the module will automatically open at a specific position, detach from the formed bellows, and return to the starting point to prepare for the next cycle. This process is continuous, thus enabling the continuous production of corrugated pipes.

![Double-station winding machine]()

Continuous traction and winding: The formed corrugated pipe is clamped and pulled out at a constant speed by a crawler traction machine. The speed of the traction machine must be strictly synchronized with the extrusion speed; otherwise, it will cause the pipe to be pulled apart or deformed due to accumulation. Online control and winding: During the traction process, there will be online diameter measurement, printing and other devices. Finally, the corrugated pipes that reach the specified length are automatically wound into rolls by the winding machine, which is convenient for packaging, transportation and subsequent use.

Ⅴ. key parameters

Medium and temperature:

Metal bellows are preferred for corrosive media or high-temperature environments. PE or nylon tubes can be selected for normal temperature and weakly corrosive environments.

pressure rating:

The pressure-bearing capacity of metal corrugated pipes is much higher than that of plastic corrugated pipes.

lexibility and protection requirements:

Applications that require frequent bending should pay attention to the minimum bending radius. For outdoor use, UV resistance performance needs to be considered; for mechanical equipment, wear resistance should be paid attention to.

FAQ

Q1.How to pay to you?

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing.

(2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 100 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

![packaging1]()

![packaging2]()

![packaging3]()

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province