I. Product Overview:

Defining New Boundaries of Landscape Grass and stone isolation belts, also known as root boards or green dividers, are functional products specifically designed for modern garden design and horticultural management. It is made of high-performance polyethylene (PE), and its core function lies in precisely demarcating plant areas, regulating root growth, and clearly defining the boundaries between lawns, flower beds, and stone paths or gravel areas. Its design ingeniously combines practicality and aesthetics. It can not only enclose various smooth landscape lines through flexible shaping capabilities, but also significantly improve construction efficiency and reduce maintenance costs with a simple installation process

![grass stone isolation belt(2)]()

![grass stone isolation belt]()

II. Core Value: Multifunctional Integration, Empowering Professional Horticulture

Organization & Demarcation: They effectively divide areas for different plants and define boundaries between elements such as lawns, flower beds, and stone or gravel paths.

Prevention of Uncontrolled Growth: Made from durable polyethylene (PE) material, these barriers help control the spread of plant roots and prevent invasive species from encroaching into undesired areas.

Aesthetic Appeal: By providing clean, neat lines and edges, they enhance the overall appearance of gardens or landscape areas, making them look tidy, professional, and well-maintained. They can be bent into various shapes to accommodate creative garden designs.

Ease of Use: Designed for simple and quick installation, they save time and effort in garden planning and maintenance.

Durability: These products are known for their toughness, resistance to aging, and long service life, ensuring years of reliable performance as dividers.

III. Professional Selection Guide: Scientifically Matching Application Scenarios

In terms of material selection, HDPE is the preferred choice for long-term projects due to its excellent rigidity, weather resistance, and impact resistance. PP, although offering good stiffness, has inherent limitations in low-temperature resistance, while recycled materials are generally not recommended for critical projects due to their unstable performance and susceptibility to aging and embrittlement. The key performance requirements include exceptional weather resistance (UV resistance), adaptability to high and low temperatures, a balance of toughness and rigidity, and non-toxic, odorless environmental characteristics.

Structure and dimensions are particularly critical, as they directly impact functionality and installation convenience. Height (15-30 cm) is directly related to isolation and soil retention capabilities: 15-20 cm is suitable for shallow-rooted plants and light isolation, while 20-30 cm or taller meets the needs of deep-rooted plants and stronger soil retention. The common length of approximately 2 meters per piece strikes a balance between minimizing seams and ensuring installation flexibility. Structurally, the classic I-beam design disperses soil pressure through side wings, ensuring stable upright placement. The anchor stakes (spikes) at the bottom facilitate insertion into hard soil and enhance resistance toppling. Additionally, sturdy and easy-to-install connectors are key to ensuring smooth, integrated lines in the isolation system.

The ultimate criterion for selecting grass and stone isolation belts is the specific application scenario. For home gardens/villa landscapes, emphasis should be placed on aesthetics and flexibility, recommending medium-height (approximately 20 cm) HDPE products with good flexibility to create elegant curves. For public greenery/road slopes, durability and UV resistance are paramount, requiring taller (≥25 cm) and more rigid HDPE products to ensure long-term weather resistance. Riverbank protection/soil and water conservation scenarios demand the highest strength, necessitating structures with specifications ≥30 cm and bottom anchors to resist water erosion and achieve deep soil stabilization. In hard areas such as parking lots/plazas, products with extreme rigidity and conspicuous colors should be selected to withstand compression and clearly define green boundaries.

In modern landscaping and infrastructure development, grass and stone isolation belts have become indispensable functional materials. Their neat I-beam lines and exceptional durability are backed by a highly automated precision manufacturing process. This article will take you through a typical grass and stone isolation belt production line, step by step, revealing the entire process from plastic pellets to finished products.

IV. Precision Manufacturing Process: Technology Forging Exceptional Quality

The creation of any high-quality product begins with rigorous preparation. Before production starts, line workers load the main raw material—high-density polyethylene (HDPE) plastic pellets—into the main hopper. To produce commonly used green products, a precise metering system proportionally blends color masterbatches with the primary material.

Next, a crucial pre-treatment step—drying—commences. The raw materials are kept in a drying environment at 70–80°C for 2–4 hours to thoroughly remove absorbed moisture. If this step is neglected, the finalproduct may develop internal bubbles, significantly compromising its mechanical strength.

Simultaneously, the "heart" of the entire production line—the extruder—begins preheating. The temperatures from the feeding zone to the die are precisely set between 150°C and 210°C, creating a gradually increasing thermal gradient that prepares the plastic for melting and plasticization.

Core Stages: The Transformation from Solid to Shape

Once preparations are complete, the production line enters the core phase of continuous operation.

1. Plasticization and Extrusion

The rotating screw within the extruder barrel propels solid plastic pellets forward. Under the combined action of frictional heat and external heating, the pellets rapidly melt into a viscous, homogeneous fluid—a process known as "plasticization." This molten plastic is then steadily pushed through a specialized forming die, extruding from the die slit as a continuous parison with the same cross-sectional profile as the grass and stone isolation belt.

2.Vacuum Calibration: The Critical Moment of Shaping

The newly extruded parison remains at a high temperature and in a soft state. It immediately enters the vacuum calibration table—the most critical stage determining the product’s appearance and dimensional accuracy. The calibration table is a sealed mold whose internal contour matches the final product exactly. As the parison passes through, the vacuum pump activates, instantly extracting air through micro-pores in the mold and creating a strong negative pressure around the parison. Under atmospheric pressure, the soft parison is tightly and precisely onto the cooled mold wall, instantly forming a clear, full contour.

3. Cooling and Solidification: Locking the Permanent Shape

The preliminarily shaped parison then enters the cooling tank. Circulating cooling water, applied through spraying or immersion, rapidly reduces its temperature from the outside in, solidifying the "I-beam" structure permanently. Sufficient cooling time is essential to prevent deformation or shrinkage during subsequent handling.

4.Finishing and Precision Processing: Efficient Output through Automation

1. Synchronous Pulling and Length-Based Cutting

The fully cooled and solidified grass and stone isolation belt is gripped and steadily pulled out by a caterpillar haul-off at a constant speed. The core technology here lies in the precise synchronization of the pulling and extrusion speeds—any minor discrepancy can cause thinning or wrinkling of the product. At the end of the haul-off, the product passes through a length measurer. Once the preset length of 2 meters (or other customized lengths) is reached, a sharp cutting saw automatically activates, precisely severing the product.

2. Collection and Inspection

The cut finished products are automatically stacked via a conveyor belt or packaged by robotic arms. Throughout the production process, operators conduct continuous online inspections to ensure the products have a smooth surface, uniform color, precise dimensions, and are free of any defects

.![single screw extruder in the grass stone isolation production line]()

![Vacuum shaping platform in the grass stone production line]()

![crawler type tractor in the grass stone isolation production line]()

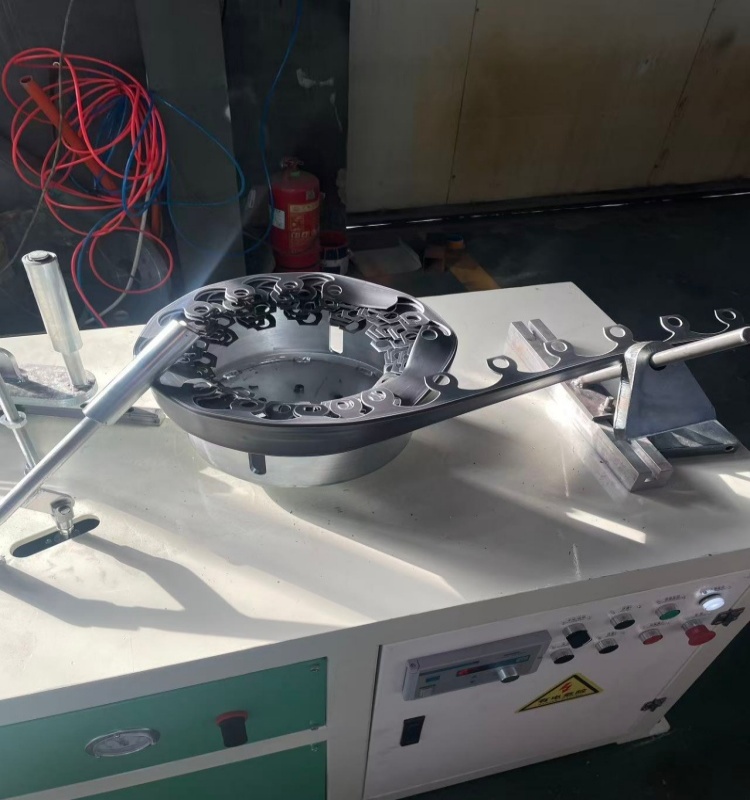

![punching machine in the grass stone isolaton production line]()

![cutting machine]()

![Single-station winding machine in the production line]()

V. A Model of Global Collaboration: The Path to Mutual Success Between Zhongrui Plastic Machinery and Belarus

As a key node in the Belt and Road Initiative and a member of the Eurasian Economic Union, Belarus has been increasingly looking East and deepening cooperation with China across various sectors, driven in part by Western policies. This has created unprecedented political and economic for the export of Chinese infrastructure materials and technologies.

Belarus serves as a transportation hub connecting the European Union and Russia, with its road and railway networks forming the lifeline of its economy. The government continues to prioritize road upgrades and modernization, such as repairing war-damaged facilities and expanding key transportation arteries. These initiatives demand large quantities of geotechnical and landscaping materials. Agriculture is also a vital component of Belarus's economy, requiring soil and water conservation solutions for farmland, pasture construction, and other projects. The government has corresponding environmental protection requirements, particularly for projects involving nature reserves and river basins, where eco-friendly solutions are highly favored.

Against this backdrop, grass and stone isolation belts have demonstrated significant application potential due to their dual functions of engineering protection and ecological restoration. They are increasingly used in scenarios such as road slope reinforcement, riverbank protection, mine re-greening, and landscape construction, with market demand entering a phase of rapid growth.

The collaboration between Belarusian clients and Zhongrui Plastic Machinery has not only fully met the local demand for high-quality grass and stone isolation belt production lines but has also delivered multifaceted benefits, achieving genuine mutual success.

For Belarus, this partnership has provided a reliable supply of high-quality production lines. Through the introduction of advanced technology and comprehensive technical support, local production capacity and product quality have been significantly enhanced, effectively supporting the country's infrastructure and ecological construction needs. Moreover, this cooperation has contributed to the upgrading of local industrial chains, created employment opportunities, and strengthened regional market competitiveness.

For Zhongrui Plastic Machinery, this collaboration has served as a critical entry point into the Eurasian market. The firsthand experience in international cooperation has provided valuable market insights and product optimization knowledge, injecting new momentum into technological innovation. Building on this opportunity, both parties are working together to establish an in-depth collaborative system covering technology research and development, production manufacturing, and market expansion. Through resource complementarity and strategic coordination, they are opening a new chapter in sustainable cooperation.

![photo with Belausian customers at the factory]()

![The Belarusian customer is testing the machine at the factory]()

VI. Application Fields and Service Commitment

The product is now widely used in three main scenarios: first, in residential landscaping, including landscape planning for home gardens, villa gardens, and community green spaces; second, in public greening, covering the construction and renovation of parks, squares, and road green belts; and third, in the leisure and tourism sector, applicable to the greening enhancement of vacation villas, tourist attractions, and other recreational environments. It provides practical and reliable grass-stone separation and landscape zoning solutions for various landscaping projects.

We offer a 1-year warranty on our high-quality machines and provide free wear-resistant spare parts for one year. If your machine breaks down or fails to operate within the warranty period and you are unable to resolve the issue, we will first attempt to identify the problem through phone calls or other communication tools based on your description. If the remote solution does not work, our engineers will visit your factory to address the issue. Additionally, they will share relevant maintenance experience with you.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province