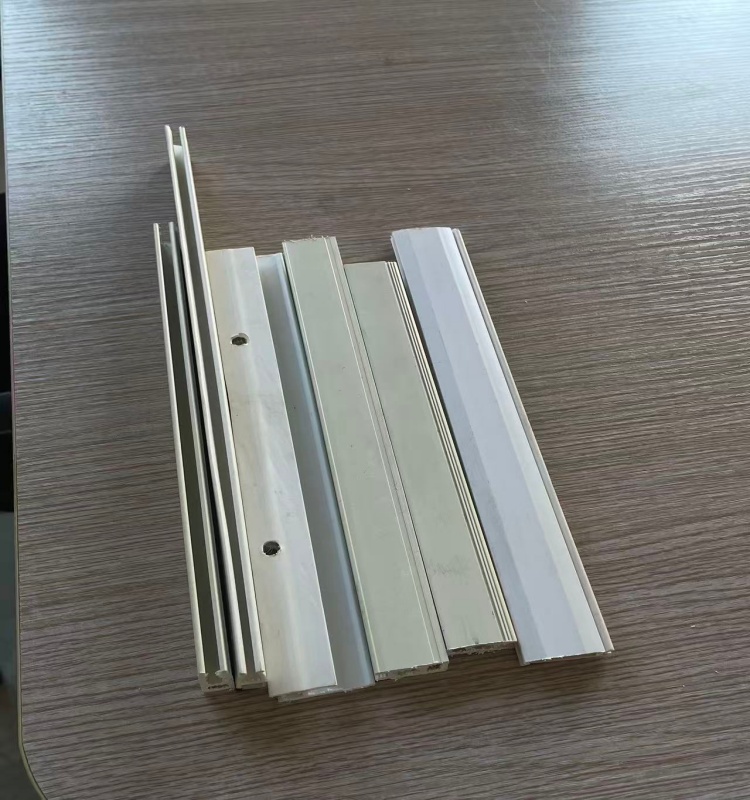

Ⅰ. The overview of The PVC ceiling strip

PVC ceiling strips are a type of polyvinyl chloride (PVC) building decoration component manufactured through extrusion molding process. Their professional name is "PVC top corner line "or "PVC decorative line", and they are often commonly referred to as "plastic gypsum line" in the industry. This product is mainly applied to the corner area where the indoor ceiling (also known as the canopy) meets the wall. Through standardized installation, it forms a continuous decorative boundary.

1. Core Function Positioning

Decorative function: Aesthetic decoration is the most intuitive core value of pvc ceiling strips. It breaks the monotony of the plane through three-dimensional modeling and greatly enhances the aesthetic level of the space. As a key decorative element connecting the ceiling and the wall, it first plays the role of a style definer - a simple flat line can enhance the freshness and neatness of modernism, while intricate European carvings or elegant Chinese circular lines can immediately set a distinct classical tone for the space. Secondly, it acts like an invisible guide for space. The smooth lines can naturally lead the line of sight, clearly outlining the contouring and structure of the room, thereby enhancing the three-dimensional effect and visual order of the space. In minimalist or large-area solid color designs, a carefully selected corner line is the finishing touch. It can infuse seemingly monotonous interfaces with rich details and a sense of refinement through delicate shapes and changes in light and shadow, highlighting extraordinary layers within simplicity.

Structural transitin function: The structural transition function is the irreplaceable practical core of pvc ceiling strips, which ingeniously solves the visual and technological problems at the junction of the ceiling and the wall. When the walls and ceilings are made of different materials (such as paint and wallpaper) or in contrasting colors, the corner lines act as a three-dimensional neutral buffer zone, which can soften and bridge the rigid color and texture gaps, making the visual transition natural and smooth, and enhancing the integrity and harmony of the space. At the same time, it is also a sophisticated "process tolerance" design, providing a perfect finishing solution for the construction handover of two different materials. It can effectively cover up the tiny gaps and flaws caused by uneven base layers, thermal expansion and contraction, or construction limitations, significantly enhancing the final completion and refinement of the decoration

Engineering shielding function: The engineering shielding function is an irreplaceable practical value of pvc ceiling strips, which can systematically solve a series of concealment needs from foundation construction to equipment installation. First of all, it is the most effective "defect repairman", capable of perfectly covering up problems such as non-vertical corners, uneven surfaces and fine cracks that are difficult to handle in the building itself or during later construction, providing an ideal visual flatness. Secondly, it is also a functional "hidden storage space". The cavity formed behind it can be used to orderly arrange lighting circuits (such as ceiling spotlights, light strips), hide air conditioning outlets, fresh air ducts or fire sprinkler heads, thus ensuring the purity and tidiness of the ceiling surface. In addition, in the detailed design, the corner lines can also ingeniously "reserve expansion joints", providing buffer space for the natural thermal expansion and contraction of the building structure, and completely hiding the resulting expansion and contraction gaps within the lines, taking into account both aesthetics and the physical characteristics of the building.

![ceiling product1]()

![ceiling product2]()

Ⅱ. Advantages of Material Properties

1. physical properties: This part of the feature is directly related to the installation experience and long-term durability of the product. The density is only 1.4-1.6g/cm³, approximately one-third of that of traditional gypsum lines. This means that each line is very lightweight, greatly reducing the labor intensity of handling and installation. It can be easily operated by a single person and also reduces the load on the building's top structure. The elongation at break is ≥200%. This extremely high value indicates that the material has excellent flexibility and impact resistance, and is not prone to brittle fracture due to bumps during handling, slight bending during installation, or accidental impacts during later residence, ensuring the safety of product transportation and its service life. The heat distortion temperature is ≥70℃, ensuring that the lines can maintain their shape stability and will not soften or deform due to heat under normal indoor temperature changes and even in some areas (such as the window side exposed to direct sunlight) where higher ambient temperatures may occur.

2.Weather resistance: This is the key to measuring whether the product can adapt to complex environments, especially damp and light conditions. A water absorption rate of less than 0.1% is an extremely low value, almost non-absorbent. This fundamentally eliminates problems such as expansion, deformation, and mold caused by moisture absorption, giving it a natural advantage in applications in high-humidity Spaces like bathrooms, kitchens, and basements. The dimensional change rate is less than 0.2% in a 95% humidity environment, further confirming its outstanding dimensional stability and ensuring that it will not crack or warp due to seasonal or regional humidity changes after installation. After modification, it can withstand over 1000 hours of QUV aging tests. QUV tests are accelerated aging experiments that simulate long-term ultraviolet radiation. Passing this test means that the product can maintain the stability of color and material for a long time even in areas with ultraviolet radiation such as near Windows and sunrooms, without yellowing or powdering, and its durability far exceeds that of ordinary materials.

3. safety performance: This part concerns the fundamental safety, health and environmental protection of the architectural space. The oxygen index is ≥32% and reaches the V-0 flame retardant grade. The higher the oxygen index, the less flammable the material is. V-0 is one of the highest flame retardant grades in the UL94 standard, meaning that the material can self-extinguish within an extremely short time (within 10 seconds) after coming into contact with an open flame, without generating burning droplets (to avoid igniting other items). This wins precious time for escape and firefighting in the event of a fire and is an important passive fire safety guarantee. The heavy metal content complies with the EU RoHS Directive, indicating that the product strictly limits the use of harmful heavy metals such as lead, mercury and cadmium from the source of raw materials, ensuring its environmental friendliness and healthiness as an interior decoration material. The toxicity index of combustion flue gas meets the standard, which means that even in the extreme case of incomplete combustion, the toxicity of the flue gas produced is controlled within a safe range. This can minimize secondary injuries caused by toxic flue gas in fires to the greatest extent, providing a double guarantee for life safety.

Ⅲ. The PVC ceiling production line

The PVC ceiling strip precision extrusion production line is a highly integrated continuous production system. Its process flow begins with the precise automatic batching and high-speed thermal mixing of PVC resin with calcium carbonate fillers, stabilizers and other auxiliary materials. The mixed materials are simultaneously dehumidified and pre-treated during the conveying process through a vacuum feeding and drying integrated machine. Subsequently, the material enters a high-performance single-screw extruder, where it is fully plasticized into a uniform melt in a precisely temperature-controlled multi-heating zone, and then extruded through a mold with a hanger type runner design to form a continuous parison.

The parison is immediately placed on the shaping platform equipped with three independent vacuum control zones. By adjusting the negative pressure intensity and cooling rate in sections, the cross-sectional contour of the product is clear and the dimensional tolerance is strictly controlled within ±0.3mm. After the profiles are shaped, they are stably pulled out by a servo synchronous traction machine, precisely cut to the set length by a flying saw cutting machine, and finally enter the surface treatment unit to complete decorative processes such as wood grain transfer, UV spraying or film coating. The entire line is controlled by a PLC central control system to achieve closed-loop monitoring and data traceability of parameters such as temperature, pressure and speed.

![conical twin screw extruder]()

SJ 55/28 single screw extruder

The solid PVC mixture is transformed into a uniform, stable and moldable melt, laying the foundation for the subsequent molding process

![Vacuum shaping platform (6 meters)]()

vacuum sizing platform

The high-temperature softened parison output by the extruder is permanently fixed to the precise cross-sectional shape and size required by the design through precise cooling and shape control, and the desired surface quality is endowed to the product. It directly determines the final appearance accuracy, geometric stability and performance in use of the product.

![Tractor Cutting Integrated Machine]()

Traction Machine

Provide stable, continuous and controllable pulling force for the entire production line, ensuring that the entire process from extrusion, shaping to cutting is carried out under precisely synchronized tension and speed

Cutting Machine

Precisely cut the continuously produced infinitely long profiles into the specified lengths that meet the order requirements, and ensure that the cut quality satisfies the installation and aesthetic requirements

![Stacker]()

stacking

Receive individual products from the cutting machine according to the preset program

Ⅳ. Application field

1. Home decoration field

Kitchen and bathroom space: Moisture-proof and rust-proof, suitable for high-temperature and high-humidity environments, can hide water and electricity pipes, integrated bathroom heaters and exhaust equipment.

Basement: Moisture-resistant and mold-proof, supporting moisture-proof gypsum board or aluminum ceiling panels, suitable for the ceiling of storage rooms and leisure areas.

Balcony: Resistant to ultraviolet oxidation, suitable for ceiling renovation after balcony sealing, and can install load-bearing brackets for clothes drying machines.

Entrance foyer: It has strong load-bearing capacity and can be combined with magnetic track lights and suspended ceiling designs to enhance the sense of spatial layering

2. Workwear field

Commercial Spaces: Shopping malls, supermarkets, office buildings. Large areas of flat ceilings can be built, suitable for the installation of central air conditioning, fire sprinklers, and monitoring equipment.

Medical facilities: Hospitals, clinics, moisture-proof, antibacterial, easy to clean, meeting hygiene standards, and capable of hoisting medical equipment brackets.

Industrial plant: Strong load-bearing capacity, suitable for heavy-duty lighting and ventilation systems, strong corrosion resistance, suitable for high-humidity production workshops.

Transportation hubs: Airports, high-speed railway stations, fireproof and flame-retardant, anti-deformation, suitable for large-span ceiling construction

Educational institutions: Schools, training institutions, sturdy and durable, capable of long-term use in crowded scenarios

3.Special fields

Soundproof and heat-insulating Spaces: Audio-visual rooms, machine rooms. Rock wool/sound insulation cotton is filled in the gaps of the keel to enhance the noise reduction effect.

High load-bearing demand Spaces: Stages, studios, capable of hoisting heavy equipment such as lighting and sound systems.

In damp and saline-alkali environments: For buildings in coastal areas, the galvanized coating resists saline-alkali corrosion and extends the service life of the ceiling

![ceiling product 1]()

Ⅴ. FAQ

Q1.How to pay to you?

A:1)30% of total amount paid by TT as advance, then the seller start production

2)after the machine is finished ,buyer come to test the machine in seller's factory ,

and then pay the 70% balance by TT or irrevocable L/C at sight . Then seller ship the machine.

Q2.How long is the delivery time?

A: For standard machines, it would be 30 days; For non-standard machines and customized machines according

to client s specific requirements, it would be 45 days.

Q3.Do you arrange shipment for the machines?

A:Yes,for FOB or CIF price, we will arrange shipment for you.

Q4.How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by clients.

Q5.What's your after-sales service ?

(1)The supplier provides service manual and maintenance instruction of main electric appliances, limb, usage manual of equipment. We also supply water, electricity, gas of equipment and installation drawing.

(2)The supplier is responsible for installation, debugging and training, but the air tickets, insurance, eating, housing and every day 100 USD for each engineer will be born by the buyers. We will realize guarantee of repair; replacement and refund of substandard products within one year after the machine leaves factory. And half a year for electric parts. Fittings of the machine will be supplied at preferential price after one year.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province