Ⅰ. Overview

Steel wire strip is a flat metal product with high strength, corrosion resistance and stable structure, which is made through special processes such as precise drawing, heat treatment and surface coating. Its manufacturing process endows it with excellent tensile strength, fatigue resistance and the ability to resist environmental corrosion. This characteristic makes it a key reinforcing material in modern pipeline engineering, widely used in fields with extremely high performance requirements: in RTP (Reinforced thermoplastic) pipelines, it serves as the core reinforcing layer, withstanding the main pressure, endowing the pipeline with both flexibility and pressure-bearing capacity, and is suitable for high-pressure oil and gas transportation. In the traditional repair of oil and gas pipelines, it is used for helical winding reinforced

1.Basic info

Model NO. | SJ75/30 | Type | Profile Extruder |

Plastic Processed | PP | Product Type | Extrusion Molding Machine |

Feeding Mode | One Feed | Assembly Structure | Integral Type Extruder |

Screw | Single-Screw | Engagement System | Full Intermeshing |

Screw Channel Structure | Deep Screw | Exhaust | Exhaust |

Automation | Automatic | Computerized | Computerized |

Barrel Heating Power | 160W | Main Motor Speed | 1480r/Min |

Production Line Speed | 120m/Min | Screw Diameter | 75mm |

Screw Length-Diameter Ratio | 30:1 | Transport Package | Conventional Packing |

Specification | 100mm | Trademark | Zhongrui |

Package Size | 3500.00cm * 350.00cm * 350.00cm | Package Gross Weight | 5000.000kg |

Origin | Qingdao China | Production Capacity | 1000 |

Ⅱ. Equipment features

1. Based on a robust design and advanced manufacturing process, this equipment achieves a low failure rate, smooth and silent operation, and also features excellent wear resistance and convenient maintenance, significantly enhancing the overall operational efficiency.

2. This device achieves an operation experience that is "ready to use upon startup and worry-free and labor-saving" through the deep integration of a safety protection system, humanized interaction design, process automation and intelligent assistance. This not only significantly reduces personnel training costs and operational loads, but also directly translates into a remarkable increase in production efficiency and economic benefits by enhancing the pace and reliability of operations.

3. This equipment is not a simple accumulation of various advantages, but a systematic project that ultimately achieves high-efficiency output through advanced technology core drive, precise mechanical load-bearing, compact structure support, and stable performance guarantee. It not only meets the current production demands of high precision and high rhythm, but also reserves space for future digital and intelligent upgrades with an open architecture, providing customers with technical solutions that have long-term competitiveness.

4. This equipment, through a closed-loop mode of “central intelligent control + real-time process linkage + online quality feedback”, upgrades automation from simply “replacing human labor ”to a core capability of “ensuring the optimal process and constant quality”

5. This device not only enhances the quality of the working environment and brand image through highly recognizable aesthetic design, but also ensures long-term reliable operation under harsh working conditions with solid materials and a sturdy structure. Meanwhile, its deeply integrated energy-saving technology significantly reduces the total life cycle usage cost, demonstrating a dual commitment to economic benefits and environmental responsibility.

Ⅲ. Introduction

1,classification: | according to the process is divided into embossed packaging belt, plane packaging belt /according to the color is divided into colorless transparent packaging belt, green, black and other color packaging belt. |

2, appearance: | smooth packaging with smooth surface, embossed packaging with prismatic pattern. |

3, flammability: | flammable, leave the flame to continue to burn. The flame is yellow, smoky, slightly expanded, sometimes cracking. |

4, application: | widely used in iron and steel, aluminum, chemical fiber, cotton spinning, tobacco, paper industry, metal can and other industries. |

Ⅳ. Production line

Steel wire strip is a flat metal product with high strength, corrosion resistance and stable structure, which is made through special processes such as precise drawing, heat treatment and surface coating. Its manufacturing process endows it with excellent tensile strength, fatigue resistance and the ability to resist environmental corrosion. This characteristic makes it a key reinforcing material in modern pipeline engineering, widely used in fields with extremely high performance requirements: in RTP (Reinforced thermoplastic) pipelines, it serves as the core reinforcing layer, withstanding the main pressure, endowing the pipeline with both flexibility and pressure-bearing capacity, and is suitable for high-pressure oil and gas transportation. In the traditional repair of oil and gas pipelines, it is used for helical winding reinforced.

![pay off rack]()

![line following rack]()

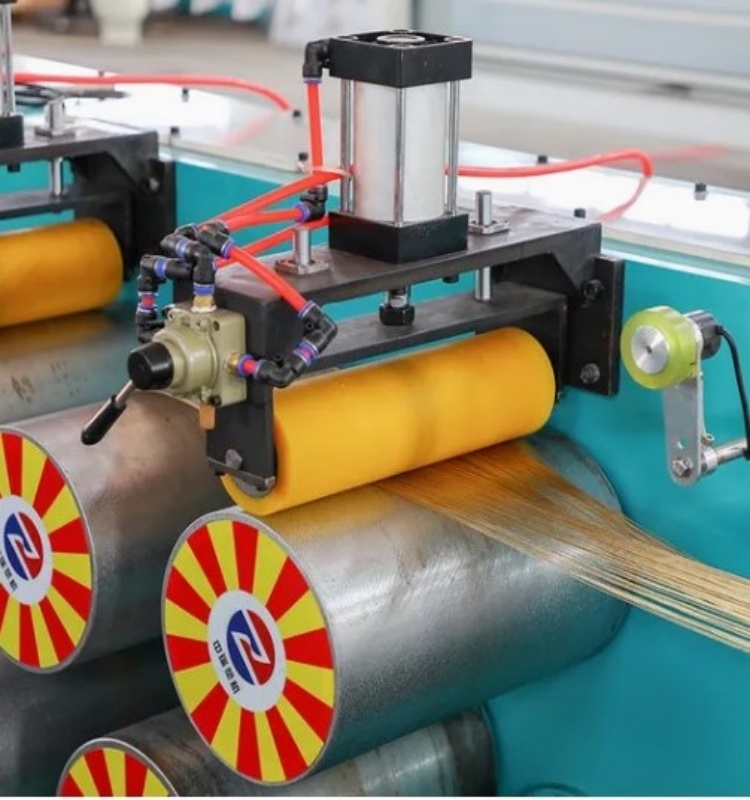

![double-roller(water cooled)]()

![tractor]()

![winding machine]()

![product]()

Ⅴ. After sales service

1. Free installation and debugging of products, providing corresponding technical training and daily equipment operation and maintenance training.

2. During the quality assurance period, if any malfunction occurs due to quality issues, responsible for equipment warranty.

3. By purchasing our company's equipment, we will wholeheartedly serve you for life and provide you with problem-solving solutions.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province