You need to know about plastic extrusion speed to compete in 2025. The speed of your plastic extrusion process affects product quality and efficiency. Fast plastic extrusion speed can help you make more products. But it can also change melt quality and how even it is. New technology, like AI-driven monitoring and better die designs, helps you control plastic extrusion speed for better results. These new tools lower downtime, cut waste, and help make production greener. The effects of extrusion speed touch every part of your work process. Making plastic extrusion speed better gives you an advantage and helps you keep up with new needs. The effects of extrusion speed are more than just making more products.

Key Takeaways

Material properties like melt flow index, viscosity, and thermal stability affect how fast you can run plastic extrusion. If you go too fast, you might lose quality.

Machine setup is important. Nozzle size, calibration, and temperature control help balance extrusion speed and product consistency.

New technologies help a lot. AI-driven controls, smart sensors, and digital twins watch and change extrusion speed. This makes things more efficient and creates less waste.

Good die design is needed. Smooth flow, cooling channels, and modular parts let you go faster. They also keep product quality high and downtime low.

You must balance speed and quality. Going too fast can cause defects and cost more. Going too slow means you make less. Use process monitoring and team training to find the best speed.

Factors Affecting Speed

Material Properties

It is important to know how material properties affect extrusion speed. The melt flow index (MFI) shows how fast plastic moves when heated. If the MFI is higher, plastic goes through the extruder faster. This means you can run the machine at a higher speed. Viscosity is also important. When viscosity is low, plastic flows easily. This helps the extruder work fast without clogging or uneven flow. Thermal stability matters too. Plastics that stay stable at high heat let you use faster machines. Additives can change how plastic acts. Some additives help plastic move faster, while others slow it down.

Melt Flow Index (MFI): Higher MFI means faster speed.

Viscosity: Lower viscosity means smoother and faster extrusion.

Thermal Stability: More stability means you can go faster.

Additives: These can make extrusion faster or slower.

Different polymers change how fast you can run high-speed extruders. Some plastics, like semi-crystalline polymers, need careful cooling and temperature control. This keeps the quality high. The way you set screw speed and mixing parts changes how long plastic stays in the extruder. If you turn up screw speed, you get more output. But this can make the product less even. You need to match the polymer’s melt viscosity and thermal stability with the right speed. This helps you make strong and even products.

Machine Configuration

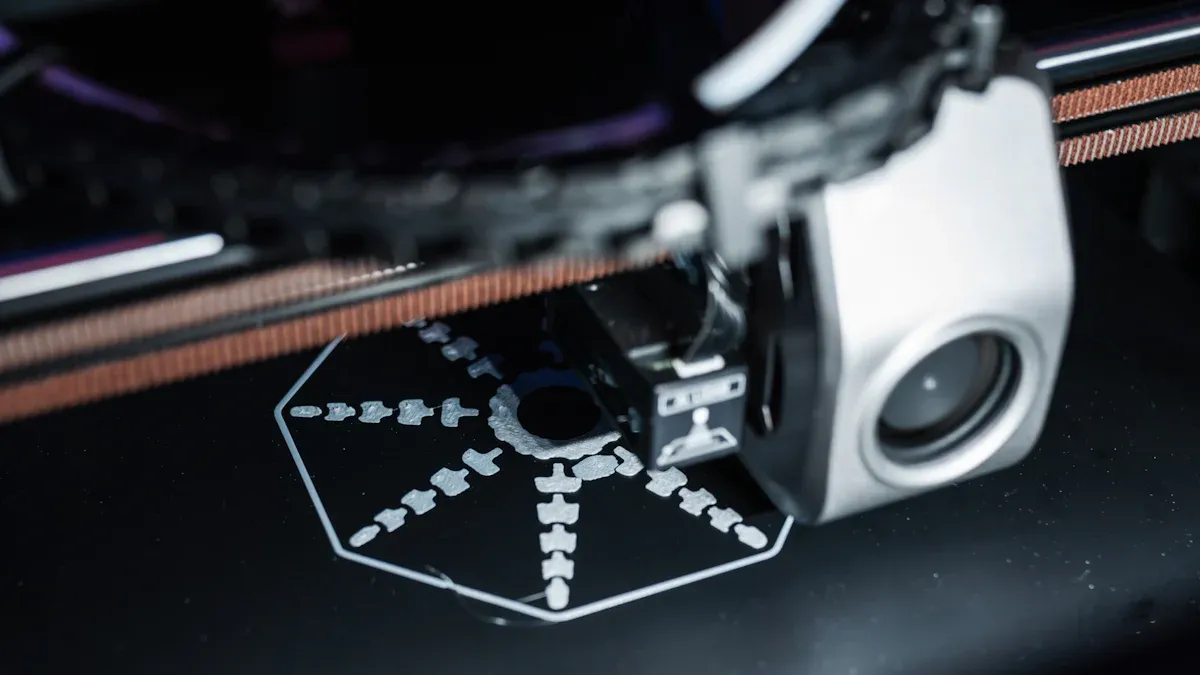

Your machine setup decides how fast you can run extrusion. Nozzle diameter is very important. A bigger nozzle lets more plastic out. This means you can use high-speed extruders for larger jobs. Layer height and printing speed also matter, especially in 3D extrusion. For example, a nozzle size of 0.45 mm, layer height of 0.8 mm, and print speed of 7 mm/s work well for many fast machines.

You should check hardware quality too. Good hotends, strong stepper motors, and well-set extruders help you go faster. Calibration is very important. You need to level the bed, set the right temperature, and adjust the axis. This keeps the process smooth. Slicing software settings, like print speed and layer thickness, also change how fast you can extrude plastic. Environmental factors, like bed and room temperature, affect how plastic flows and sticks. Cooling fans, tool path choices, and part direction all help balance speed and quality.

Temperature and Pressure

You must control temperature and pressure to keep extrusion steady and fast. In high-speed extruders, the right temperature melts plastic evenly. For example, PVC sheet extrusion works best between 160°C and 200°C. If the temperature is too low, plastic does not melt well. If it is too high, the material can burn.

Pressure inside the extruder changes with screw speed and feed rate. If you turn up screw speed, you get more shear heat. This raises melt temperature and pressure. This can help you run machines faster, but you must watch for problems. If pressure or temperature changes too much, you get uneven filament and bad quality. Stable pressure means steady speed and better results.

Pressure changes can make the extruded plastic’s diameter change.

Higher screw speeds can cause more pressure swings and less even products.

Lower screw speeds give more steady pressure and better results.

Real-time pressure checks help you find problems early.

You need to balance temperature and pressure to get the best speed and quality from high-speed extruders.

Die Design

Die design is a big part of how fast you can run extrusion. The die shapes the plastic as it leaves the extruder. If you use new design tools and simulation software, you can make the die for smooth flow and fewer problems. Artificial intelligence now helps you pick the best die design and settings. Additive manufacturing lets you make dies with special shapes and cooling channels. This helps control heat and lets you go faster.

Tip: Use modular die heads to cut downtime and switch jobs quickly. This can make your production up to 25% more efficient.

Here are some important die features for high-speed extruders:

Smooth die shape for even flow and less turbulence.

Good draft angles for easy removal and nice surface finish.

Good cooling channels to keep temperature steady.

Strong materials for longer die life at high speeds.

CAD and simulation tools to control flow and heat.

Die design that matches the plastic’s viscosity and heat needs.

Easy access for maintenance to cut downtime.

Additive manufacturing for special shapes and better cooling.

A good die design keeps plastic flowing evenly and stops defects. It lets you use fast machines without losing quality. For example, a European plastics company made 30% more products after using a die head with adjustable land lengths and better cooling.

Die Feature | Benefit for High-Speed Extruders |

Smooth geometry | Fewer defects, higher speed |

Integrated cooling | Keeps temperature and viscosity steady |

Modular design | Faster changes, less downtime |

Smart sensors | Real-time fixes, fewer defects |

You need to match your die design to the plastic and the speed you want. This helps you get the best results from your extrusion process.

Measuring Speed

Measurement Methods

It is important to measure extrusion speed the right way. This helps you make sure your plastic products stay the same every time. Factories today use different ways to check speed:

Motor speed control uses special drives. These drives let you change how fast the motor goes by changing voltage and frequency.

Die head adjustment lets you change how much plastic comes out. You do this by making the die opening bigger or smaller. This changes the shape and speed of the plastic.

Temperature control changes how runny the plastic is. If the plastic is more runny, it moves faster.

Rubber supply device control lets you change how much material goes in. If you feed more material, the speed can go up.

Extruder pressure control changes how fast plastic moves by changing the pressure. More pressure can make the plastic move faster.

New electronic controls, like special drives, help you keep the speed steady. These are better than old mechanical systems.

You can also use special testers called extrusion plastometers or melt flow index testers. These tools measure how much plastic goes through a die under certain rules. They follow ISO 1133 and ASTM D1238 standards. These testers help you get the same results each time you check speed. You should clean the tester after every use to keep your numbers right.

Industry Benchmarks 2025

In 2025, there are new normal speeds for plastic extrusion. Many factories use high-speed extruders now. These machines can turn screws at 100 to 300 rpm for most plastics. Some new machines can go even faster. But you have to watch out for problems with quality. You should look at your own speed and compare it to what other factories do. This helps you know if you need to get better.

Note: High-speed extrusion can help you make more products. But you must keep an eye on quality and not push your machine too hard.

Here is a table that shows normal speeds:

Material Type | Typical Extrusion Speed (rpm) | High-Speed Range (rpm) |

PVC | 60-120 | 150-250 |

Polyethylene (PE) | 80-180 | 200-300 |

Polypropylene (PP) | 70-160 | 180-280 |

Use these numbers as a starting point. Always check your own machine and plastic to find the best speed.

Output Calculations

You can figure out how much plastic you make with a simple formula. One way is:

O = (SW / 1000) * (3600 / CT)

O means output in kg per hour. SW means shot weight in grams. CT means cycle time in seconds. This formula helps you guess how much plastic you make at a certain speed.

Screw rpm and die size also change how much you make. If you turn the screw faster, you usually get more plastic. But if the die is too small, it makes more pressure and slows things down. Melt temperature and viscosity matter too. If you run the screw too fast, the plastic can get too hot and lose quality. Always try to balance screw speed, die size, and temperature. This helps you get the best speed and output.

High-Speed Extrusion

Process Overview

In 2025, high-speed extrusion uses new technology to work faster. These machines have special screws with mixing zones. This helps plastic move quickly through the machine. Better die designs lower pressure, so you get more output. Faster cooling and take-up systems help you make more products. You can make up to 40% more than with old machines. Smart features like IoT sensors and AI controls help the machine adjust itself. You can use touchscreens or voice commands to run the process. Energy-saving parts, like servo motors and induction heating, use less power. This can cut electricity use by up to 30%. Multi-layer co-extrusion lets you make products with up to nine layers. You can also change setups fast. Digital twin technology lets you test and watch your line without stopping work.

Better screw and die designs help you go faster

Smart controls and sensors help you make quick changes

Energy-saving systems lower your costs

Multi-layer and special extrusion options give you more choices

Benefits and Challenges

High-speed extrusion has many good points. You can run machines all the time with less work. This makes things more efficient. These machines use less energy and make less waste. You get products that look the same every time. You can make complex shapes and change molds fast. Many types of plastics work, even ones you can recycle. Automation helps you make fewer mistakes and less scrap.

But there are some problems too. Some plastics do not work well at high speed. This is because of their melt temperature or viscosity. You might see problems like uneven sizes or bad surfaces. It can be hard to control melt and temperature. High-speed machines need regular care to stop them from wearing out. You must watch for bubbles or bent parts. You also need to think about energy use and pollution. Skilled workers and smart systems help keep things running well.

Aspect | High-Speed Extrusion | Standard-Speed Extrusion |

Extruder Diameter | 60-75 mm | 150 mm and above |

Screw Speed | 400-1500+ rpm | Much lower rpm |

Energy Consumption | 10-15% less, more efficient | Higher energy use |

Machine Size | Compact, smaller footprint | Larger, bulkier |

Output | High throughput, faster color change | Lower throughput, slower changes |

Quality Considerations

You need to focus on quality when using high-speed extrusion. Clean and check your machines every day. Look at sensors and set up equipment often. Change settings like temperature, pressure, and screw speed to keep things steady. Use checks during work, like taking samples and looking for problems. Train your team to use the machines and spot issues. Use process control to watch your speed and quality. Look for defects like warping, bubbles, or rough surfaces. Pick good raw materials and keep your work area at the right temperature and humidity. Good die design and care help you stop surface problems and keep sizes the same.

Tip: Keep making your process better by getting feedback and doing checks. This helps your high-speed extrusion line stay fast and make good products.

Speed and Quality

Product Consistency

You need to keep your products the same every time. The speed of your extrusion process plays a big role in this. When you use high-speed extrusion, you must watch how the plastic flows. If the speed is too high, the plastic may not cool or harden the right way. This can make your products the wrong size or shape. If you run the extrusion too slowly, you lose efficiency and may overheat the material. This also hurts the final product. You must set the right speed to get steady flow and good results. Good quality control checks help you spot problems early. You can use sensors and cameras to watch for changes in size or shape. This keeps your products consistent and helps you meet customer needs.

Cost and Throughput

You want to make more products in less time. High-speed extrusion lets you do this. When you increase speed, you boost throughput and can fill more orders. But you must think about the cost. Running machines at top speed uses more energy and can cause more waste if you do not have strong quality control. In 2025, many factories use new technology to balance speed and efficiency. For example, some machines use less energy at certain speeds. If you go too fast, you may spend more on power and repairs. You need to find the best speed for your material and machine. This helps you lower costs and keep efficiency high. The implications of extrusion speed reach every part of your business, from energy bills to how many products you ship.

Note: Using softer plastics or better motors can help you save energy and money during high-speed extrusion.

Balancing Speed and Quality

You must balance speed and quality in every extrusion job. If you focus only on speed, you may see more defects and higher costs. If you slow down too much, you lose efficiency and cannot meet demand. The “Pick Two” rule says you can only have two out of three: speed, quality, or low cost. You need to talk with your team and set clear goals. Use quality control tools to check pressure, speed, and how the plastic moves. This helps you spot problems before they grow. High-speed extrusion works best when you control every part of the process. You can use smart sensors and software to watch for changes. This keeps your products strong and your costs low. The implications of extrusion speed show up in every finished part, so you must always check your process and make changes when needed.

Factor | Too Fast | Too Slow | Just Right |

Product Quality | Warping, bad shape | Overheating, slow output | Consistent, accurate |

Cost | High energy, more waste | Low waste, but less output | Balanced |

Efficiency | High, but risky | Low, safe | High and safe |

Quality Control | Hard to manage | Easier, but slow | Best results |

Best Practices in Speed Optimization

Latest Technologies

You can use new technology to make extrusion faster in 2025. Smart sensors and IoT systems help you watch your process all the time. These tools let you find problems early and keep machines running fast. AI controllers, like fuzzy logic systems, use live data to make quick changes. This keeps your process steady and lets you go faster without losing quality.

New materials are also important. Some new polymers melt at lower heat. This means you can run your extruder faster and save energy. You can use process modeling tools, like FEM simulations, to design screws and dies that fit your needs. Digital twins let you test and improve your line before you change anything for real. This helps you stop slowdowns and bottlenecks.

Here are some top technologies for 2025:

Smart sensors and IoT monitoring for real-time control

AI-driven controllers for instant process adjustments

Special polymers that melt at lower temperatures

FEM simulations for screw and die design

Digital twins for process testing and optimization

Advanced drive systems and induction heating for energy savings

Tip: Use digital twins to find and fix speed problems before they affect your production.

These tools help you reach higher extrusion speed and keep products the same. Many case studies show that factories using these tools have less downtime and better output.

Process Strategies

You can use different strategies to make extrusion faster and keep quality high. Start by making your process bigger. Increase how much you make, but watch things like residence time and shear stress. This helps you stop defects when you go faster.

Modular screw design gives you more control. You can change the screw to fit your material and speed. This keeps melt quality steady and helps you avoid shape problems. Melt pumps keep the flow steady, so pressure does not swing too much.

You should also work on process optimization. Change things like screw speed and barrel temperature to get the best results. Use advanced motor and drive controls to set the right speed. Die design is important too. A good die keeps flow even and shape correct at high speed.

Here is a table of key process strategies:

Strategy | Benefit for Speed and Quality |

Modular screw design | Balances throughput and melt quality |

Melt pumps | Reduces pressure swings |

Advanced drive controls | Precise speed regulation |

Die optimization | Maintains product shape |

Process monitoring | Quick problem detection |

Note: Always watch temperature, pressure, and flow rate. This helps you keep your process steady at any speed.

Many case studies show these strategies work well. Plants that use them often see faster speed, better efficiency, and fewer defects.

Customization for Applications

You can change your extrusion process for different products and materials. Start by picking the right screw and die design. Change the screw shape, like feed depth and compression ratio, to fit your polymer. This makes melt quality better and lets you go faster.

Material-specific designs help you handle special polymer needs. Some plastics need special mixing parts to stop clumps or bubbles. You can use special coatings on screws to stop wear and make them last longer. Simulation software shows how heat and pressure will change your process. This lets you make changes before you start making products.

Follow these steps to customize your extrusion process:

Change screw shape for your polymer and speed.

Use special designs for better melt and mixing.

Set features like length-to-diameter ratio to control time inside.

Add special coatings to stop wear and downtime.

Use simulation tools to test changes before you start.

Work with engineers to solve problems and make things better.

Callout: A custom screw for glass-filled nylon made throughput go up by 23%, scrap go down by 15%, and screw life three times longer. This shows how changing your process can make speed and efficiency better.

When you change your process for each job, you get better results. You can hit your speed goals, keep quality high, and work more efficiently. These best practices help you stay ahead in 2025.

You can do well in 2025 if you know what affects extrusion speed. Things like material quality, how you set up your machine, and watching the process all change how fast you go and what you make. To get faster, you can:

Buy new machines and use more automation.

Make your testing labs bigger and better.

Set up demo lines with new extrusion systems.

Get skilled engineers to help control the process.

If you follow what top companies do, you can stop slowdowns and go faster. You should:

Use special checks to keep your extrusion lines working.

Compare your speed and energy use to others.

Teach your team about new extrusion technology.

Use Industry 4.0 tools to watch and change speed right away.

Keep learning and try new ways to work. This will help you get the best speed, make better products, and stay ahead of others.

FAQ

What is the best way to increase extrusion speed without losing quality?

You should use smart sensors and AI controls. These tools help you watch the process and make quick changes. Good die design and steady temperature also help you go faster while keeping your products strong.

How do you know if your extrusion speed is too high?

Watch for signs like rough surfaces, bubbles, or uneven shapes. Use sensors and cameras to check your products. If you see more defects, your speed may be too high.

Can all plastics handle high-speed extrusion?

No, not all plastics work well at high speeds. Some need more heat or cool down slowly. Always check the material’s melt flow index and thermal stability before you increase speed.

What new technology helps control extrusion speed in 2025?

You can use AI-driven controllers, IoT sensors, and digital twins. These tools help you adjust speed, spot problems early, and keep your process steady.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province