You often see plastics everywhere, but do you know their melting points? Here’s a quick look:

Plastic Type | Melting Point (°C) |

HDPE | 130 |

LDPE | 110 |

PVC | N/A |

PET | N/A |

Polycarbonate | N/A |

PMMA | N/A |

Knowing the melting point of plastic helps you stay safe when using items near heat. You can choose the right materials for cooking, recycling, or building. This knowledge also keeps products strong and prevents damage during use.

Key Takeaways

Knowing the melting point of plastics helps you pick safe things for cooking and daily use.

Each plastic melts at a different temperature. Always read labels to stay safe in the microwave.

Recycling plastics the right way needs you to know their melting points. This helps make recycled items strong and safe.

Pick plastics that can handle heat for certain jobs. Use PET or polycarbonate for hot things.

Learn about the plastics you use. This helps you stay safe and care for the environment.

Melting Point of Plastic: The Basics

What Is Melting Point?

Have you ever heated a plastic spoon or bottle? The melting point of plastic is the temperature where solid plastic turns into a liquid. At this point, the plastic can flow and be shaped. Scientists say this happens when heat breaks the bonds in the plastic. The temperature stays the same while the plastic changes from solid to liquid. This lets companies make many things, like water bottles and pipes, from plastic.

The melting point of plastic is like ice melting into water. When you heat ice, it stays at one temperature until it melts. Plastics do the same thing, but each type melts at its own temperature.

The melting point of plastic is not always just one number. Some plastics melt quickly at one temperature. Others get soft over a range of temperatures. This depends on how the plastic is made and what it is made from.

Why Plastics Melt Differently

Not all plastics act the same when heated. The melting point of plastic changes for a few reasons:

Chemical Composition: The building blocks of plastic are called monomers. The forces between them decide how much heat is needed to melt the plastic. Crystalline plastics, like PET, have a clear melting point. Amorphous plastics, like PVC, get soft slowly over a range of temperatures.

Additives and Fillers: Companies add things to plastics to change how they act. For example, plasticizers make PVC softer and lower its melting point. Fillers like talc or calcium carbonate can make plastics stronger and sometimes raise the melting point of plastic.

Molecular Weight and Crystallinity: Plastics with bigger, heavier molecules usually have a higher melting point of plastic. If the molecules are packed tightly, as in semi-crystalline plastics, you need more heat to melt them.

You see these differences every day. Some plastic containers can hold hot soup. Others bend in the microwave. The melting point of plastic helps you pick the right material, whether you want something flexible, strong, or heat-resistant.

Melting Points of Commonly Used Plastics

![Melting Points of Commonly Used Plastics]()

Melting Points Table

You may wonder how the melting points of plastics compare. The table below shows melting points for different plastics. It helps you quickly see which plastic melts at what temperature.

Plastic Type | Melting Point (°C) | Melting Point (°F) |

Low-Density Polyethylene (LDPE) | 105–115 | 221–239 |

High-Density Polyethylene (HDPE) | 120–130 | 248–266 |

Polypropylene (PP) | 130–171 | 266–340 |

Polyvinyl Chloride (PVC) | 100–260 | 212–500 |

Polyethylene Terephthalate (PET) | 250–260 | 482–500 |

Polycarbonate (PC) | 220–230 | 428–446 |

Polystyrene (PS) | Softens ~100 | ~212 |

Nylon (Nylon 6) | 220 | 428 |

Nylon (Nylon 6,6) | 255 | 491 |

Polymethyl Methacrylate (PMMA) | 160 | 320 |

Tip: Knowing the melting points of plastics helps you pick the right one. If you need a plastic for high heat, choose one with a higher melting point.

Everyday Uses of Each Plastic

You see many plastics every day. Each type is used for a special reason. The melting point and other features decide where you find them.

Low-Density Polyethylene (LDPE):

LDPE is in plastic bags, wraps, and squeeze bottles. Its lower melting point makes it easy to shape into thin sheets. We use LDPE in machines to make packaging and farm films.

High-Density Polyethylene (HDPE):

HDPE is found in milk jugs, detergent bottles, and pipes. Its higher melting point lets it hold hot liquids safely. We use HDPE to make strong pipes for water and drains.

Polypropylene (PP):

PP is used in food boxes, car parts, and medical tools. Its melting point lets you clean medical items with heat. You also see PP in straps and fibers.

Polyvinyl Chloride (PVC):

PVC is used for pipes, windows, and wall panels. Its melting point lets you recycle and reshape it. You see PVC in building, wires, and floors. We use PVC machines to make products for homes and businesses.

Polyethylene Terephthalate (PET):

PET is in water bottles, soda bottles, and food packs. Its high melting point keeps drinks safe. PET is also used in straps for packing. Our PET machines make strong straps.

Polycarbonate (PC):

PC is found in safety glasses, lenses, and electronics. Its high melting point makes it good for things that need to resist heat and breaking.

Polystyrene (PS):

PS is in cups, food trays, and foam packs. It softens at lower heat, so do not use it for hot food or drinks.

Polymethyl Methacrylate (PMMA):

PMMA, or acrylic, is used for windows, dashboards, and panels. Its clear look and melting point make it great for signs and displays. We use PMMA in machines to make panels for many uses.

Note: Always think about the melting point when you pick a plastic. This helps you stay safe and makes your product last longer.

Different plastics have their own melting points and uses. If you want to know more or need help picking the right plastic, we at Qingdao Zhongrui Plastic Machinery Co., Ltd. can help. We have lots of experience with making pipes, sheets, and profiles to get the best results for you.

Melting Temperature of Plastic in Daily Life

![Melting Temperature of Plastic in Daily Life]()

Safety and Handling Tips

You use plastic things every day. These include food containers and kitchen tools. Knowing the melting temperature of plastic keeps you safe. It helps you avoid accidents at home. If you use the wrong plastic in the microwave, it can melt. It might also bend or let out bad chemicals. Polypropylene gets weak at 82°C (180°F). Polyethylene works better up to 130°C (266°F). Polycarbonate can handle up to 140°C (284°F). Always read the label before heating plastic.

Here is a simple guide for safe temperatures of plastics in appliances:

Plastic Type | Maximum Safe Temperature | Common Use |

Polypropylene (PP) | 82°C (180°F) | Food containers, straws |

Polyethylene (PE) | 130°C (266°F) | Bottles, bags |

Polycarbonate (PC) | 140°C (284°F) | Water bottles, lenses |

Polyamide (Nylon) | 220°C (428°F) | Cooking tools, gears |

PA (Polyamide) | 220°C (428°F) | Machine parts, textiles |

Polyamide and nylon can take more heat. This makes them good for cooking tools and machine parts. ABS plastic does not handle high heat well. So, do not use it for hot jobs.

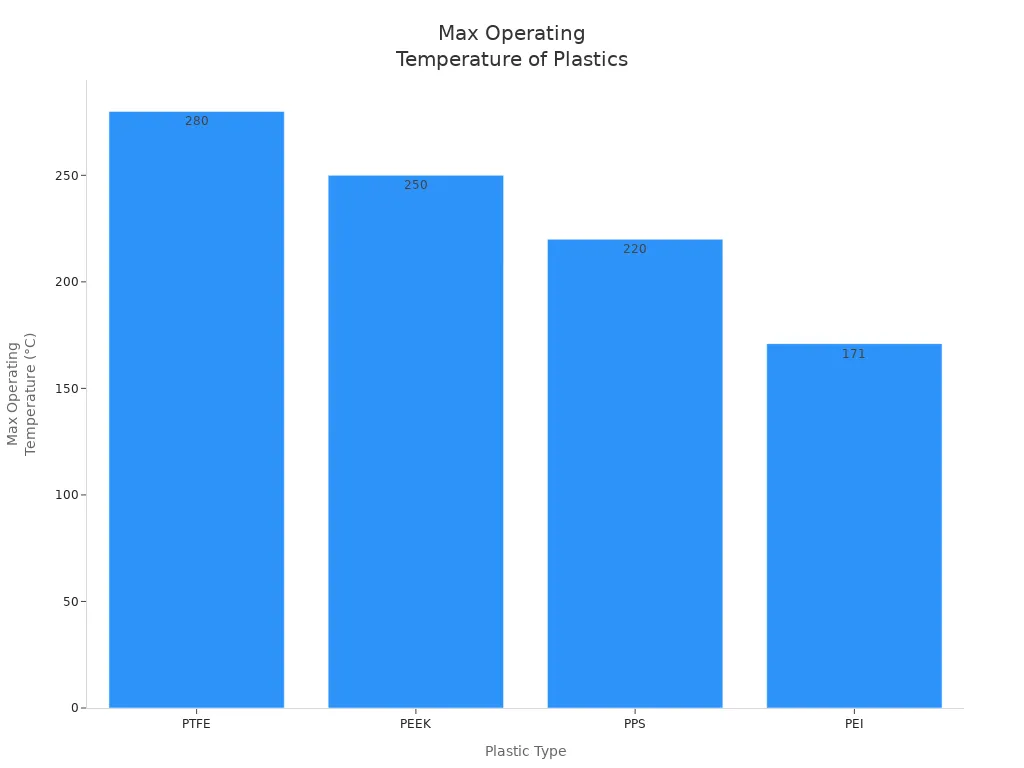

![Bar chart comparing max operating temperature of plastics used in appliances]()

Tip: Use plastics only within their melting temperature range. This helps you avoid burns, bending, or bad fumes.

Recycling and Product Choices

You help the planet when you recycle plastics the right way. Knowing the melting point helps recycling centers sort plastics. Each plastic melts at a different temperature. This makes sorting important for recycling. If you mix plastics with different melting points, the new product can be weak or unsafe.

Factories use the melting temperature of plastic to pick the best one. They choose plastics that will not bend or break when used. Polyamide is used for things that need to handle high heat. PET is used for bottles that must stay strong in hot weather. Keeping the right melting temperature during making keeps products safe and strong.

When you buy plastic things, look for recycling symbols. Check if the item fits your needs. If you need help picking the right plastic, Qingdao Zhongrui Plastic Machinery Co., Ltd. can help you. Our team knows about melting temperature ranges. We can help you get the best results.

Knowing the melting point of plastic helps you stay safe. You can keep yourself and the planet healthy by picking the right plastics. It is important to know which plastics are safe to use and how to recycle them.

Find out about different plastics so you recycle them right.

Always look at your town’s recycling rules before you recycle.

Pick products that fit what you need and can handle heat.

Do not put plastics like polypropylene near direct heat.

New tools, like melt sensors, help make plastic work safer. Use what you learn to use plastics safely and recycle better.

FAQ

What is the melting point of plastic?

Different plastics melt at different temperatures. LDPE melts at 110°C. HDPE melts at 130°C. PET melts at 260°C. Always check the label or ask the maker for the melting point.

Why does the melting point matter for recycling?

Sorting plastics by melting point helps recycling centers. This keeps recycled items strong and safe. Mixing plastics with different melting points can make weak or unsafe products.

Can I microwave all plastic containers?

No, not all plastics are safe in the microwave. Only use containers marked "microwave safe." Polypropylene is best for microwaving. Other plastics may melt or give off bad chemicals.

How do I choose the right plastic for my project?

Look at melting point, strength, and how you will use it. For hot jobs, pick PET or polycarbonate. For flexible things, choose LDPE or PVC. If you need help, ask Qingdao Zhongrui Plastic Machinery Co., Ltd. for advice.

Where can I get reliable plastic machinery?

Qingdao Zhongrui Plastic Machinery Co., Ltd. makes good plastic pipe, sheet, and profile machines. Our team gives expert help and after-sales service.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province