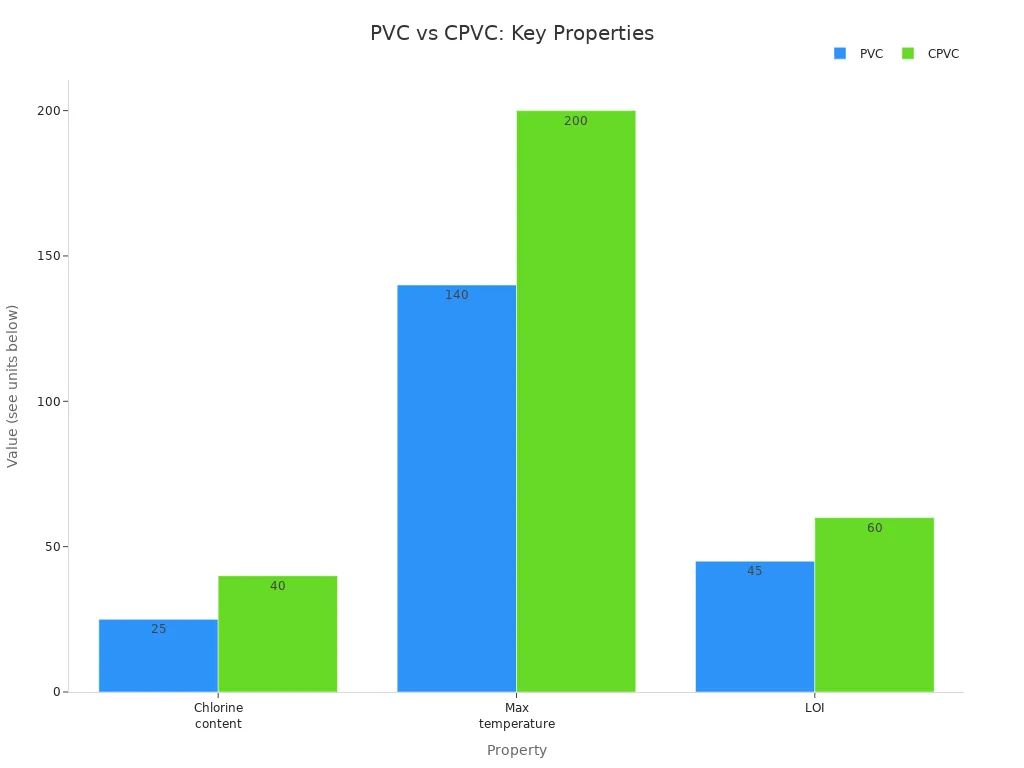

You need to know how pvc vs cpvc handle heat. PVC, or polyvinyl chloride, works well for cold water and drainage. It can resist temperatures up to 140°F. CPVC stands out with superior resistance and performance in hot water systems. You can use cpvc for temperatures up to 200°F. This extra 60 degrees makes a big difference in places like hot water lines, industrial piping, and areas with warm exhaust or chemical fumes. If you want durable pipes for high-temperature jobs, cpvc is the better choice.

You want pipes that last and can handle stress. CPVC pipes have high impact and tensile strength. You can rely on cpvc for tough jobs where pipes need to bend or take a hit. PVC pipes also offer good strength, but cpvc gives you more flexibility and durability in demanding environments. When you need pipes for places with movement or vibration, cpvc provides superior resistance and performance.

You can spot the difference between pvc vs cpvc by looking at their color. PVC pipes usually come in white or light gray. CPVC pipes often appear in off-white, cream, or light yellow. This color coding helps you identify the right material for your project. You should always check the markings on the pipe for size and type before installation.

You want to save money, but you also want durable pipes. PVC costs less than cpvc. For example, a ½” Schedule 40 pvc pipe costs $3-5 per 10-foot length. The same size cpvc pipe costs $4-7. For 1” pipes, pvc costs $7-10, while cpvc costs $9-13. CPVC is usually 25-30% more expensive than pvc of the same size and schedule. You should balance cost with the need for superior resistance and performance.

You need to match pipes and fittings for a leak-free system. PVC vs cpvc use different sizing standards. PVC usually follows the Nominal Pipe Size (NPS) standard. CPVC can use NPS or Copper Tube Size (CTS). This difference can cause confusion and compatibility issues. You should always check the size system before connecting pvc and cpvc pipes. The dimensions may not match, and you need different primers and solvents for joining.

You need strong joints so pipes do not leak. First, measure the pipe and mark where to cut. Use a pipe cutter or a small saw to cut it. Clean the edges and remove rough spots. Put solvent cement on the pipe and inside the fitting. Use a dauber to spread the cement. Push the pipe into the fitting and twist it a little. Hold it for half a minute to make it stick. Always check the instructions from the maker. Think about pipe size, heat, and air moisture for best results.

You need good tools to install pipes well. Use a pipe cutter, tape to measure, and a dauber for cement. Pick the right cement and primer for pvc or cpvc. Do not use dry fits, because they can leak. Cover the pipe and fitting with cement all over. Push the pipe all the way into the fitting. Use hangers and supports to hold pipes up. Let cpvc pipes move a little, since they change shape with heat.

You should stay safe when you work with pipes. Wear gloves and glasses to protect yourself. Work where air moves well, because cement fumes are strong. Look for problems in pipes before you start. Take your time and do not rush, or you might make mistakes. Do not use too many connectors, since they slow water down. Keep cpvc pipes safe from freezing by following rules. Always read and follow the maker’s instructions, especially for pipes with chemicals.

Residential Applications

You use pvc and cpvc pipes at home every day. These pipes help bring clean water and keep your house safe. PVC is best for cold water, drains, and watering gardens. You see pvc in garden hoses and drain pipes. CPVC is used for hot water in your house. You need cpvc when you want to move hot water safely. Both pvc and cpvc help carry drinking water. The table below shows how each pipe works in your home:

Pipe Type | Primary Uses | Temperature Tolerance |

PVC | Cold water supply lines, drainage systems, irrigation | Up to 140°F |

CPVC | Hot water distribution, residential plumbing | Higher than 140°F |

Tip: Always look at the temperature rating before picking a pipe for your house. This helps stop leaks and damage.

Commercial and Industrial Uses

You see pvc and cpvc pipes in many businesses and factories. PVC pipes are used for watering crops on farms. They also help move dirty water and rainwater. CPVC pipes are good for moving chemicals and hot liquids in factories. You use cpvc for chemical jobs and big piping systems. Both pvc and cpvc are strong and easy to put in place in factories and oil companies.

Agriculture: PVC pipes bring water to crops.

Chemical Processing: CPVC pipes move acids and strong chemicals.

Manufacturing: Both types carry safe liquids and air.

Oil and Gas: These pipes move fluids and gases.

Wastewater Management: PVC and cpvc help move dirty water safely.

Note: Qingdao Zhongrui Plastic Machinery Co., Ltd. makes pvc pipe machines and pvc profile machines for these business and factory needs.

Special Applications

Sometimes you need pvc or cpvc for special jobs. PVC is cheap and good for drains and watering. You use pvc for safe drinking water in factories. CPVC is better for hot water and strong chemicals. You pick cpvc for fire sprinklers and places with lots of heat. The table below shows special uses:

Material | Unique Applications |

PVC | Drainage, irrigation, potable water, industrial piping systems |

CPVC | Hot water distribution, chemical transport, fire sprinkler systems |

Tip: When you need strong pipes for special jobs, think about how much heat and chemicals each pipe can handle.

Choosing Between PVC and CPVC

Key Decision Factors

You need to pick the right pipes for your job. First, think about what kind of project you have. Is it for a house, a business, or a factory? Each one needs different things. Check if the pipes need to hold a lot of pressure. Some pipes must be strong, but some do not. Pipes outside need to last longer. Price matters too. You want pipes that work well and do not cost too much. Make sure the pipes are safe and have the right labels.

The weather can change how pvc and cpvc work. Sunlight and cold can make pipes weaker. Sometimes, the rules in your area say what pipes you must use. Always learn the rules before you start.

Here is a checklist to help you pick:

Tip: Pick pipes that fit your job and follow the rules.

When to Use PVC

Use pvc pipes for cold water and drains. PVC works well in homes, businesses, and factories. It is good for drain pipes, indoor plumbing, pipes underground, vent pipes, and main water lines. PVC can handle strong water flow and rain drains.

Application Type | Description |

Drain Lines | Used for sinks, toilets, and bathtubs. |

Indoor Plumbing | Commonly used in various indoor plumbing setups. |

Underground Plumbing | Suitable for underground installations. |

Vent Stacks | Effective for venting systems. |

Main Water Supply Lines | Used for main supply lines in buildings. |

High-Pressure Piping | Can handle high-pressure applications. |

Storm Drainage Systems | Ideal for stormwater management systems. |

PVC is best for cold water pipes. Do not use pvc for hot water. Hot water can make pvc pipes soft and bend. Flexible pvc gets soft at 50°C to 60°C. Hard pvc gets soft at 70°C to 90°C. The hottest pvc can handle is 140°F. If pvc gets too hot for a long time, it can leak or break.

Note: PVC saves money and works for many jobs. Always check if it can handle the heat and chemicals you need.

When to Use CPVC

Use cpvc pipes for hot water or strong chemicals. CPVC can take more heat and tough jobs. It is best for hot water pipes, moving chemicals, and fire sprinklers. CPVC does not rust and stays strong when hot.

CPVC is good for businesses and factories that need strong pipes. You can use cpvc for hot water at home and places with chemicals. CPVC does not get soft as fast as pvc when hot. It can work up to 200°F.

But cpvc can crack if it gets very cold. If you put cpvc pipes outside or where it freezes, be careful. Pipes need extra care below 40°F. CPVC can be used down to -15°F. Always teach workers and test pipes in cold places.

Here is a quick guide to help you choose:

Scenario | Recommended Material |

Cold water supply | PVC |

Drainage and venting | PVC |

Hot water distribution | CPVC |

Chemical transport | CPVC |

Fire sprinkler systems | CPVC |

Outdoor installations (mild climate) | PVC |

Outdoor installations (cold climate) | CPVC (with precautions) |

Tip: Use cpvc for hot water and chemicals. Use pvc for cold water and drains.

Limitations and Safety

Chemical Compatibility

It is important to know which chemicals can hurt PVC and CPVC pipes. Some things can make these pipes weak or break them. If you use the wrong chemical, your pipes might leak or stop working. Here are some chemicals that do not mix well with PVC and CPVC:

Caulks

Cleaners

Sealants

Fire stop products

Pipe clamps and tape

Thread sealants

Waterproofing agents

Spray foam

Oils and lubricants

Ketones like acetone and butanone

Plasticizers

Organic solvents such as esters, ethers, furans, alcohols

Aromatic hydrocarbons like benzene, cyclohexane, naphthalene

Ester oils

If these chemicals touch your pipes, they can cause cracks or leaks. The pipes can also lose their strength. Always check if a chemical is safe before you use it on pipes.

Health and Safety

You want pipes that keep your home or business safe. Sometimes, PVC and CPVC pipes can let out harmful stuff. Chemicals can get into drinking water from these pipes. When factories make PVC, they can release bad chemicals into the air. If pipes burn in a fire, they can make dangerous gases like benzene and styrene. Some chemicals in these pipes, like organotins and phthalates, can mess with hormones. These can be risky for kids and babies before they are born. The rules for drinking water may not always keep you safe from these risks. You should learn about these risks and pick pipes that follow safety rules.

Regulatory Considerations

You have to follow rules when using PVC and CPVC pipes. CPVC pipes for drinking water need special certifications like NSF/ANSI 14 and NSF/ANSI 61. ASTM and ISO standards help make sure CPVC fittings work, even in cold places. Safety rules say how pipes should work and how they act in cold weather. Fire safety rules are important for building projects. Local and national codes say PVC pipes must meet fire safety standards. If you do not follow these rules, you could have delays, pay more, or get into trouble.

Local rules may need pipes that fit the water in your area.

In Florida, new rules made people use more CPVC because it works with many water types.

Building rules can change which pipes you must use, depending on where you live.

Tip: Always check local rules and certifications before you start. This helps you avoid problems and keeps your building safe.

You have to pick the right pipe for your job. PVC is good for cold water and drains. CPVC is better for hot water and chemicals. Look at the table below to compare them:

Feature | PVC Pipes | CPVC Pipes |

Temperature | Up to 140°F | Up to 200°F |

Chemical Resistance | Good | Superior |

Flexibility | Rigid | Slightly flexible |

Choose the pipe that fits what you need. For tricky jobs, ask an expert or check local rules. Safe and careful work makes your pipes last longer.

FAQ

What is the main difference between PVC and CPVC?

You see the biggest difference in temperature resistance. PVC handles cold water and drains. CPVC works for hot water and chemicals. CPVC has more chlorine, so it resists heat better.

Can you use PVC for hot water lines?

You should not use PVC for hot water. PVC softens and may leak above 140°F. Choose CPVC for hot water pipes. CPVC stays strong up to 200°F.

How do you identify PVC and CPVC pipes?

You can check the color and markings. PVC pipes are white or gray. CPVC pipes are cream or yellow. Look for labels like "PVC SCH 40" or "CPVC SCH 40" on the pipe.

Do PVC and CPVC need different glues?

You must use the correct solvent cement for each type. PVC cement works only for PVC pipes. CPVC cement bonds CPVC pipes. Mixing glues can cause leaks.

Are PVC and CPVC pipes safe for drinking water?

You can use both for drinking water if they meet safety standards. Always check for certifications like NSF/ANSI 61. Follow local codes to keep your water safe.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province