An extruder machine shapes raw plastic into things we use. You put plastic pellets or powder into the machine. The machine heats and mixes the plastic. Then it pushes the plastic through a shaped opening. This makes pipes, sheets, or packaging straps. Extruder machines are used in many places. They help industries like construction and packaging. More people want these machines because they work fast and use new technology.

The global plastic extrusion machine market was USD 6,408.4 million in 2022.

The market grows as more industries use plastic and care about the environment.

Key Takeaways

Extruder machines turn raw plastic into things we use. These things include pipes and packaging. Many industries need extruder machines. Construction and packaging companies use them a lot.

The extrusion process has several steps. First, the plastic is heated. Then, it is mixed and shaped. The plastic melts during this process. Contaminants are removed. The final product is cooled.

Picking the right extruder is important. You can choose a single-screw or twin-screw extruder. This choice affects how well the machine works. It also affects the quality of the product. Each type is good for different jobs.

Modern extruder machines use automation. This helps control temperature and pressure better. Products are higher quality. There is also less waste.

Extrusion technology is very flexible and good for the environment. It can use many types of plastics. It helps companies meet market needs. It also uses less energy.

What is an extruder machine?

Definition and Purpose

You might ask what an extruder machine does. It takes raw materials like plastic pellets or powder. The machine mixes and pushes these materials through a barrel. It uses one or two screws to do this job. High heat and pressure help shape the material. The process makes items with certain textures and shapes.

The extruder machine works like a plug flow reactor. It mixes materials in many directions, not just straight ahead. When things get very hot, solids melt and flow. This helps make different shapes and textures.

Here is a simple table that explains the most common definition in industrial engineering:

Definition | Description |

Extruder | A machine that blends and pushes flours or grains through a barrel with one or two screws. It uses high heat and pressure to make products with open textures. |

Extruder machines make products that come out in long pieces. These machines are important in factories today. They help improve quality, save money, and work faster. Picking the right extruder machine gives you better results and saves resources.

We design and build different extruder machines at Qingdao Zhongrui Plastic Machinery Co., Ltd. Our products include single screw and twin screw extruders. You can use them for many plastic processing jobs.

![What is an extruder machine]()

Main Applications

You see extruder machines used in many industries. These machines help make things you use every day. Here are some main uses:

Pipes: Used for water, sewage, and gas. You find these pipes in homes, factories, and farms.

Profiles: Includes uPVC window frames, door frames, and vinyl siding. These profiles are used in building and home projects.

Sheets: PVC or polycarbonate panels for roofing and insulation. You see these sheets in buildings and greenhouses.

Packaging Straps: PET and PP strapping belts for tying boxes and pallets. These straps are important in shipping and moving goods.

You also find extruder machines in packaging, construction, cars, medicine, and consumer goods. For example, extruded pipes and profiles are used in chemical plants and farming. Drip irrigation tubes made from PE extrusion lines help farmers save water.

We offer special production lines like the PVC pipe line and PET strapping line. These help you make pipes, profiles, sheets, and packaging straps with steady quality.

If you need machines for making plastic pipes, sheets, or packaging straps, you can trust our skills and new technology. We work to give you solutions that fit your needs and help you make products efficiently.

How an extruder machine works

The Extrusion Process

The extrusion process has several easy-to-follow steps. Each step changes raw plastic into a finished item. Here is a simple table that lists the main steps:

Step | Description |

1 | Raw plastic pellets are fed into a hopper and enter the extruder |

2 | Material travels through a heated barrel where it melts (200-275°C) |

3 | A rotating screw compresses and homogenizes the molten plastic |

4 | Screens and breaker plates remove contaminants and create back pressure |

5 | Molten plastic is forced through a die to create the desired profile |

6 | The extruded product is cooled to solidify its shape |

7 | The product is cut to length or wound onto spools. |

First, you put plastic pellets or powder into the hopper. The material moves into the barrel, where heaters make it hot. Most plastics melt between 160°C and 220°C. PVC melts between 160°C and 200°C. The screw inside the barrel turns and pushes the melted plastic forward. The pressure inside the barrel can be very high, from 1,000 to 5,000 psi. This pressure shapes the plastic and removes air bubbles.

As the plastic moves forward, screens and breaker plates catch any dirt. The melted plastic then goes through a die. The die gives the plastic its final shape, like a pipe or sheet. After shaping, the product goes into a cooling system. Cooling makes the plastic hard and keeps its shape. At the end, you cut the product to the right size or wind it onto spools for storage or shipping.

Tip: The extrusion process works best when you watch the temperature and pressure closely. This helps the product have a smooth surface and stay strong.

Key Components

Every extruder machine has important parts. Each part does a special job. The table below shows what each part does:

Component | Role |

Hopper | Introduces raw material into the extruder and feeds it into the processing chamber. |

Screw(s) | Rotating elements that move and mix the material through the processing chamber. |

Barrel | Main chamber housing the screw, typically heated to facilitate melting or softening. |

Heating and Cooling Systems | Maintain the required temperature for material processing and prevent overheating. |

Die or Nozzle | Shapes the material as it exits the extruder, determining the final product's profile. |

Screen Packs and Filters | Remove impurities from the material before it enters the die. |

Drive System | Provides power to rotate the screw(s) and move material through the extruder. |

Control System | Manages extrusion parameters like temperature and pressure for consistent output. |

Cutting or Sizing Mechanism | Trims the extruded material to the desired length or shape. |

Cooling and Conveying System | Solidifies the extruded material and transports the finished product away. |

Safety Features | Ensures safe operation and protects operators from hazards. |

You pour the raw material into the hopper. The screw pulls the material into the barrel. Heaters around the barrel melt the plastic. The screw mixes and pushes the melted plastic forward. The die at the end shapes the plastic as it leaves the machine. Cooling systems, such as water baths or air blowers, help the product keep its shape. Cutting machines or winders finish the process by making the product ready for use.

Modern extruder machines use advanced automation and intelligent control systems. These systems help you keep the temperature and pressure steady. They make real-time adjustments to the process. You get better quality and less waste. Automated dies and bolts let you change the thickness of sheets or straps quickly. Optical sensors measure the product as it comes out, so you can fix any problems right away. This technology saves time and reduces costs.

Note: Automation in extrusion means you spend less time checking the process and more time making high-quality products.

You can see how each part of the extruder machine works together. This teamwork gives you strong, smooth, and reliable plastic products every time.

Types of extruder machines

There are different types of extruder machines you can pick. Each type is good for certain jobs and materials. Here are the main choices you will see in the industry.

Single-Screw Extruders

Single-screw extruders have one screw inside the barrel. Many factories use these machines because they are easy to use and dependable. They are good for jobs that need steady work and simple mixing.

Common uses for single-screw extruders:

Plastic pipe making

Polyethylene and polypropylene work

PVC profiles

Medical tubing

Making plastic pellets for recycling

Film extrusion for packaging

Sheet extrusion for building

Single-screw extruders work best with clean, even materials. They are simple to run and cost less. You can also change these machines for special tasks.

Twin-Screw Extruders

Twin-screw extruders have two screws that fit together. These machines mix and feed materials better. They can handle many kinds of materials, even blends and additives.

Advantages of twin-screw extruders:

Faster production with higher output

Better mixing and spreading

Improved heat control for sensitive materials

Good at removing unwanted gases

Can be used for thermoplastics, food, and special products

Easy to make bigger for large projects

You use twin-screw extruders for harder jobs. These machines help make products that need high quality, like coatings, compounds, and special plastics.

Comparison Table:

Feature | Single-Screw Extruder | Twin-Screw Extruder |

Design | One screw | Two intermeshing screws |

Mixing Performance | Moderate | Excellent |

Output Capacity | Medium | High |

Process Control | Basic | Precise |

Maintenance | Easy | Moderate |

Ideal For | Simple, large volume tasks | Complex, high quality tasks |

Other Types

Some jobs need special extruders. Multi-screw extruders and custom machines are made for certain industries.

Examples of specialty extruders:

Rubber products like profiles, seals, and hoses

Food processing for snacks, cereals, and pet food

Pharmaceuticals for drug delivery systems

Recycling plastic waste into pellets

Adhesives and sealants

Mastics, soaps, and chemicals

You choose the right machine for your material and product. Qingdao Zhongrui Plastic Machinery Co., Ltd. has machines for every job, from simple pipes to advanced food and medical products.

Tip: Always pick the extruder type that matches your production needs. This helps you get the best results and save materials.

Materials and benefits

Common Materials Processed

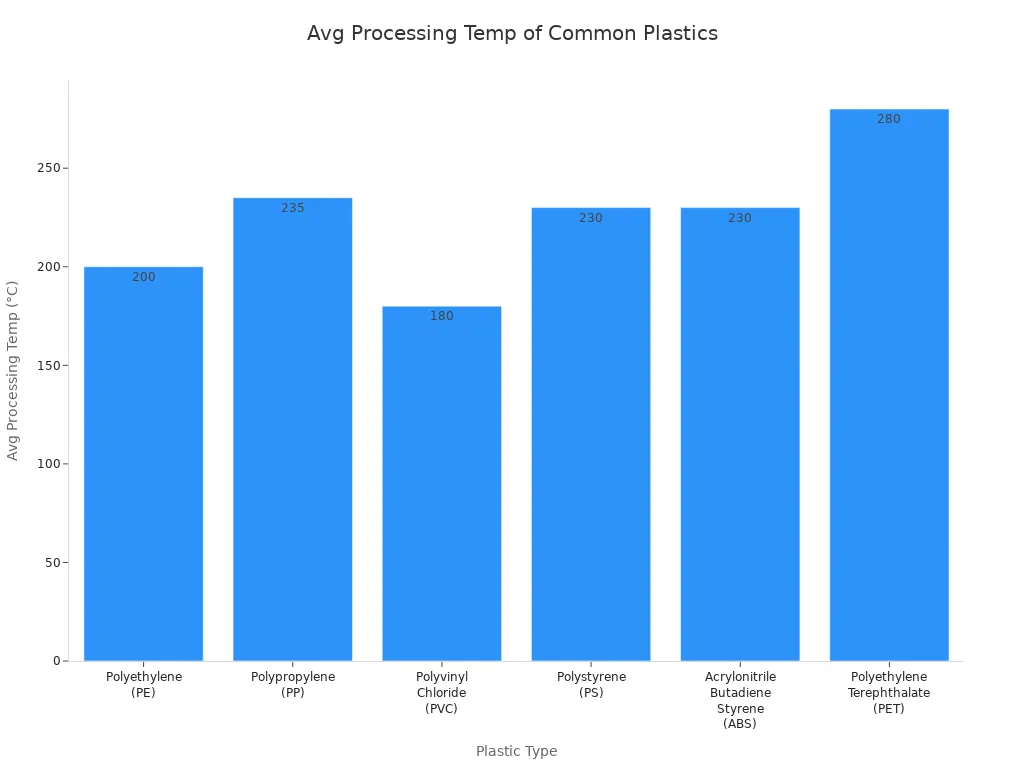

Our machines can work with many kinds of plastics. Each plastic has special uses and features. The table below shows common plastics, their melting temperatures, and what they are used for:

Plastic Type | Processing Temperature (°C) | Applications |

Polyethylene (PE) | 160-240 | Water pipes, shopping bags |

Polypropylene (PP) | 200-270 | Automotive components, packaging |

Polyvinyl Chloride (PVC) | 160-200 | Construction applications |

Polystyrene (PS) | 180-280 | Packaging, consumer products |

Acrylonitrile Butadiene Styrene (ABS) | 200-260 | Automotive components, electronics |

Polyethylene Terephthalate (PET) | 260-300 | Bottles, fibers |

![Bar chart comparing average processing temperatures of common plastics in extruder machines]()

You find these plastics in lots of things. They are used for food packaging film and wire covers. You see them in car parts and plumbing tubes. Window frames and electrical pipes also use these plastics.

We have machines for making pipes, sheets, and straps. You pick the best plastic for your job. Our machines help you get good results every time.

Key Benefits

Using our extrusion machines gives you many good things. The table below lists the main benefits:

Advantage | Description |

High Efficiency and Productivity | Continuous production reduces time and boosts output. |

Consistent Product Quality | Automated systems minimize defects and lower costs. |

Material Versatility | One machine can make many products, saving you money. |

Tip: When you make things without stopping, you waste less. You spend less time setting up and make more products.

Modern controls help keep heat and pressure steady. This means you get less waste and better quality. You can change settings fast with smart control panels. Every batch comes out with the same high quality.

"We picked Qingdao Zhongrui Plastic Machinery for our PVC pipe line. The machine works well and always makes great pipes. Their team helps quickly and fixes problems fast."

— Mr. Li, Factory Manager

Our machines let you keep up with changes in the market. You can use many plastics and meet different needs. You work faster and save money.

You can see how an extruder machine works step by step. First, it feeds plastic into the machine. Then, the plastic melts inside. Next, the machine shapes the melted plastic. After that, it cools the plastic to make products. This process helps make pipes, sheets, and packaging straps quickly and accurately. Factories use extrusion to make better products and cut down on waste. It also helps protect the environment.

Extrusion technology is growing in building, car making, and packaging. You can count on it to save energy and work with many materials. This helps you keep up with changes in the market.

Benefit | Description |

Efficiency | Makes things faster, wastes less |

Versatility | Works with many materials and jobs |

Sustainability | Uses less energy, helps recycling |

FAQ

What materials can you process with an extruder machine?

You can use plastics like PE, PVC, PP, PET, and PMMA. These plastics are good for making pipes, sheets, profiles, and packaging straps.

How do you choose the right extruder machine?

Think about what material you want to use. Decide what shape you need for your product. Figure out how much you want to make. Single-screw extruders are best for easy jobs. Twin-screw extruders are better for mixing many things.

What maintenance does an extruder machine need?

Clean the barrel and screw often. Check the heaters and control systems. Make sure safety features work well. Regular care helps your machine work better.

Can you automate the extrusion process?

Yes! New extruder machines have smart control systems. You can set everything on a touch screen. Automation helps you make better products and saves time.

Where do you use extruded plastic products?

Extruded products are used in building, packaging, farming, and cars. Pipes, sheets, and straps help you build things, pack items, and move goods.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province