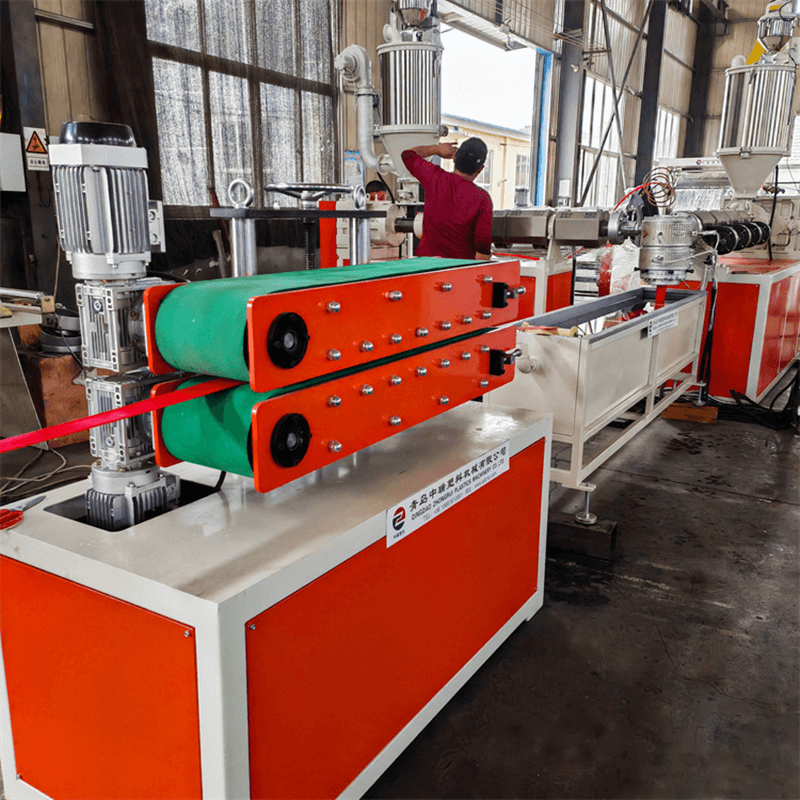

Product Overview

The PVC Layflat Fire Hose Making Machine Production Line is a state-of-the-art manufacturing solution designed to produce high-performance layflat fire hoses for critical fire safety and industrial applications. Equipped with advanced extrusion and weaving technology, this production line integrates material processing, extrusion, reinforcement, and cooling into a seamless automated workflow. It specializes in manufacturing hoses with consistent wall thickness, excellent flexibility, and superior pressure resistance, meeting international standards for fire suppression equipment. With a production speed of up to 50 meters per minute, this line ensures efficient mass production while maintaining strict quality control over every hose’s structural integrity. Whether for municipal fire departments, industrial facilities, or emergency services, this machinery delivers durable, kink-resistant hoses capable of withstanding extreme operating conditions.

Product Features

High-Pressure Resistance

The production line utilizes a multi-layer extrusion process, combining PVC compounds with high-tensile polyester yarn reinforcement. This results in fire hoses with a working pressure of 16 bar and a burst pressure exceeding 48 bar, ensuring reliable performance during high-intensity firefighting operations.

Precision Control System

Equipped with a Siemens PLC control panel and Omron temperature sensors, the line maintains precise control over extrusion temperatures (150°C–190°C) and weaving tension. This automation minimizes material waste by 15% compared to traditional systems and ensures uniform hose dimensions with a tolerance of ±0.1mm.

Durability Enhancement

Post-extrusion processes include a specialized cooling bath and UV-resistant coating application, enhancing the hose’s resistance to aging, chemical corrosion, and abrasion. The hoses produced exhibit a service life of over 10 years under normal operating conditions.

Flexible Production Capabilities

The line supports customization of hose diameters ranging from 25mm to 200mm and lengths up to 100 meters per roll, accommodating diverse customer requirements for both domestic and industrial fire safety applications.

Applications

This production line caters to a wide range of sectors, including:

Municipal Fire Services: Producing hoses for fire trucks and hydrant systems.

Industrial Facilities: Manufacturing hoses for chemical plants, refineries, and power stations where fire risk mitigation is critical.

Maritime Safety: Supplying hoses for shipboard fire suppression systems, designed to resist saltwater corrosion.

Construction Sites: Providing temporary fire hoses for on-site emergency response during building projects.

FAQ

What materials are compatible with this production line?

The line processes food-grade PVC granules and recycled PVC materials (up to 30% recycled content) without compromising hose performance. Raw materials must have a moisture content below 0.3% to ensure extrusion quality.

What is the typical production capacity?

Under standard operating conditions, the line achieves a daily output of 8,000 meters when producing 50mm diameter hoses.

Does the line include quality testing equipment?

Yes, an integrated pressure testing station checks every 10th hose for leaks at 24 bar pressure, ensuring compliance with ISO 9001 standards.

What is the warranty coverage?

The machinery comes with a 24-month warranty for core components (extruder, motor, PLC), with 12 months of free on-site maintenance support.

|

Model | | | |

| | | |

Cooling water(m3/h) | | | |

| | | |

Overall size(L*W*H)(mm) | | | |

Weight(kg) | | | |

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province