Description

Crafted for versatility, the machine processes a range of materials, including blends of SBR, NR, EPDM, NBR, and PVC, resulting in hoses that excel in harsh environments. Its design focuses on delivering lightweight yet robust products with quick output rates, zero leakage, and exceptional resistance to abrasion, corrosion, ozone, and ultraviolet radiation. Suitable for temperatures ranging from -20℃ to 80℃ (and up to 150℃ for high-temperature applications), these hoses are ideal for critical sectors such as oil fields, chemical processing, fire-fighting, agricultural irrigation, and water/sewage transportation.

Product Specifications

The PVC hose production line is available in multiple models, each tailored to different production needs. Key specifications are outlined below:

Mould | Screw Diameter (mm) | L/D | Material | Motor Power (kw) | Install Power (kw) | Height (mm) | Hose Diameter (mm) |

SJ-65 | 65 | 30 | 38CrMnAl | 15 | 28 | 1100 | 25-75 |

SJ-90 | 90 | 30 | 38CrMnAl | 37 | 52 | 1100 | 75-152 |

SJ-120 | 120 | 30 | 38CrMnAl | 55 | 75 | 1100 | 102-200 |

Features

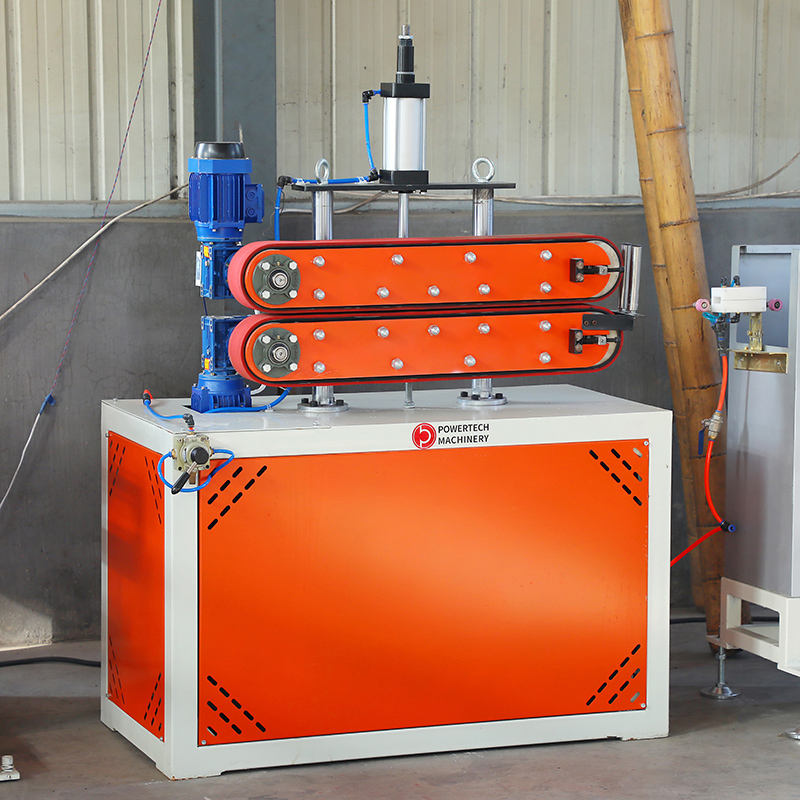

Advanced Extrusion System

At the core of the production line is a high-performance extrusion system, featuring a specialized screw and barrel design made from 38CrMnAl. This setup ensures efficient melting and homogenization of PVC materials, guaranteeing uniform density and a smooth surface finish for the hoses. Equipped with precise temperature control, the system adapts to various material formulas, preventing degradation and maintaining optimal processing conditions. The result is hoses with an impressive thickness tolerance of as low as ±0.1mm, meeting the strictest quality standards.

Multi-functional Molding & Calibration

Flexibility is a hallmark of this production line, thanks to its interchangeable die system. Operators can easily switch between dies to produce hoses in diverse shapes and sizes, including round, flat, and corrugated designs. The calibration unit combines water cooling and sizing sleeves to ensure dimensional accuracy, enabling customization for both standard and application-specific requirements. This adaptability makes the line suitable for small-batch custom orders and large-scale mass production alike.

Automated Quality Control

To minimize waste and ensure consistency, the line integrates an automated quality control system. Online sensors continuously monitor critical parameters such as hose diameter, wall thickness, and surface defects during production. Any deviation from set standards triggers real-time alerts, and the system can automatically adjust production parameters or reject defective products. This proactive approach ensures that only high-quality hoses—free from flaws—reach the end user.

Application

Industrial Sector

In industrial settings, hoses produced by this line are widely used for fluid transportation, including chemicals, oils, and water in factories. Their corrosion resistance makes them ideal for handling aggressive substances, while high-pressure tolerance ensures safe operation in pneumatic systems, where they transmit compressed air for machinery and equipment.

Agriculture & Horticulture

For agricultural and horticultural use, these hoses are indispensable in irrigation systems. They withstand prolonged exposure to sunlight, moisture, and temperature fluctuations, ensuring long-term reliability in fields. Their flexibility simplifies installation around crops, and a smooth inner surface reduces water resistance, optimizing water distribution. They also excel in pesticide and fertilizer spraying, contributing to improved crop yields.

Household & Construction

In domestic and construction environments, the hoses are valued for their lightweight design and durability. They are commonly used for plumbing, gardening, and cleaning tasks—from connecting water faucets to washing driveways. Their resistance to wear and tear ensures longevity, making them a cost-effective choice for daily and construction-related applications.

Backed by Qingdao Zhongrui’s expertise in plastic machinery, this Polyester Thread Knitting Reinforced PVC Layflat Hose Making Machine combines innovation and reliability, making it a top choice for businesses seeking efficient, high-quality PVC hose production solutions.

![PVC Hose Production Line PVC Hose Production Line]()

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province