Choosing the right piping material is one of the most important decisions in any plumbing, industrial, or infrastructure project. Among plastic pipes, the comparison of PVC vs CPVC Pipes is especially critical, because a wrong choice can lead to leaks, failures, and costly downtime. In this guide, you will learn how PVC and CPVC differ, how to install each step by step, and why the quality of the PVC Pipe Production Line behind the product directly affects your installation success.

Why PVC vs CPVC Pipes Matters Before You Install

PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) look similar at first glance, but they behave quite differently in real-world systems. PVC is widely used for cold water, drainage, and low-temperature applications, while CPVC is engineered to withstand higher temperatures and, in many cases, higher pressures.

Before cutting the first pipe or opening a can of solvent cement, you must decide whether PVC or CPVC is fit for your water temperature, pressure, and chemical environment. This decision shapes the rest of the project: the fittings you buy, the cement you use, and the way you support the system. It also determines long-term reliability and compliance with local plumbing codes.

Quick Comparison: PVC vs CPVC Pipes

To help you decide quickly, here is a concise comparison of PVC vs CPVC Pipes in the areas most relevant to installation and performance.

Material and composition: PVC is a thermoplastic made from vinyl chloride monomer. CPVC is PVC that has been chlorinated, which alters its structure and boosts its temperature and chemical resistance.

Temperature rating: PVC is usually limited to cold or moderately warm water. CPVC is designed for hot water service and can handle significantly higher temperatures, making it suitable for domestic hot water and many industrial processes.

Pressure capability: At elevated temperatures, CPVC maintains strength better than PVC. For cold water at ambient temperatures, both can offer strong pressure ratings when correctly selected.

Chemical resistance: Both materials resist many common chemicals, but CPVC often performs better with aggressive or hot fluids.

Fittings and cements: Pipes, fittings, primer, and solvent cement are not universally interchangeable. CPVC requires its own approved cement, and often a different primer, than PVC.

Common uses: PVC is favored for irrigation, drain lines, and cold water distribution. CPVC is chosen when hot water, higher temperatures, or more demanding conditions are involved.

In short, PVC is typically the cost-effective choice for cold water and drainage, while CPVC is the safer option for higher temperatures. Understanding these differences is the foundation for correct installation.

Understanding PVC Pipes Before Installation

PVC pipe is one of the most widely used plastics in construction and infrastructure. Knowing its characteristics helps you design and install systems that last.

Key Properties of PVC Pipes

PVC is lightweight, rigid, and naturally resistant to corrosion, making it ideal for environments where metals would corrode or scale. It offers:

High resistance to many chemicals and soils

Low internal friction, allowing smooth water flow

Non-conductive properties, useful for electrical conduit

Long service life under proper operating conditions

PVC pipes are typically classified by schedule (such as Schedule 40 or 80) or by pressure rating. These labels indicate wall thickness and the amount of pressure the pipe can safely handle at a specified temperature.

Common Applications for PVC Pipes

Because of its reliability and cost-effectiveness, PVC is common in:

Cold water distribution systems

Drain, waste, and vent (DWV) lines

Irrigation and agricultural networks

Non-pressure conduit for electrical wiring

In each of these roles, proper installation techniques are essential to get the most from the material.

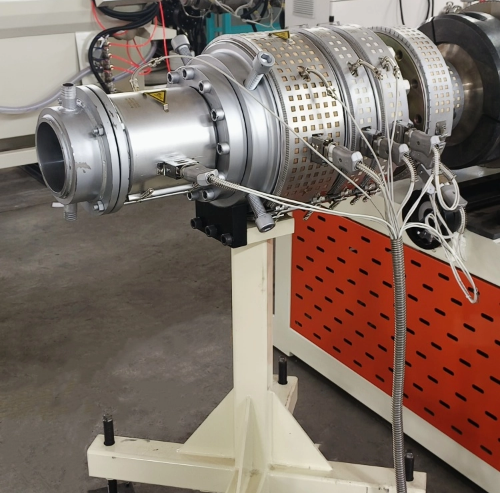

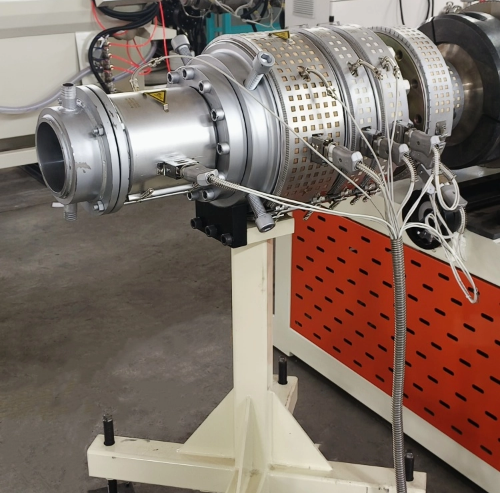

The Role of the PVC Pipe Production Line

The integrity of a PVC pipe begins long before it reaches your job site. In a modern PVC Pipe Production Line, raw materials are mixed, melted, and extruded into pipe, then cooled and cut to length. High-quality production lines control:

Wall thickness and uniformity: Consistent walls prevent weak spots and help fittings grip properly.

Pipe roundness: Round pipes fit evenly into fittings, creating strong solvent-welded joints.

Surface smoothness: Smooth internal walls reduce friction loss and scaling, while smooth external surfaces help ensure complete cement coverage.

When you install pipes manufactured on a precise PVC Pipe Production Line, you benefit from easier cutting, accurate fit-up, and fewer installation issues related to dimensional inconsistencies.

Understanding CPVC Pipes Before Installation

CPVC is a close relative of PVC but is formulated to perform where PVC reaches its limits. It is especially useful in hot water and demanding chemical environments.

Key Properties of CPVC Pipes

CPVC is produced by chlorinating PVC resin, increasing its chlorine content. This change offers:

Higher allowable service temperatures compared to PVC

Improved strength at elevated temperatures

Enhanced resistance to certain chemicals and disinfectants

Because CPVC remains stable and strong where PVC may soften or deform, it is widely selected for hot water distribution and many industrial piping systems.

Common Applications for CPVC Pipes

Typical uses of CPVC include:

Residential and commercial hot and cold potable water lines

Industrial fluid handling in moderate chemical and temperature ranges

Specialized systems such as certain fire protection or process lines (where permitted by code)

These applications put more stress on the piping system, which means installation techniques must be carefully followed.

CPVC vs PVC from a Production Perspective

Producing CPVC pipe on a PVC Pipe Production Line often requires adjustments in processing temperatures, cooling rates, and quality checks. Accurate control during manufacturing helps avoid internal stresses and micro-cracks that might appear later under hot water or pressure.

Installers benefit from dimensionally stable CPVC pipes: fittings slide on smoothly, solvent cement spreads evenly, and joints cure into robust, leak-resistant connections.

Tools and Materials Needed to Install PVC and CPVC Pipes

Whether you are working with PVC or CPVC, having the correct tools and materials sets the stage for a successful job.

Common Tools for PVC and CPVC Installation

Pipe cutter or fine-tooth saw for clean, straight cuts

Deburring tool or utility knife to remove burrs and rough edges

Measuring tape and marker for accurate layout

Clean cloths to remove dust, dirt, and moisture

Pipe supports and clamps to maintain alignment

Specific Consumables for Each Material

Although PVC vs CPVC Pipes may look similar, they do not use the same chemical joining products.

For PVC: Use PVC primer (as required by code) and PVC solvent cement, along with PVC-rated fittings such as elbows, tees, couplings, and valves.

For CPVC: Use primer explicitly approved for CPVC if required, CPVC-specific solvent cement, and CPVC-rated fittings and transition adapters.

Mixing materials or using incorrect cements is one of the most common causes of joint failure, so always confirm product labels and manufacturer instructions.

Step-by-Step Guide: Installing PVC Pipes

The following procedure covers typical solvent-welded PVC installations for cold water or drainage systems.

1. Plan the PVC Pipe Layout

Start by sketching the route of your pipe. Mark all changes in direction, tee junctions, and transitions to existing lines. Consider:

Required slope for drainage lines

Pipe sizing for expected flow and pressure

Locations of valves and cleanouts for maintenance

Compliance with local building and plumbing codes

2. Measure and Cut the PVC Pipe

Measure the length between fittings and mark the pipe clearly. Use a pipe cutter or fine-tooth saw to cut the pipe at a right angle. Straight cuts ensure full contact between pipe and fitting, which is essential for strong solvent-welded joints.

3. Deburr and Clean the Pipe Ends

After cutting, remove all burrs and rough edges inside and outside the pipe. Burrs can create turbulence, trap debris, and prevent the pipe from fully seating in the fitting. Wipe the pipe and fitting socket with a clean cloth to remove dust, grease, and moisture.

4. Dry Fit the Components

Assemble the section without primer or cement to check alignment and ensure the pipe seats fully in each fitting. Mark the orientation of fittings and pipes so you can quickly assemble them in the same positions once you apply cement.

5. Apply Primer and PVC Solvent Cement

If primer is required in your region, apply it first to the outside of the pipe end and inside the fitting socket. Allow it to soften the surfaces briefly. Then apply PVC solvent cement evenly to both primed surfaces, using the applicator provided. Avoid excessive cement that can pool or drip inside the pipe.

6. Assemble and Hold the Joint

Immediately push the pipe into the fitting while twisting a quarter turn to distribute the cement. Hold the joint firmly for several seconds to prevent it from backing out as the cement begins to set. Wipe away excess cement from the outside of the joint.

7. Allow Curing and Perform Initial Testing

Follow the cement manufacturer’s instructions for set and cure times, which vary with pipe size and temperature. Once the recommended time has passed, perform a low-pressure test, checking all joints for any signs of leaks. Correct any issues before closing walls or burying the lines.

Step-by-Step Guide: Installing CPVC Pipes

Installing CPVC is similar to PVC, but the higher operating temperatures and different chemistry call for extra care in product selection and handling.

1. Design the CPVC System Layout

Plan separate lines or branches for hot and cold water where required. Keep hot lines away from sensitive materials and allow space for insulation. Confirm that CPVC is approved for your intended use under local codes.

2. Cut and Deburr CPVC Pipe

Use an appropriate cutter or saw that will not crush or crack CPVC. Make sure every cut is square. Deburr the ends as you would with PVC, removing all sharp edges and shavings that could interfere with proper seating or flow.

3. Clean and Prepare Surfaces

Wipe the pipe and fitting sockets with a clean, dry cloth. For systems under higher stress, cleanliness becomes even more important, because any contamination can weaken the solvent-welded bond under hot water conditions.

4. Use CPVC-Specific Primer and Cement

Apply primer approved for CPVC if it is part of the system requirements. Then use CPVC-specific solvent cement, which is formulated for the material’s chemistry and temperature range. Applying the wrong cement can result in brittle or weak joints that fail prematurely.

5. Assemble CPVC Joints

Insert the pipe into the fitting with a turning motion, similar to PVC. Hold each joint in place for the time recommended by the cement manufacturer so that it does not move while the bond forms. Larger diameters may require a longer hold time.

6. Cure and Pressure-Test for Hot Water Service

Allow full curing time before introducing pressure, especially in hot water lines. After curing, gradually pressurize the system and raise the water temperature in stages. Inspect all joints carefully for seepage. Any sign of leakage must be addressed immediately before the system is put into regular service.

Key Installation Differences Between PVC and CPVC

While installation procedures for PVC vs CPVC Pipes look similar, some differences have a major impact on long-term performance.

Temperature and Pressure Effects

In hot water systems, CPVC maintains its strength and shape where PVC may soften or warp. This means support spacing, expansion allowances, and joint design must all consider temperature. CPVC systems must be supported and routed so that thermal expansion does not stress joints over time.

Joining Materials and Compatibility

PVC cement is not suitable for CPVC unless explicitly approved, and generic multi-purpose cements may not meet code or performance standards. Always use products that are clearly labeled for the material being joined. Transition fittings may be needed when joining PVC to CPVC or other materials.

Code and Certification Considerations

Local codes often specify where PVC or CPVC may be used, particularly for potable water and hot water lines. Look for markings on the pipe indicating conformity to recognized standards and check that your installation method matches manufacturer recommendations and regulatory requirements.

Maintenance and Long-Term Performance

Both materials can provide long service lives if installed correctly. However, CPVC systems exposed to constant high temperatures or aggressive water chemistry may require more careful periodic inspection. Early signs of stress, such as discoloration around joints or small leaks, should be dealt with promptly.

The Impact of the PVC Pipe Production Line on Installation Quality

Behind every reliable installation is a production process that controls dimensions and material quality. A well-designed PVC Pipe Production Line contributes directly to easier and more durable assemblies in the field.

Dimensional Accuracy and Tolerance Control

Production lines that tightly control diameter, wall thickness, and roundness allow fittings to slip on with the right amount of interference. This ensures that solvent cement can form an even, continuous bond. Pipes that are out of round or inconsistent in size can be difficult to assemble and may create weak spots at joints.

Surface Finish and Structural Integrity

A smooth exterior surface allows primer and cement to spread evenly. A smooth interior surface reduces friction and discourages salt or scale buildup. Advanced extrusion and cooling methods in a PVC Pipe Production Line help prevent internal voids and micro-cracks that could later expand under pressure and temperature cycles.

Why Installers Should Choose Quality Pipes

When evaluating products for a project, look for signs of quality manufacturing:

Consistent color and rigidity along the length of the pipe

Clear, durable markings for size, schedule, and standards

Minimal warping or visible defects on the surface

Quality pipes from a reliable production line not only install more easily but also provide peace of mind once the system is in operation.

Common Mistakes When Installing PVC vs CPVC Pipes

Avoiding typical errors can dramatically increase system reliability and reduce the need for rework.

Using the Wrong Material for the Application

Installing PVC in a hot water or high-temperature chemical line where CPVC or another material is required can lead to deformation and leaks. On the other hand, over-specifying CPVC where simple cold-water PVC would suffice may increase costs without added benefit.

Incorrect Primer or Solvent Cement

Using the wrong cement or skipping primer where it is required can cause joint failure. Always match primer and cement to the material, system pressure, and temperature range. Do not assume one product works for everything.

Poor Cutting, Deburring, and Alignment

Uneven cuts, leftover burrs, and forcing pipes into misaligned fittings all put stress on joints. Over time, these stresses can lead to cracks or leaks, especially in CPVC systems under thermal cycling.

Insufficient Curing and Testing

Pressurizing a system before solvent cement has cured is a frequent cause of leaks. Respect cure times, then test the system under realistic operating conditions, including temperature where applicable, before closing access to the pipes.

How to Choose Between PVC vs CPVC Pipes

To select the right material, consider operating conditions, environment, and long-term costs, not just initial price per meter.

Evaluate Operating Conditions

Temperature: If the system carries hot water or experiences high ambient temperatures, CPVC is typically safer.

Pressure: Check both materials’ pressure ratings at the maximum operating temperature.

Fluid type: Consider chemical compatibility with any additives, disinfectants, or process chemicals.

Consider Installation Environment and Budget

For exposed outdoor installations, you may need UV protection for PVC, such as paint or shielding. CPVC may also require protection and support to accommodate thermal expansion. Compare overall system costs, including fittings, cements, supports, and labor, rather than focusing only on pipe prices.

Weigh Long-Term Reliability and ROI

A correctly chosen and installed CPVC system can prevent failures in hot water or demanding industrial applications. Conversely, well-installed PVC can offer excellent value in cold-water and drainage systems. In both cases, pipes made on a high-quality PVC Pipe Production Line will help reduce leaks, callbacks, and maintenance costs, improving the long-term return on your investment.

Viewpoints from Different Platforms on PVC vs CPVC Pipes

Various reference and language platforms describe PVC and CPVC in slightly different ways, highlighting different aspects of the comparison.

Merriam-Webster Platform

This platform focuses on clear definitions of materials, distinguishing PVC and CPVC as separate forms of plastic. The emphasis is on using accurate technical terms when discussing plumbing or industrial systems so that the difference between PVC vs CPVC Pipes is not lost in vague language.

Wiktionary Resource

This resource emphasizes how abbreviations such as PVC and CPVC are used in technical and everyday language. It notes that the two acronyms are not interchangeable, underlining that each refers to a distinct material with its own characteristics and typical applications.

Collins Dictionary Platform

Here, PVC and CPVC are presented as different types of synthetic piping materials. The descriptions usually associate PVC with general-purpose, often cold-water systems, while CPVC is linked to hot water or higher-performance uses, underscoring that the choice between them has practical consequences.

Oxford Learner’s Resource

This learner-focused source treats PVC and CPVC as specialized vocabulary important for students in engineering or building trades. It stresses that understanding the practical distinction between PVC vs CPVC Pipes is vital when reading technical manuals or following installation instructions.

Dictionary Reference

In this reference, PVC and CPVC are defined as related but distinct plastics, used for pipes and fittings. The entries generally connect PVC with standard plumbing and building works, while CPVC is mentioned as a material adapted for higher temperature or more demanding service, reminding users that material choice affects system safety.

Cambridge Dictionary Platform

This platform highlights the technical use of these terms in professional English. It points out that when discussing plumbing or mechanical systems, professionals deliberately specify whether they are using PVC or CPVC, because the difference implies specific performance limits and installation requirements.

Free Dictionary Resource

This resource tends to go deeper into the chemical and engineering background of both materials. The explanations describe how the different chlorine content influences temperature resistance and chemical compatibility, reinforcing the idea that the PVC vs CPVC Pipes decision is central to safe and durable system design.

FAQs About Installing PVC and CPVC Pipes

Can I connect PVC and CPVC together in one system?

Yes, but only with properly designed transition fittings and cements approved for joining the two materials. You must also respect local codes and manufacturer guidelines when combining materials.

Is CPVC always the better choice?

Not necessarily. CPVC excels in hot water and higher temperature applications, but PVC is often more economical and perfectly suitable for cold water, drainage, irrigation, and many non-potable systems.

How do I know which solvent cement to use?

Check the label on the cement for compatibility with PVC, CPVC, or both. Also confirm that it is rated for the pipe size and pressure conditions of your system. When in doubt, follow the recommendations from the pipe and cement manufacturers.

Can I run PVC or CPVC pipes outdoors?

Yes, but additional protection is often required. PVC should typically be shielded from direct sunlight or painted with a compatible coating. CPVC also needs proper support, protection from impact, and allowance for thermal expansion in exposed locations.

Does the PVC Pipe Production Line really affect installation?

Absolutely. Pipes produced on a precise, well-controlled production line have more consistent dimensions and fewer defects, which makes them easier to cut, fit, and solvent-weld. This translates directly into fewer leaks and less rework during and after installation.

Conclusion: From Production Line to Finished System

The decision between PVC vs CPVC Pipes is more than a choice of color or brand. It determines how your system handles temperature, pressure, and chemical exposure. Combined with high-quality products from a reliable PVC Pipe Production Line, careful planning and proper installation practices will give you a piping system that is efficient, durable, and compliant with applicable codes.

By understanding the differences between PVC and CPVC, using the correct tools and materials, and following step-by-step installation procedures, you can build systems that perform reliably for years with minimal maintenance and downtime.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province